PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

cylinders are parallel to the adjacent sides of the bar within a close

tolerance.

Equally close tolerances control the cylinder roundness and

freedom from taper. The slots or holes in the bar are for convenience in

clamping workpieces to the bar. Although the illustrated bars are typical,

there is a wide variety of specialized shapes, widths, and thicknesses.

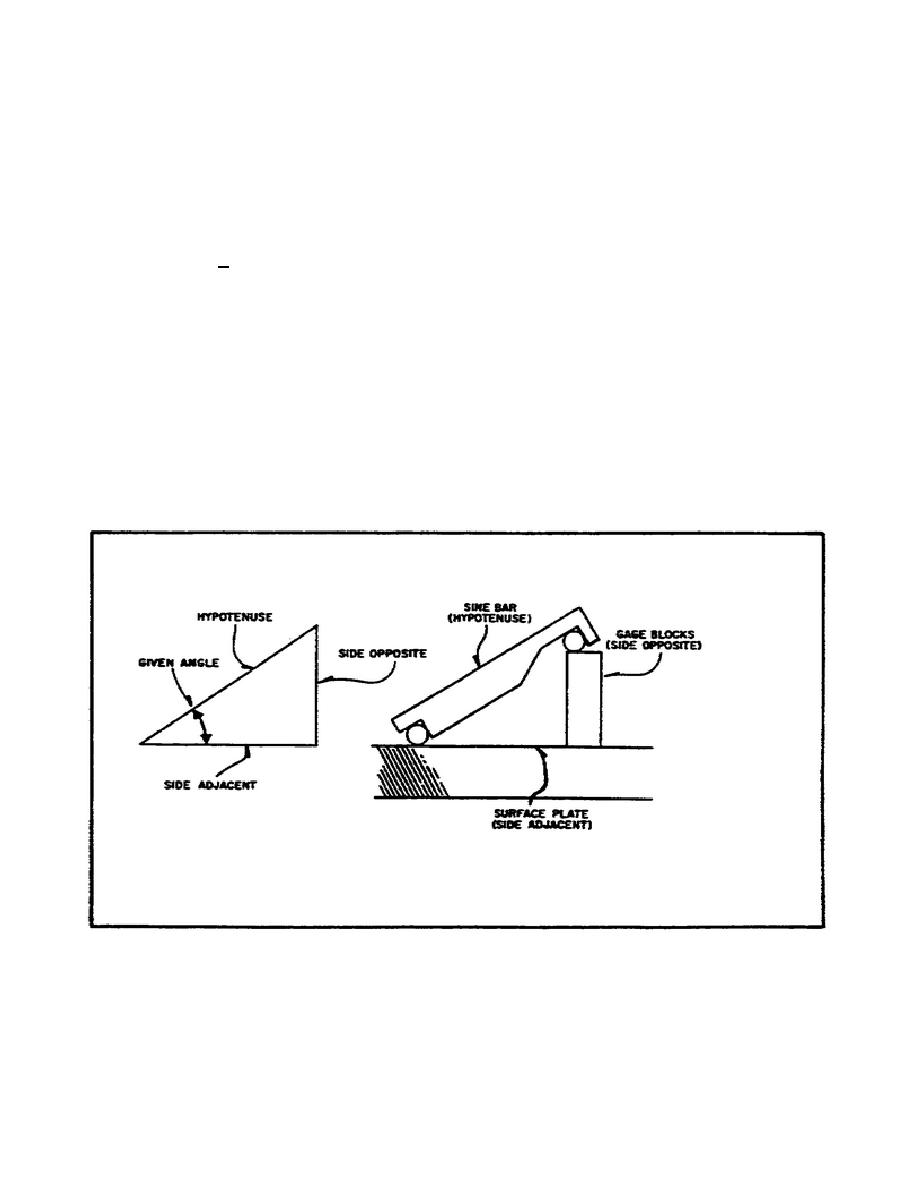

2 The sine bar itself is very easy to set up and use.

One

does not need to have a basic knowledge of trigonometry to understand how it

works.

When a sine bar is set up, it always forms a triangle.

A right

triangle has one 90ƒ angle. The base of the triangle formed by the sine bar

is the surface plate (figure 25). The side opposite is made up of the gage

blocks that raise one end of the sine bar. The hypotenuse is always formed

by the sine bar. The height of the gage block setting may be found in two

ways. The first method is to multiply the sine of the angle needed by the

length of the sine bar. The sine of the angle may be found in any table of

trigonometric functions. The second method is to use a table of sine bar

constants. These tables give the height setting for any given angle (to the

nearest minute) for a 5 inch sine bar. Tables are not normally available

for 10 inch bars because it is just as easy to use the sine of the angle and

move the decimal point to the right.

FIGURE 25.

SETUP OF THE SINE BAR.

37

Previous Page

Previous Page