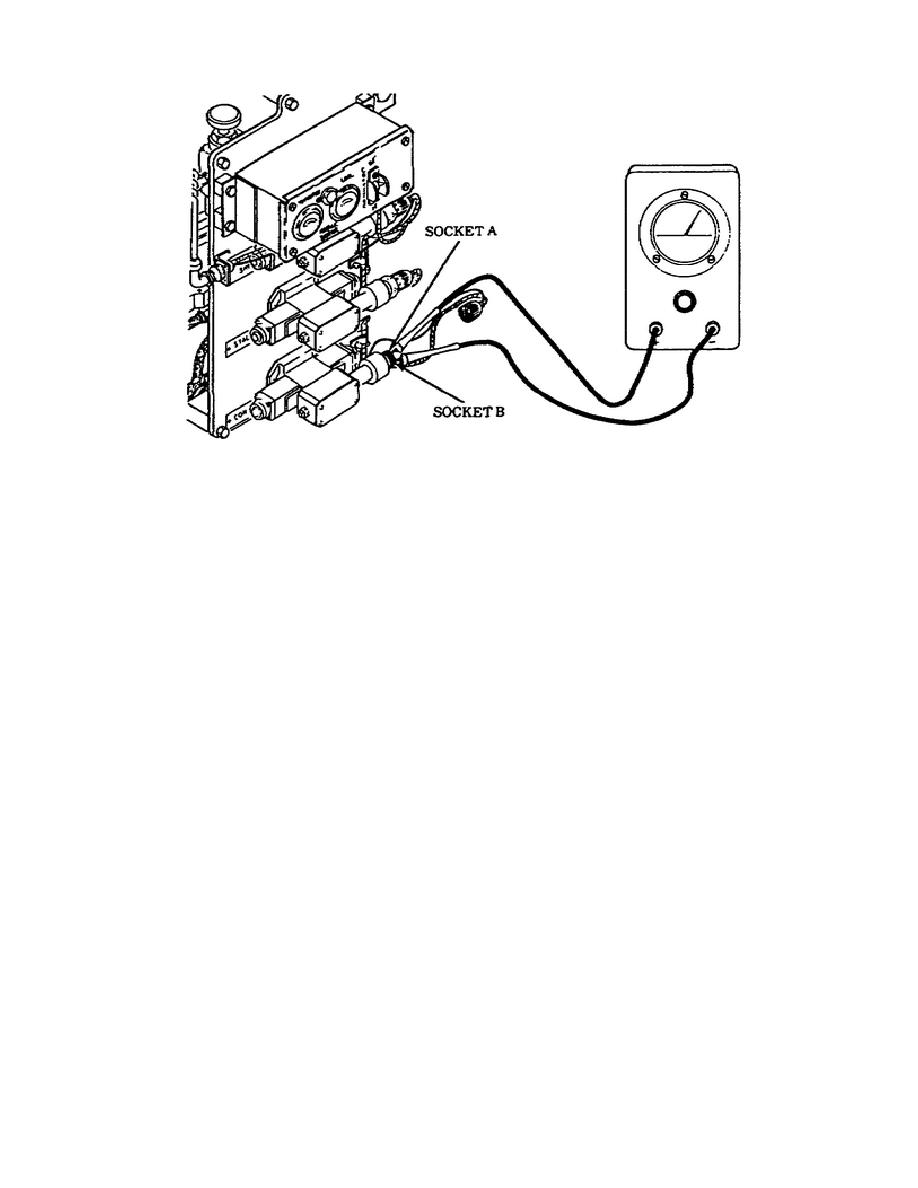

Figure 40.

Solenoid Resistance Test Point.

The next problem you will troubleshoot in the conveyor system is the conveyor moves

in one direction only.

o Shut down the hydraulic system, insert the handcrank in the conveyor, and

manually operate the conveyor system. If the conveyor does not move easily

one full cycle in both directions, you must troubleshoot the chain is jammed

or broken. However, the conveyor assembly moved in both directions and you

must continue to troubleshoot.

o Set the MASTER switch to the ON position and start the primary or backup

hydraulic system. Manually operate the conveyor directional control valve in

both directions (Fig. 30). If the directional control valve does not operate

the system in both directions it must be replaced. If it operates correctly

in both directions, activate the directional control valve using the

direction control switch on the hydraulic control panel (Fig. 29).

If the

switch fails to activate the directional control valve, you must troubleshoot

the electrical system.

The next problem you will troubleshoot in the conveyor system is the conveyor chain

is jammed or broken.

o Check the conveyor chain and sprocket alignment.

Check the chain for

binding, breakage, or other damage and inspect the chain path for

obstructions.

Check the chain drive sprocket for missing, worn, or bent

teeth; replace or repair as required.

43

OD1737

Previous Page

Previous Page