Figure 13.

Drift punching.

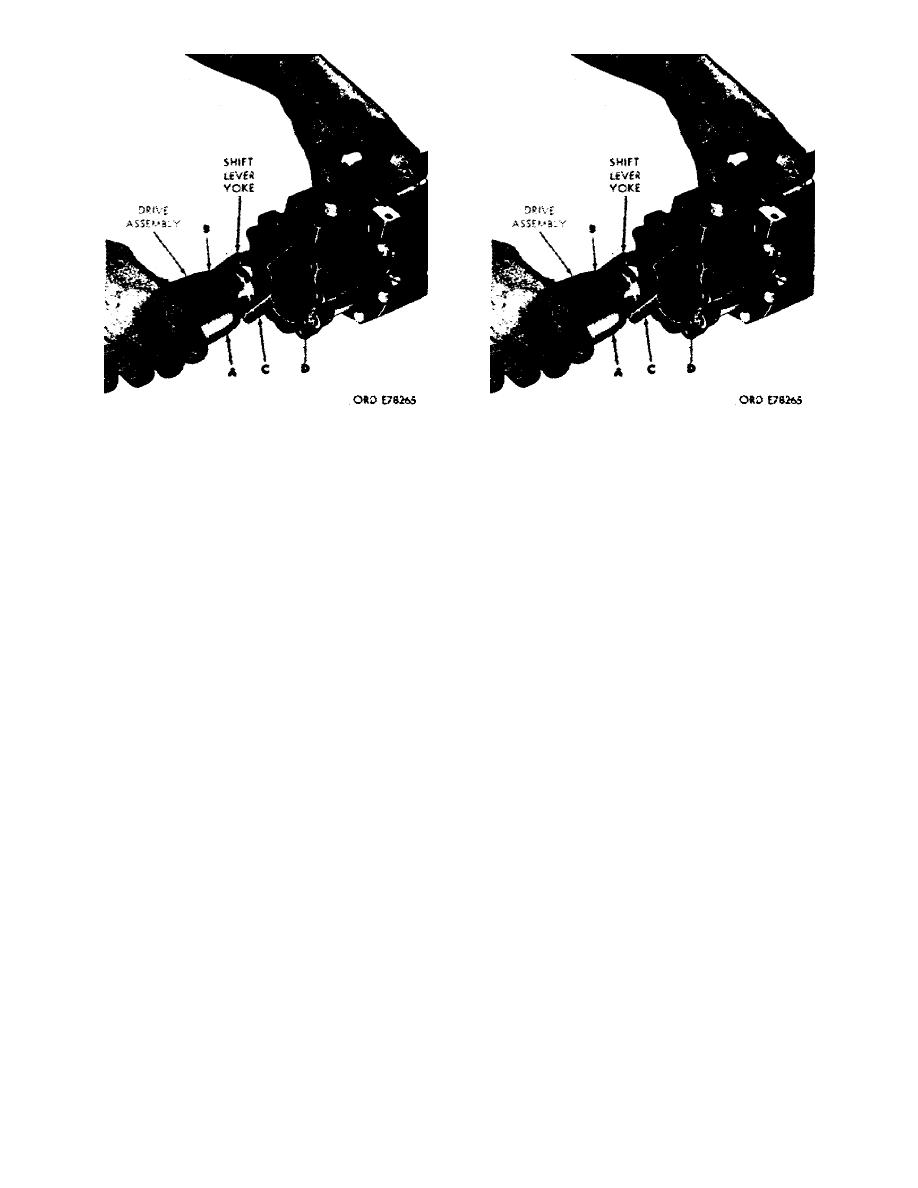

Figure 14.

Drive assembly.

h. The starter has now been disassembled into its subassemblies. In

overhauling, the subassemblies are broken down into bare parts. All rubber parts

and oil seals are discarded and replaced with new ones. All bolts, screws, nuts,

and plugs are inspected for worn or damaged threads.

7. CLEANING. Special instructions for electrical parts are detailed below.

Clean all other parts in drycleaning solvent or mineral spirits paint thinner and

dry with compressed air.

a. The field coils and frame are cleaned with a cloth dampened with

drycleaning solvent. Be careful not to damage the insulation and fungus coating.

Dry with compressed air.

b. The armature is first blown with compressed air to remove loose

particles and then wiped with a cloth dampened with drycleaning solvent. The

commutator is cleaned lightly with No 00 sandpaper. The traces of dust are removed

with low-pressure compressed air.

c. The brushes are cleaned with a dry cloth only.

Do not permit

drycleaning solvent to come in contact with the brushes.

OS 010, 6-P14

Previous Page

Previous Page