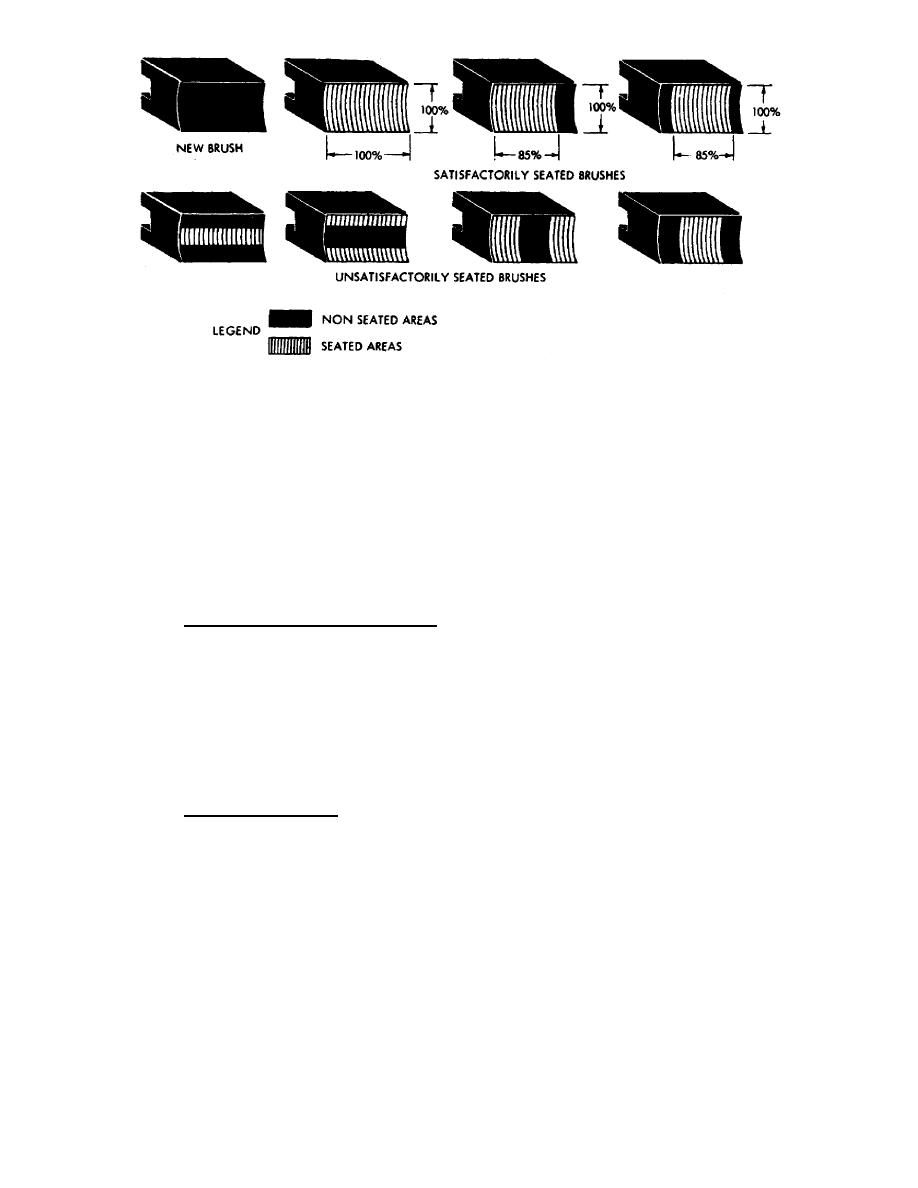

Figure 29.

Brush seats.

(4) Install the drive assembly and yoke shift lever. Put the yoke cover

in place and install the yoke pin for proper shift lever pivoting. Secure the yoke

cover, observing that all seals and packing are in place.

(5) During installation of the solenoid relay there is a rubber boot

that must be on the inside of the yoke cover and over the outside edge of the

solenoid case for proper seal. Do not install inspection plug and gasket until

final tests and adjustments are completed.

(6) Include the thrust washer during pinion housing installation. Next

aline the scribe marks on the pinion housing and intermediate housing. Torque

tighten screws to 100 pound-inches.

g. Pinion clearance adjustments. The drive assembly is adjusted for proper

shifting within the pinion drive housing. The clearance between the thrust washer

and pinion is to be from 0.020 to 0.050 inch when the solenoid is energized (fig

30).

(1) To make this adjustment the starter motor is made inactive by

disconnecting the field terminal and ground terminal on the starter frame.

(2) The solenoid is energized with a 24-volt battery. The pinion will

move forward; therefore, before making the measurement, push the pinion back toward

the armature to take up the slack movement.

h. Pinion block test. The pinion block test is a test of continuity of the

current to the starter motor. For pinion travel of greater than 0.500 inch from

the thrust washer, the solenoid contacts should be open; for less than 0.500 inch,

the contacts will be closed, thereby applying current to the motor if it is

connected.

(1) This distance is checked with a series of spacer blocks or thrust

washers and a continuity tester. Figure 31 shows the spacer block between the

pinion and thrust washer.

(2) If continuity is greater than 0.500 inch, then the pinion clearance

is adjusted to its minimum limit of 0.020 inch and the block test is performed

again to make sure an open circuit exists.

OS 010, 6-P24

Previous Page

Previous Page