(3) Care of shears and cutters. Keep tools clean at all times. Lubricate

pivot screw or bolt with a drop of light oil. Remove rust with a fine aluminum

oxide abrasive cloth. Apply a thin film of oil on tools to prevent rust, and hang

tools on hooks or place them on a shelf when not in use. Never throw tools in a

box where the cutting edges may be damaged. Do not attempt to cut material harder

than the tool was designed to handle. Never use shears or cutters as a hammer or a

pry bar, since they are easily damaged. For long periods of storage, coat tools

with a rust preventive compound and store them in a dry place where the cutting

edges do not come in contact with other metal objects.

e. Chisels.

(1) Chisels are tools that can be used for chipping or cutting metal. They

are made from a good grade tool steel with a hardened cutting edge and a beveled

head. They will cut any metal that is softer than materials of which they are

made. When it is skillfully used, the chisel can be made to do most any job that a

milling machine can do, although it is perhaps less accurate and requires greater

time and energy.

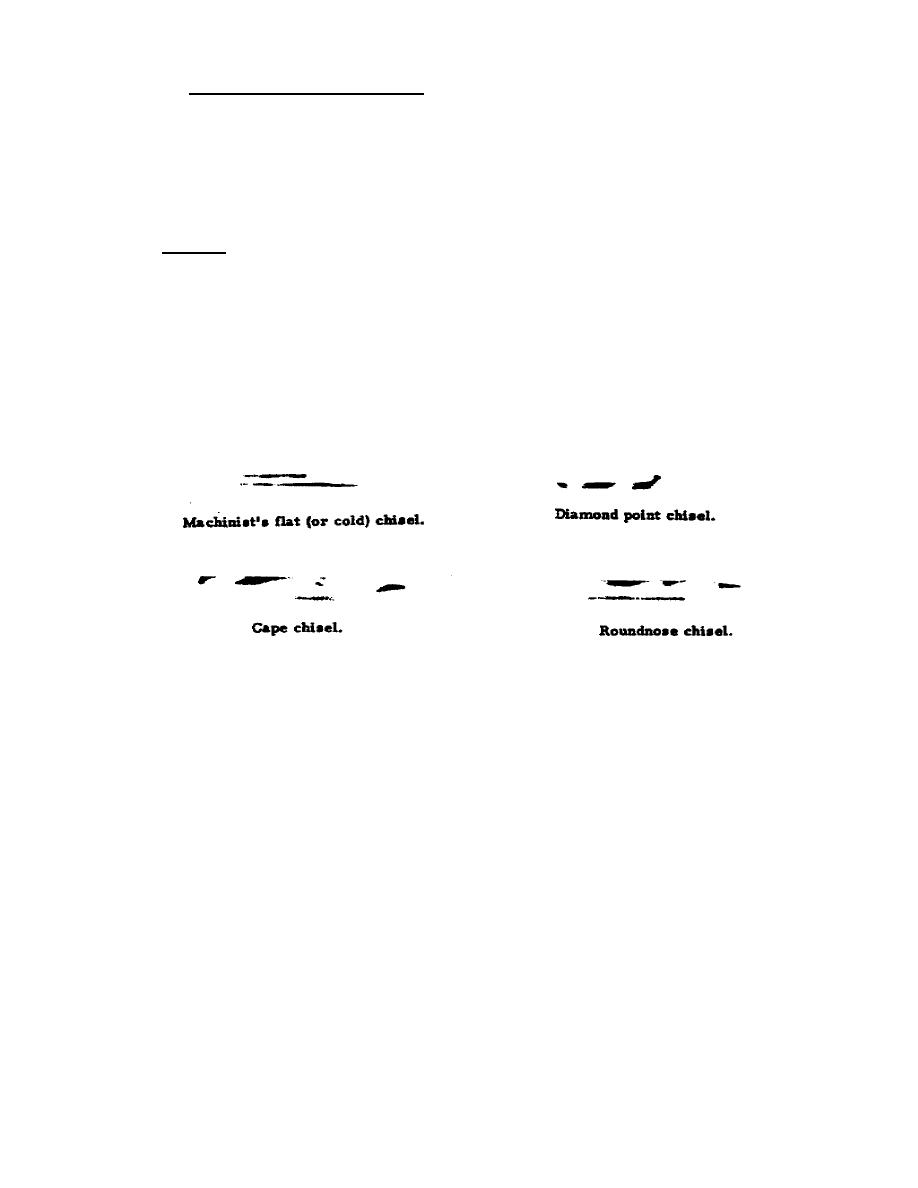

(2) Usually the bar stock from which a chisel is forged is octagonal

(eight-sided). Cold chisels are classified according to the shape of their points,

and the width of the cutting edge denotes their size. The most common shapes of

chisels are flat (cold chisel), cape, roundnose, and diamond point (fig 39).

Figure 39.

Chisels.

(3) The type chisel most commonly used is the flat cold chisel which serves

to cut rivets, split nuts, chip castings, and cut thin metal sheets. Also used for

special jobs is the cape chisel for cutting keyways, narrow grooves, and square

corners; the roundnose chisel for semicircular grooves and for chipping inside

corners with a fillet; and the diamond point for cutting V-grooves and sharp

corners.

(4) As with other tools there is a correct technique for using a chisel.

Select a chisel that is large enough for the job. Be sure to use a hammer that

matches the chisel; that is, the larger the chisel the heavier the hammer. A heavy

chisel will absorb the blows of a light hammer and will do virtually no cutting.

As a general rule, hold the chisel in the left hand with the thumb and first finger

about 1 inch from the top. It should be held steadily but not tight. The finger

muscles should be relaxed, so if the hammer strikes the hand it will slide down the

tool and lessen the effect of the blow. Keep the eyes on the cutting edge of the

chisel, not on the head, and swing the hammer in the same plane as the body of the

chisel. If you have a lot of chiseling to do, slide a piece of rubber hose over

the chisel. This will lessen the shock to your hand.

34

Previous Page

Previous Page