SECTION III.

MAINTENANCE

6. OVERHAUL OF PRESTOLITE STARTER. Overhaul consists of disassembly, cleaning,

inspection, repair, reassembly, and testing. Before beginning disassembly

operations, the exterior of the starter should be thoroughly washed with

drycleaning solvent or mineral spirits paint thinner and then dried with compressed

air. During the disassembly all preformed packing, gaskets, and oil seals are

discarded. They are replaced with new parts during reassembly.

a. As in most operations, there is a sequence of disassembly to be

followed. With the Prestolite starter, the first item to be removed is the pinion

housing assembly.

(1) The position of the pinion housing with respect to the intermediate

housing should be noted, so that they may be reassembled as they came apart.

Therefore, it is a normal procedure to scribe a mark on the pinion housing and the

intermediate housing to locate the relative position at assembly.

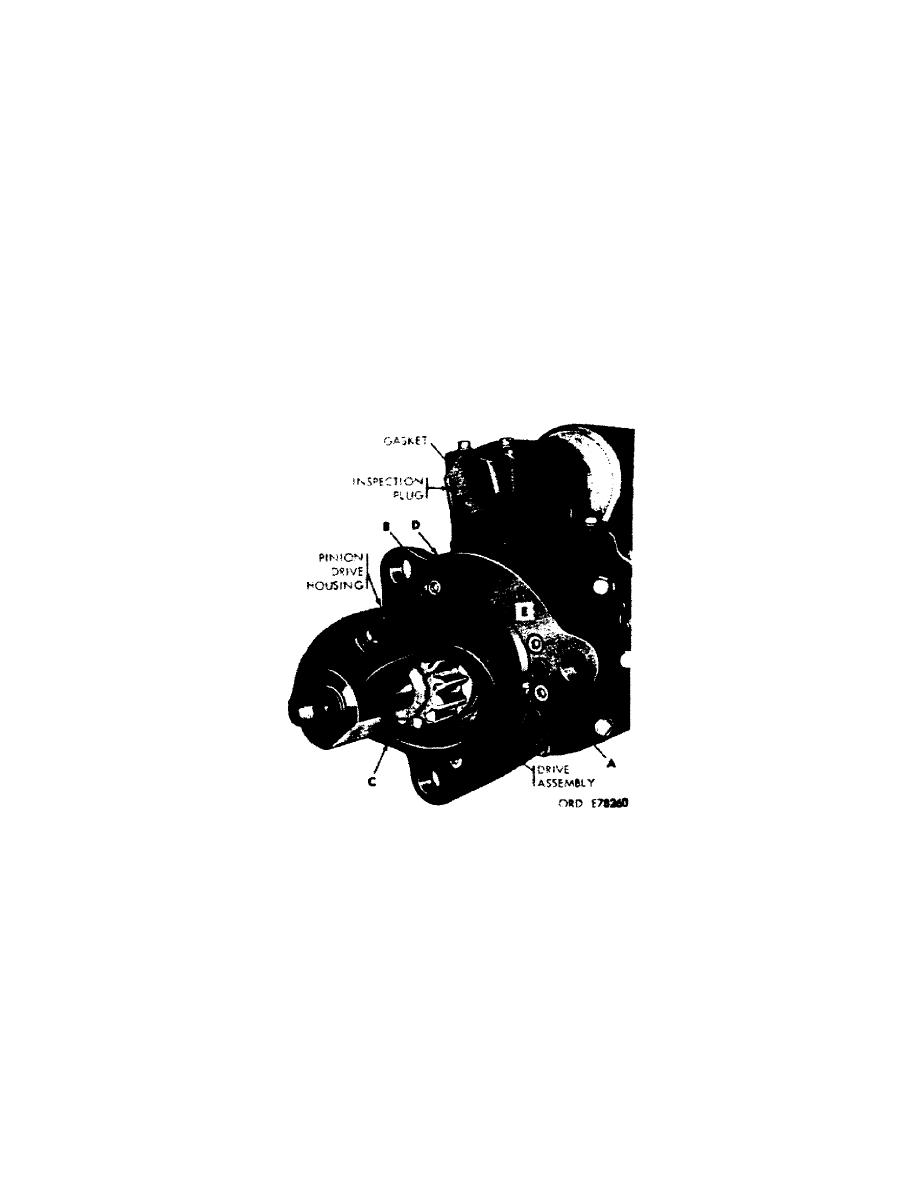

(2) Remove the six socket-head capscrews (B)(fig 9). This allows the

pinion housing to be removed from the intermediate housing with the attached

gaskets. The thrust washer (E) is loose so it should be removed from the armature

shaft.

Figure 9.

Pinion housing.

b. The drive assembly is now exposed. It would slide from the armature

shaft if it weren't for the shift lever yoke (P)(fig 8). The yoke lever must be

disconnected from the solenoid core. To do this, the inspection plug is removed to

expose the solenoid shaft (N) for removal of the solenoid assembly.

OS 010, 6-P11

Previous Page

Previous Page