(5) When using a chisel for chipping. always wear goggles to protect your

eyes. If other men are working close by, see that they are protected from flying

chips by erecting a screen or shield to contain the chips. Remember that the time

to take these precautions is before you start the job.

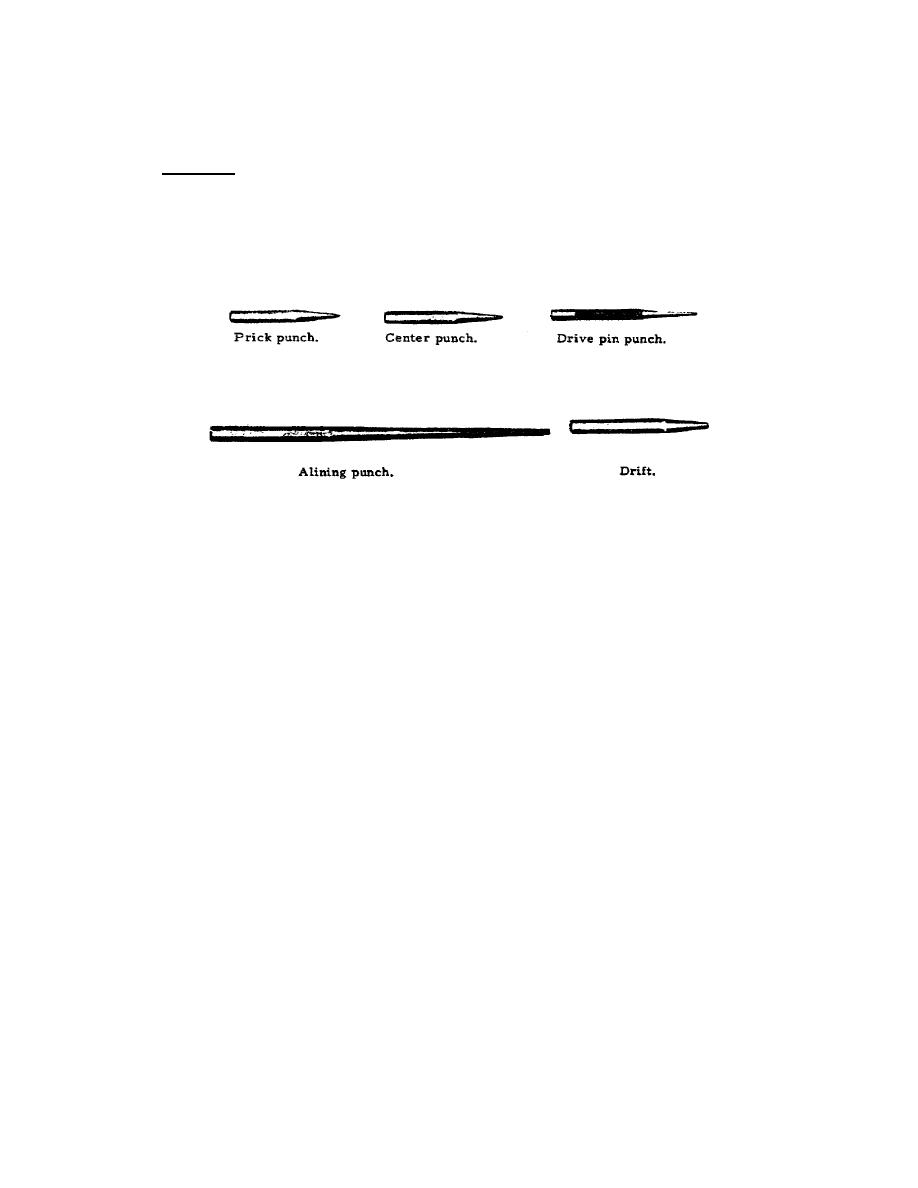

f. Punches.

(1) A hand punch is a tool that is held in the hand and struck on one end

with a hammer. There are many kinds of punches designed to do a variety of jobs

and most are made of tool steel. The part held in the hand is usually octagonal

shaped or it may be knurled. This prevents the tool from slipping around in the

hand. The other end is shaped to do a particular job. Figure 40 shows some of the

most common used metal punches.

Figure 40.

Commonly used metal punches.

(2) Drift punches, sometimes called "starting punches", have a long taper

from the tip to the body. They are made that way to withstand the shock of heavy

blows. They may be used for knocking out rivets after the heads have been chiseled

off, or for freeing pins which are "frozen" in their holes. After a pin has been

loosened or partially driven out, the drift punch may be too large to finish the

job. The followup tool to use is the pin punch, for it is designed to follow

through the hole without jamming. Always use the largest drift or pin punch that

will fit the hole. These punches usually come in sets of three to five assorted

sizes and will have flat points, never edged or rounded. To remove a bolt or pin

that is extremely tight, start with a drift punch that has a point diameter

slightly smaller than the diameter of the object you are removing. As soon as it

loosens, finish driving it out with a pin punch. Never use a pin punch for

starting a pin, because it has a slim shank and a hard blow may cause it to bend or

break.

(3) Another punch you will use a lot is the center punch. As the name

implies, it is used for marking the center of a hole to be drilled. If you try to

drill a hole without first punching the center, the drill will "wander" or "walk

away" from the desired center. Another use of the center punch is to make

corresponding marks on two pieces of an assembly to permit reassembly in their

original positions. The point of a center punch is accurately ground central with

the shank, usually at a 60 angle, and is difficult to regrind by hand with any

degree of accuracy. It is, therefore, advisable to take care of a center punch and

not to use it on extremely hard materials.

(4) Other punches have been designed for special uses. One of these is the

soft-faced drift. It is made of brass or fiber and is used for such jobs as

removing shafts, bearings, and wrist pins from engines. It is generally heavy

enough to resist damage to itself, but soft enough not to injure the finished

surface on the part that is being driven.

35

Previous Page

Previous Page