PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

bend or kink.

A good way to get the "feel" of using a thickness gage

correctly is to practice with the gage on openings of known measurements.

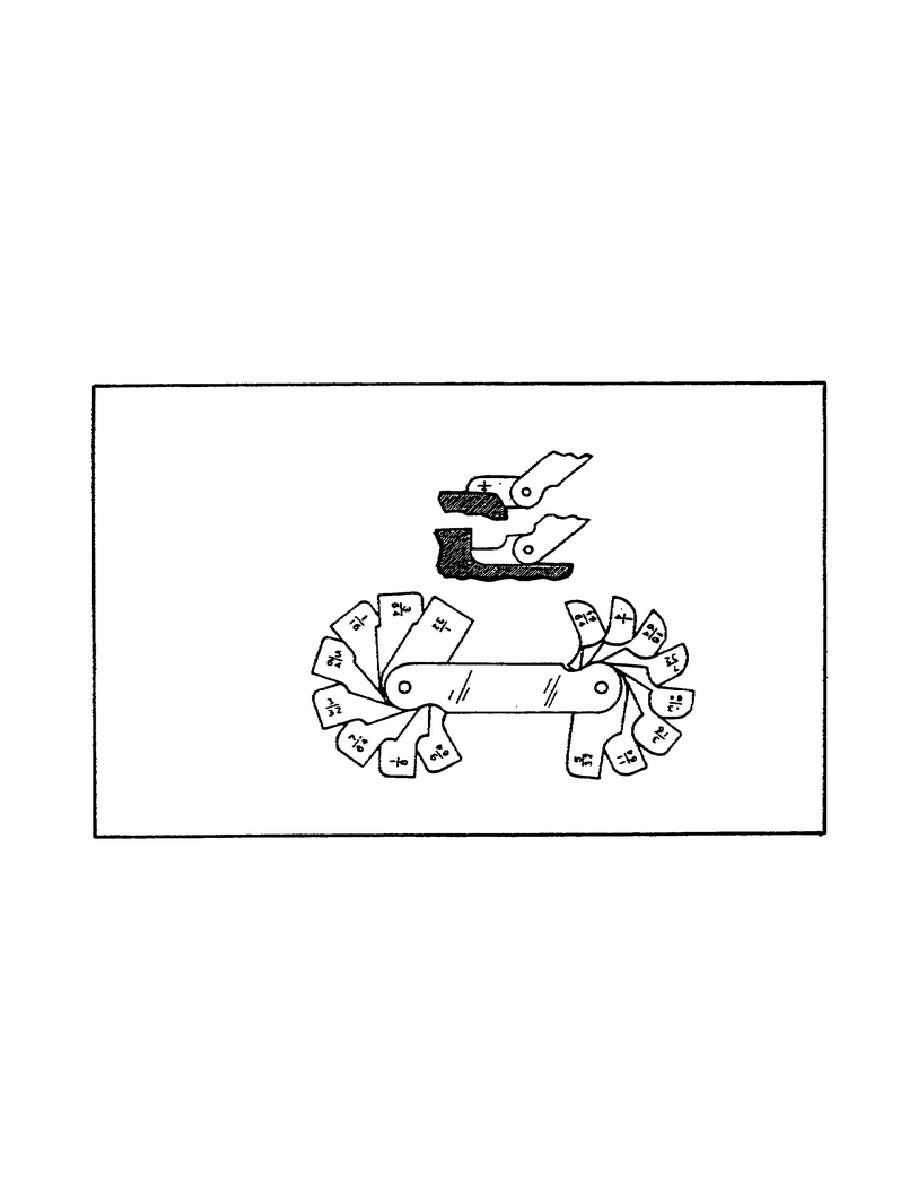

(6) Radius Gage.

(a) The radius gage (figure 22) is used to check, in any position

and at any angle, both inside and outside radii.

This gage is often

underrated in its usefulness to the machinist. The blades of the fillet and

radius gages are made of hard-rolled steel. The double-ended blades of the

gage have a lock which holds the blade in position. The inside and outside

radii are on one blade on the gage.

Each blade of the gage is marked in

64ths. Each gage has 16 blades.

FIGURE 22.

FILLET AND RADIUS GAGES.

(b) Whenever possible, the design of most parts includes a radius

located at the shoulder formed when a change is made in the diameter. This

radius gives the part an added margin of strength at that particular place.

When a square shoulder is machined in a place where a radius should have

been, the possibility that the part will fail by bending or cracking is

increased. The blades of most radius gages have both concave (inside curve)

34

Previous Page

Previous Page