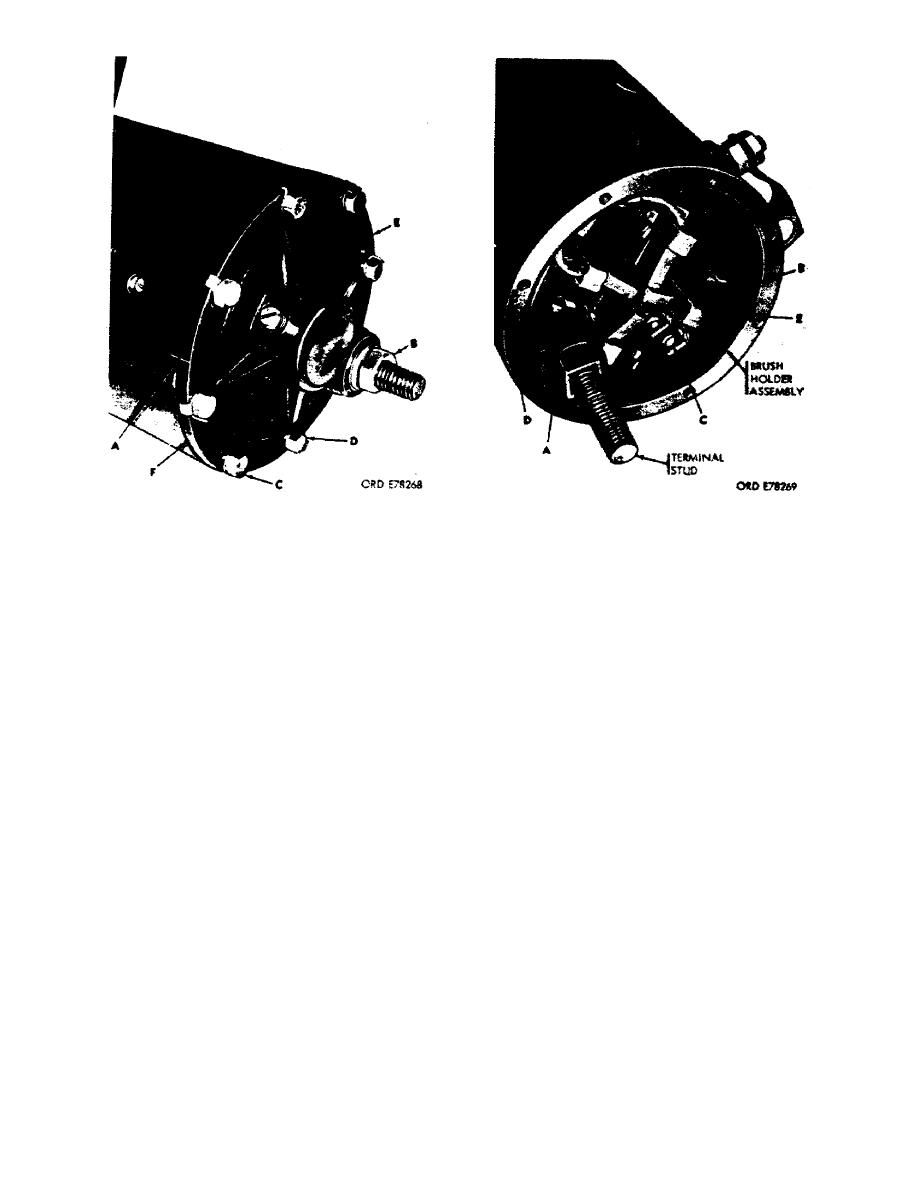

Figure 17.

Commutator end head

Figure 18.

Brush holder assembly.

assembly.

8. INSPECTION. Inspection consists of checking all components, parts, and

assemblies for damage. All machined surfaces, splines, and gear teeth are checked

for scratches, nicks, burs, and badly worn areas. Check all assemblies and parts

for conformity to repair standards as shown in foldout 2.

a. Inspect threads in tapped holes in the assembly housings and frames for

damage. If threads are stripped or damaged beyond repair, replace the item.

b. Inspect all bronze bearings for discoloration, rough spots, score marks,

scratches, nicks, and wear. Bearings must not be loose in housings. The oil wicks

are checked for tears, fraying, and wear.

c. Inspect all thrust washers for cracked or deformed conditions and proper

thicknesses. If they do not conform to repair standards or are defective, replace

them.

OS 010, 6-P16

Previous Page

Previous Page