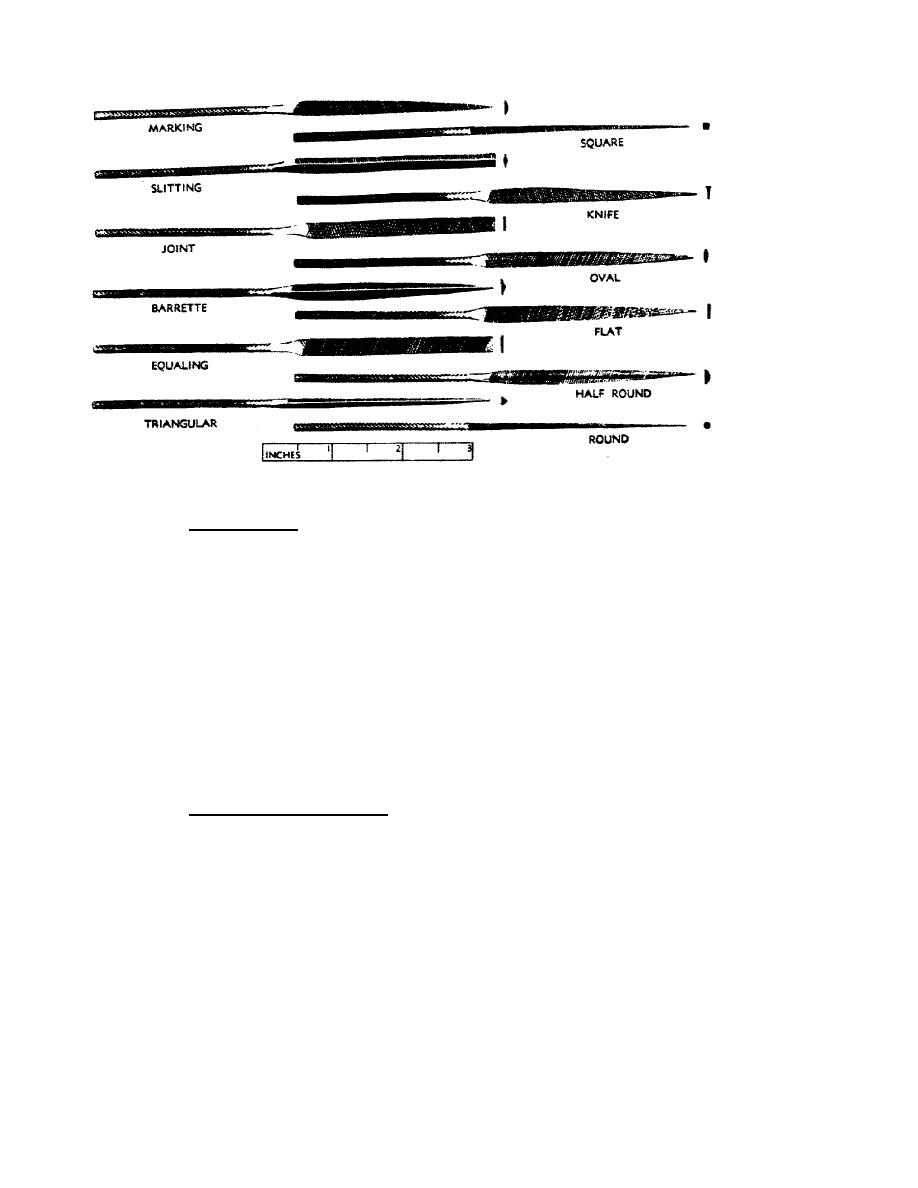

Figure 36.

Swiss pattern files.

(4) Use of files. There are thousands of kinds, cuts, and sizes of files.

This is due to the fact that there are thousands of different filing jobs, each of

which can be done better by using the right file for the job. Therein lies the

first rule on how to get the most out of files. The right file enables doing the

job properly, whereas the wrong one does not and often, in fact, ruins the work.

The right file saves time because it performs correctly, and usually faster, on the

kind of metal or work for which it was designed. The right file permits a greater

number of efficient filing strokes. Many factors enter into the selection of the

right file for the job. In general, it may be said that different files are

required to file a flat or convex surface; to file a curved or concave surface; to

file an edge; to file a notch, a slot, or a square or round hole. But these

factors can immediately become complicated by the kind of metal or other material

to be filed; the kind, shape, and hardness of the object or part to be filed; the

location, size, and character of the surface, edge, notch, slot, or hole to be

filed; the amount of metal to be removed; and the degree of smoothness or accuracy

required. All these conditions have a bearing on the kind, size, and cut of file

which will best attain a particular objective.

(5) Selecting proper file.

(a) For heavy, rough cutting, a large coarse, double cut file is best.

(b) For finishing cuts, use a second cut or smooth cut, single cut file.

(c) When working on cast iron, start with a bastard cut file and finish

with a second cut file.

(d) When filing soft metal, start with a second cut.

(e) When filing hard steel, start with a smooth cut file and finish with

a dead smooth file.

29

Previous Page

Previous Page