9. REPAIR. Repair consists of returning components to the minimum repair

standards and to the best possible rebuilt condition.

a. Minor scratches, burs, and dents on machined surfaces, where there is

minimum or no friction, such as the frame and housing, may be repaired by using a

fine mill file.

b. Minor rough spots, score marks, and nicks on surfaces, where friction

occurs continuously, should be repaired using a fine stone or crocus cloth dipped

in drycleaning solvent. Such surfaces are the inside bores of bronze bearings,

splines, pinion teeth, clutch contact surfaces, and the surfaces on the yoke pin.

c. The repair of the armature requires three operations: resurfacing the

commutator, undercutting the mica, and polishing the commutator.

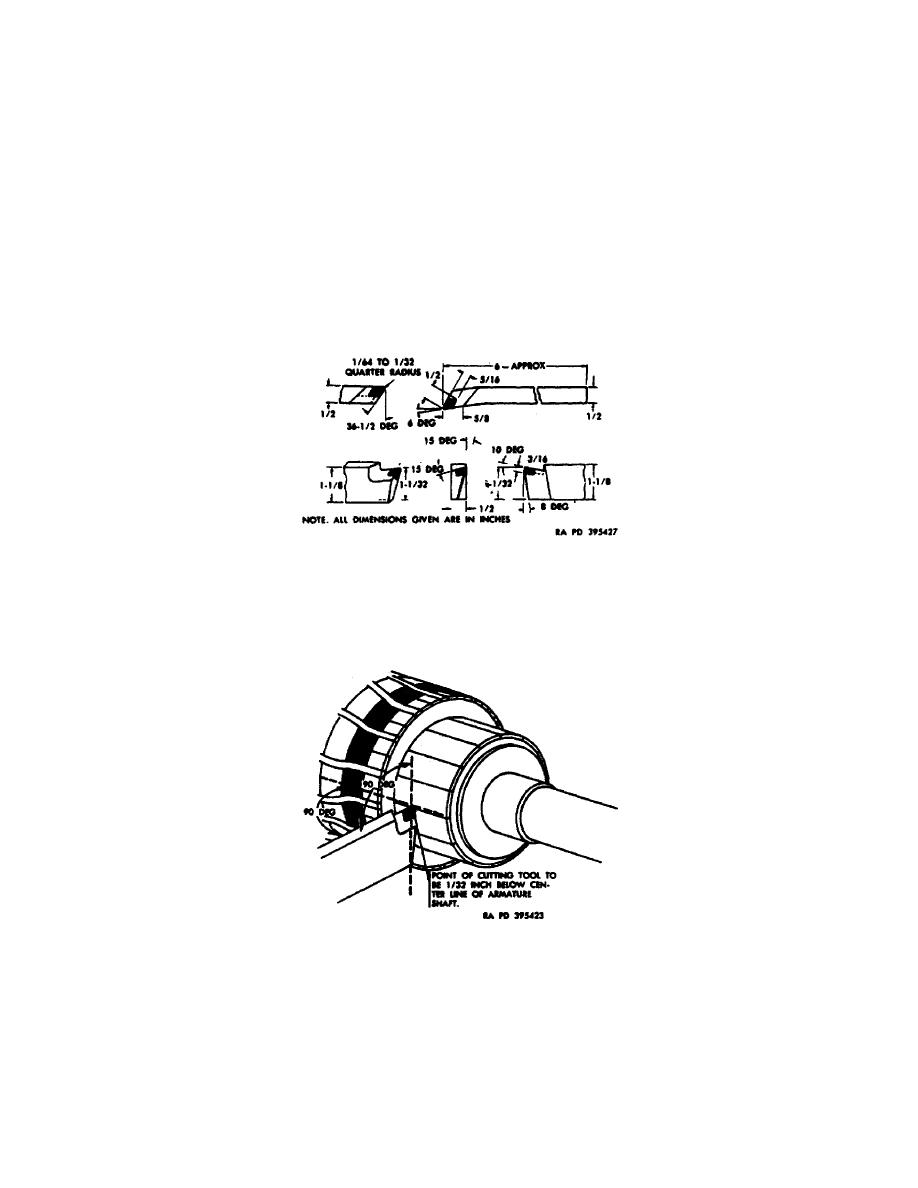

(1) Figure 22 shows the sharpening dimensions of the resurfacing tool to

be used in a lathe. After grinding, hone the tool with a fine hard stone to insure

a smooth cut during the lathe turning operation.

Figure 22.

Cutting tool.

(a) Figure 23 shows the position of the cutting tool with respect to

the commutator. With the lathe rotating the armature at 800 RPM, make very light

cuts on the commutator. No more than 0.005 inch should be removed during any one

cut and the final cut should not be more than 0.002 inch.

Figure 23.

Positioning of tool.

OS 010, 6-P19

Previous Page

Previous Page