(c) Cutting extremely heavy gage metal always presents an opportunity to

spring the blades. Once the blades are sprung, hand snips are useless. Use the

rear portion of the blades only when cutting heavy material. This not only avoids

the possibility of springing the blades but also gives you greater cutting leverage.

(d) It is hard to cut circles or small arcs with straight snips. There

are snips especially designed for circular cutting. They are called hawk-bill

snips and aviation snips. Use these snips in the same manner as you would use

straight snips and observe the same precautions. Like straight snips they come in

many different sizes.

(e) Many snips have small serrations (notches) on the cutting edges of

the blades. This tends to prevent them from slipping backwards when a cut is being

made. Although this feature does make the actual cutting much easier, it mars the

edges of the metal slightly. You can remove these small cutting marks if you allow

proper clearance for dressing the metal to size. There are many other types of

hand snips used for special jobs. The snips discussed here can be used for almost

any common type of work.

(f) Learn to use snips properly. They should always be oiled and

adjusted to permit ease of cutting and to produce a surface that is free from burs.

If the blades bind, or if they are too far apart, the snips should be adjusted.

(g) Never use snips as screwdrivers, hammers, or pry bars. They break

easily. Do not attempt to cut heavier materials than the snips are designed for.

Never toss snips in a toolbox where the cutting edges can come into contact with

other tools. This dulls the cutting edges and may even break the blades. When

snips are not in use, hang them on hooks or lay them on an uncrowded shelf or

bench. Never use tin snips to cut hardened steel wire or other similar objects.

Such use will dent or nick the cutting edges of the blades.

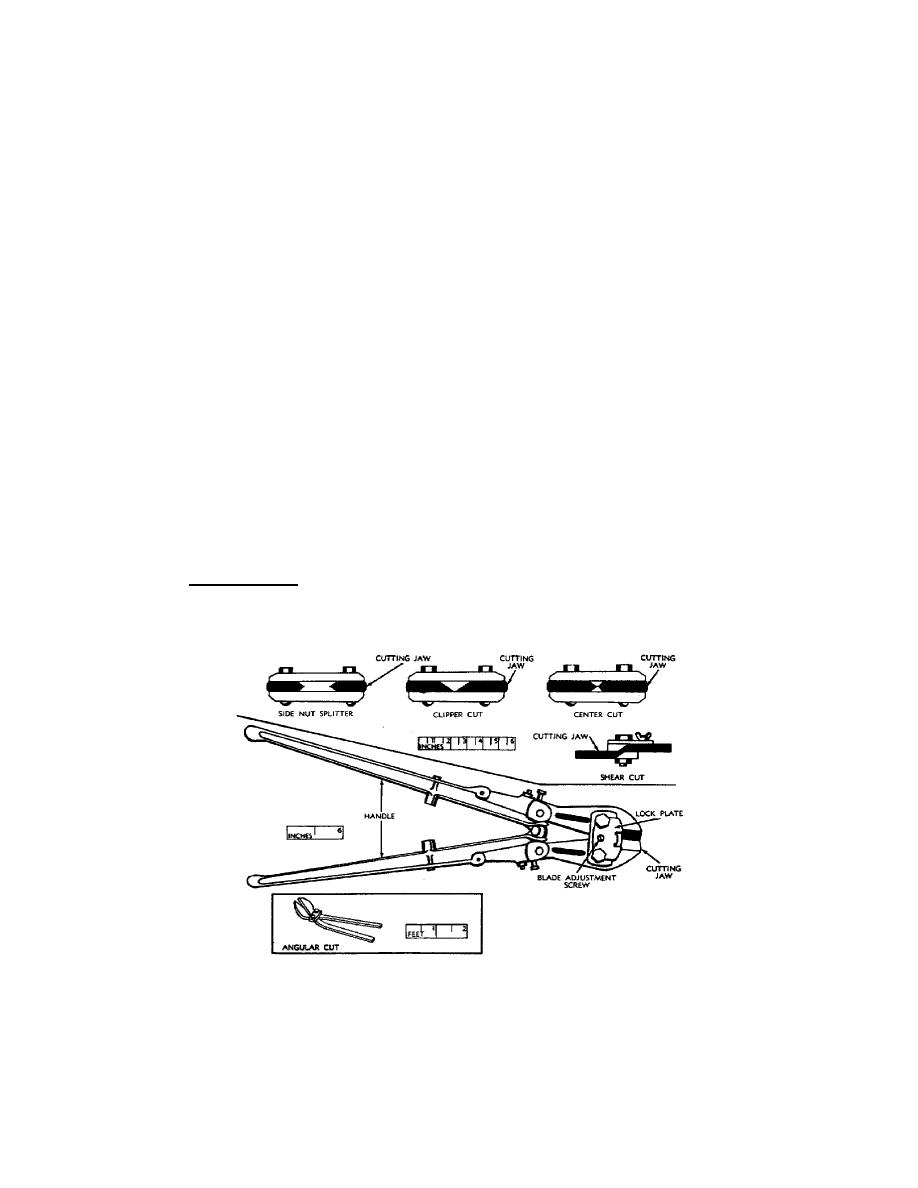

(2) Bolt cutters. Bolt cutters (fig 38) are used to cut bolts, rod, wire

rope, cable, screws, rivets, nuts, bars, strips, and wire. A bolt cutter is shaped

like a giant shears with short blades and long handles. Different cutting edges

are designed for specific applications.

Figure 38.

Types of bolt and nut cutters.

33

Previous Page

Previous Page