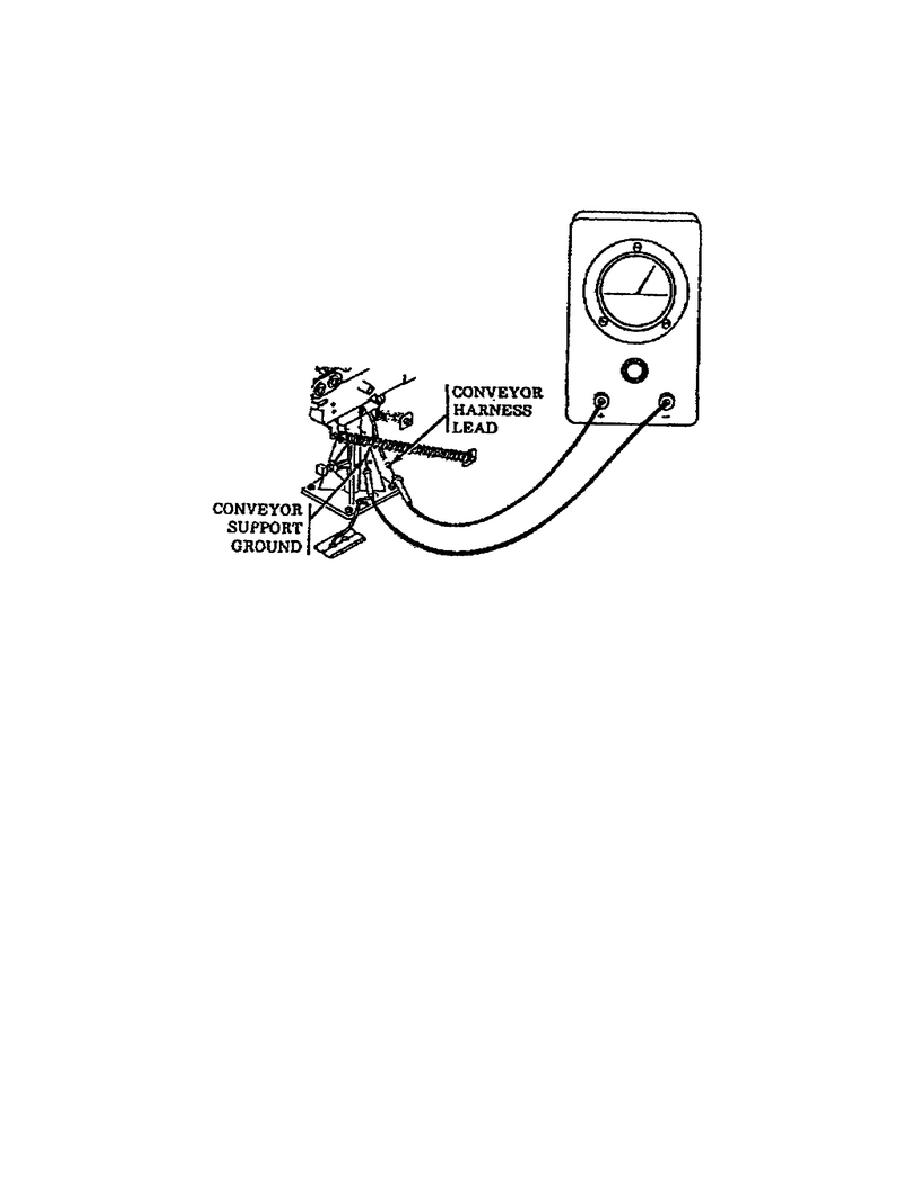

o Disconnect the conveyor harness and test for continuity between

the conveyor harness lead and support ground (Fig. 37).

If

continuity is not indicated in the conveyor harness lead, it is

defective and must be replaced.

With continuity indicated,

continue troubleshooting.

Figure 37.

Conveyor Harness Lead.

o Disconnect the harness connector at the conveyor directional

control valve and test the continuity between the pin C connector

and the ground lead connector (Fig. 38).

If there is no

continuity indicated, the lead is defective and you must notify

support maintenance.

If continuity is indicated, connect the

harness connector at the conveyor directional control valve and

the conveyor support.

Continue to troubleshoot the conveyor

system.

o Set the MASTER switch to the ON position and start the primary or

backup hydraulic system.

Manually operate the conveyor

directional control valve in both directions (Fig. 39F). If the

valve does not operate the system in both directions it must be

replaced.

If the directional control valve operated correctly

in both directions, activate it with the direction control switch

on the hydraulic control panel (Fig. 39F). If the switch fails

to activate the directional control valve, you must troubleshoot

the electrical system.

Assume the directional control valve

operated correctly, the conveyor control switch activated the

valve, and continue to troubleshoot the hydraulic system.

44

OD1703

Previous Page

Previous Page