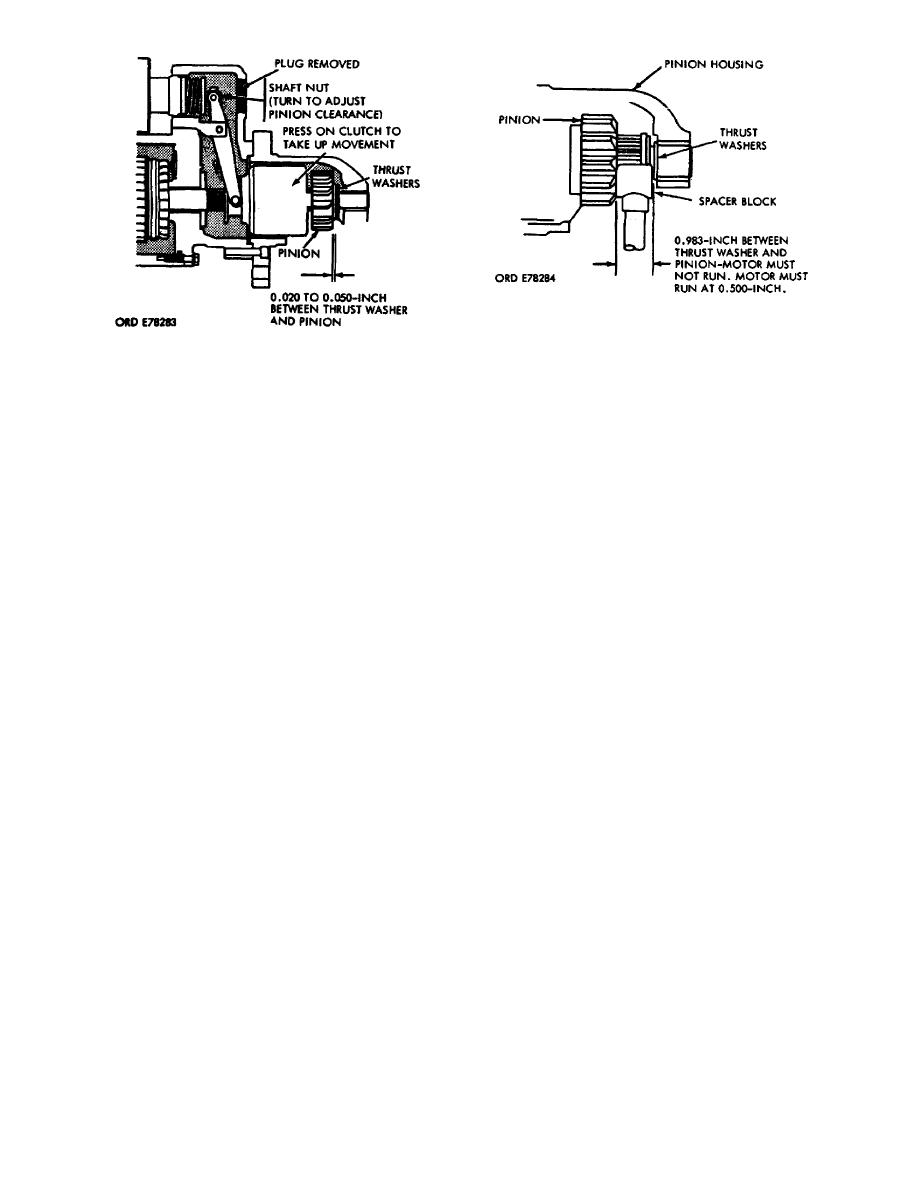

Figure 30.

Pinion clearance.

Figure 31.

Pinion block test.

i. At the completion of the clearance and block tests, restore the cables

to their normal functional connections. This completes the assembly of the starter.

SECTION IV.

TESTING

11.

TESTING. There are three types of tests used to determine starter

performance: the no load test, where the starter free runs; stall torque test,

where starter torque is measured: and a waterproof test, where the starter is

submerged in water.

CAUTION:

Never operate the starter more than 30 seconds at a time. Allow the

motor to cool for at least 2 minutes between each cranking cycle.

Overheating, caused by excessive cranking, will seriously damage the

starter motor.

a. 500-ampere test stand. The tests performed on the 500-ampere test stand

are

the NO LOAD and STALL TORQUE tests. Figure 32 shows the mounting requirements

for

stall torque testing. The starter NO LOAD or FREE RUN tests are performed with

the

starter mounted in the same manner as for the stall torque test, but without

the

torque arm.

(1) The NO LOAD test is performed to indicate the functioning of the

starter. When there is no load connected, it will run freely at a specific minimum

RPM and current drain.

(a) For the no load test, the test leads are connected between the

positive (+) field winding terminal (B, fig 33) and the ground terminal (A, fig

33). The solenoid is not energized for this test.

(b) The parallel connection to J17 and J28 on the test stand is the

input to the DC voltage meter which monitors the voltage across the starter.

(c) The DC ammeter is wired internally to indicate the starter

current. This current is controlled by knob (24), which is a variable resistance

device called a carbon pile.

OS 010, 6-P25

Previous Page

Previous Page