PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

this type is equivalent to 24 inches.

A scale, therefore, gives

proportional measurements instead of the actual measurements obtained with a

rule.

Like rules, scales are made of wood, plastic, and metal.

They

generally range from 6 to 24 inches.

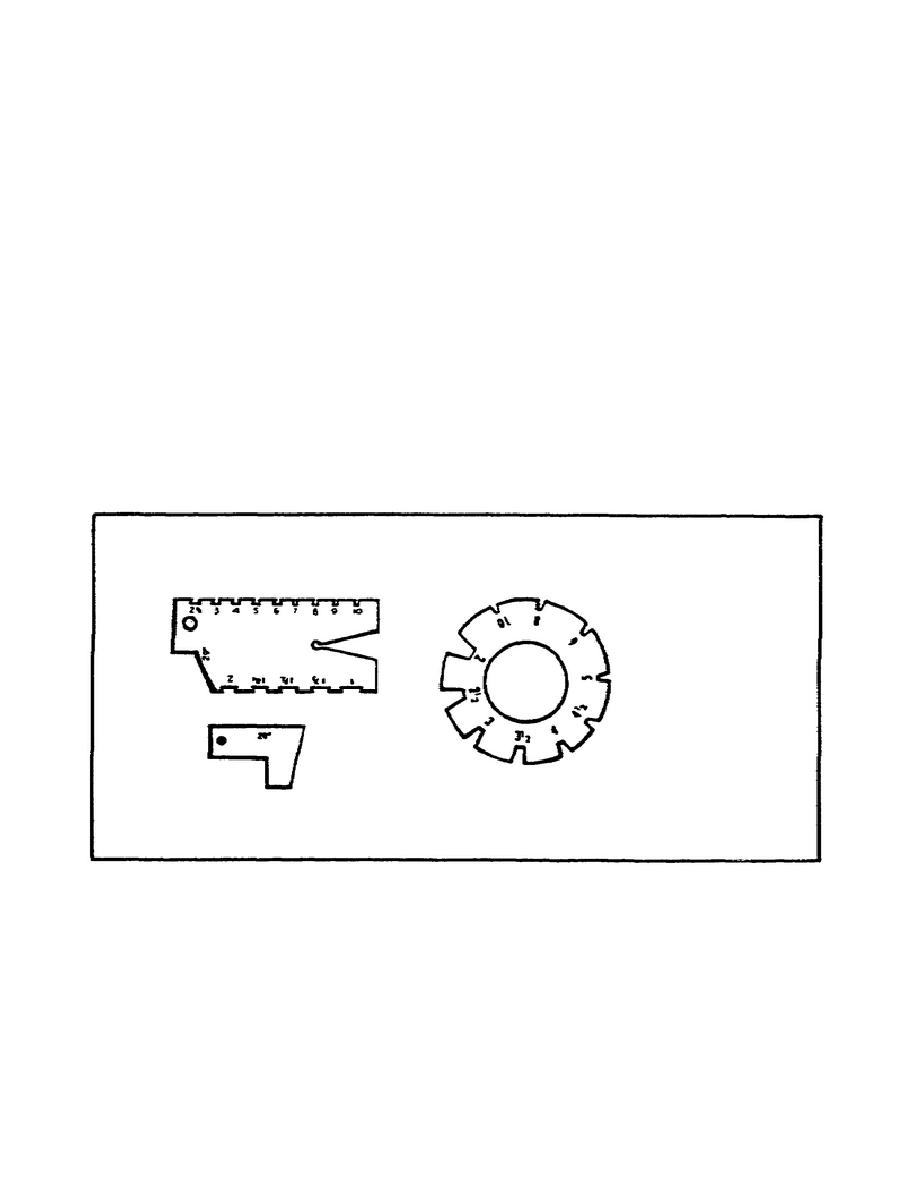

(3) Acme Thread Tool Gage. The Acme thread cutting gages (figure 19)

are hardened steel plates with cutouts around the perimeter. Each cutout is

marked with a number that represents the number of threads per inch. These

gages provide a standard for thread cutting tools that are being ground.

The tool is also used to align the Acme thread cutting tool prior to

machining them on a lathe. The sides of the Acme thread have an included

angle of 29 (14 1/2 on each side) and that is the angle made into the gage.

The width of the flat on the point of the tool varies according to the

number of threads per inch. The gage provides different slots to use as a

guide when grinding the tool. Setting the tool up in the lathe is simple.

First, ensure that the tool is centered to the work as far as the height is

concerned. Then, with a gage edge laid parallel to the centerline of the

work, adjust the side of the tool until it fits the angle on the gage very

closely.

FIGURE 19.

THREAD CUTTING TOOL GAGES.

(4) Center Gage. The center gage (figure 20 on the following page)

is used like the Acme thread gage. Each notch and the point of the gage has

an included angle of 60. The sixty-degree angles of

31

Previous Page

Previous Page