PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

and convex (outside curve) radii in almost all of the common sizes.

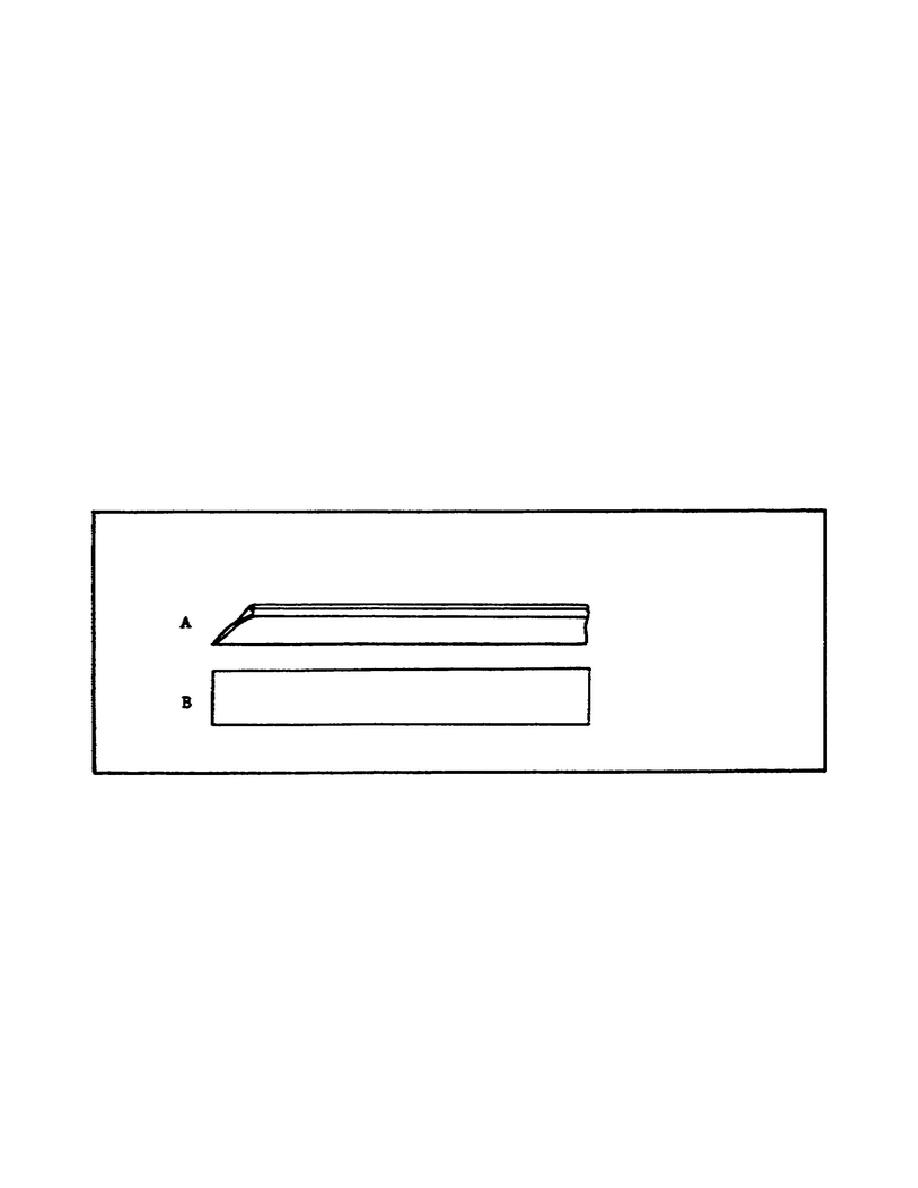

(7) Straightedges.

(a) General. Straightedges look very much like rules, except that

they are not graduated. They are used primarily for checking surfaces for

straightness; however, they can also be used as guides for drawing or

scribing straight lines. Two types of straightedges are shown in figure 23.

View A shows a straightedge made of steel which is hardened on the edges to

prevent wear; it is the one the machinist will probably use the most. The

straightedge shown in View B has a knife edge and is used for work requiring

extreme accuracy.

(b) Care. The straightedges should always be kept in a box when

they are not in use.

Some straightedges are marked with two arrows, one

near each end, which indicate the balance points.

When a box is not

provided, place the resting pads on a flat surface in a storage area where

no damage to the straightedge will occur from other tools.

Place the

straightedge so that the two balance points set on the resting pads.

FIGURE 23.

STRAIGHTEDGES.

(8) Machinist's Square. The most common type of machinist's square

is a hardened steel blade securely attached to a beam. The steel blade is

not graduated. This instrument is very useful in checking right angles and

in setting up work on shapers, milling machines, and drilling machines. The

size of the machinist's squares range from 1 1/2 to 36 inches in blade

length. The same care should be taken with them as with micrometers.

35

Previous Page

Previous Page