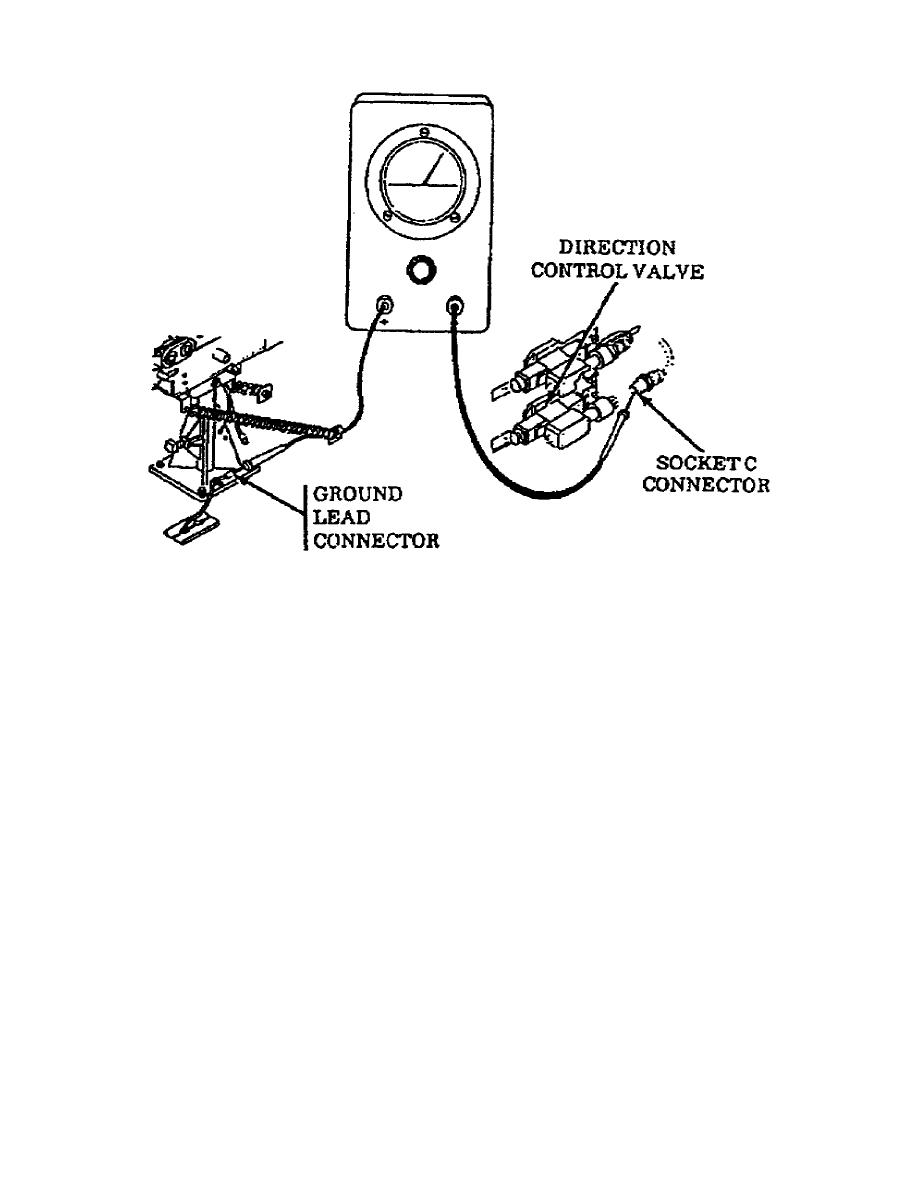

Figure 38.

Conveyor Harness Test Points.

o Shut down the hydraulic system and disconnect the hydraulic oil

lines from the conveyor motor.

Install a tee connector and

pressure gage between the oil lines (Fig. 40F).

Start the

primary or backup hydraulic system and operate the conveyor

system in both directions.

The pressure gage must indicate

pressure in both directions. If line pressure was indicated in

one direction only, you must repair or replace the hydraulic oil

lines from the motor to the hydraulic control panel. If pressure

is indicated in both directions, the conveyor hydraulic motor

must be replaced.

You located the hydraulic problem in the conveyor system that caused the

conveyor chain not to move. Backup one step to where you assumed the

problem was hydraulic not electrical. Assume the problem is electrical

and troubleshoot the electrical system.

o Set the MASTER switch to the OFF position and disconnect the

hydraulic control panel connector. Turn the MASTER switch to the

ON position. Using a multimeter, check for voltage by placing

the red probe in socket B and

45

OD1703

Previous Page

Previous Page