PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

(9) Sine Bar.

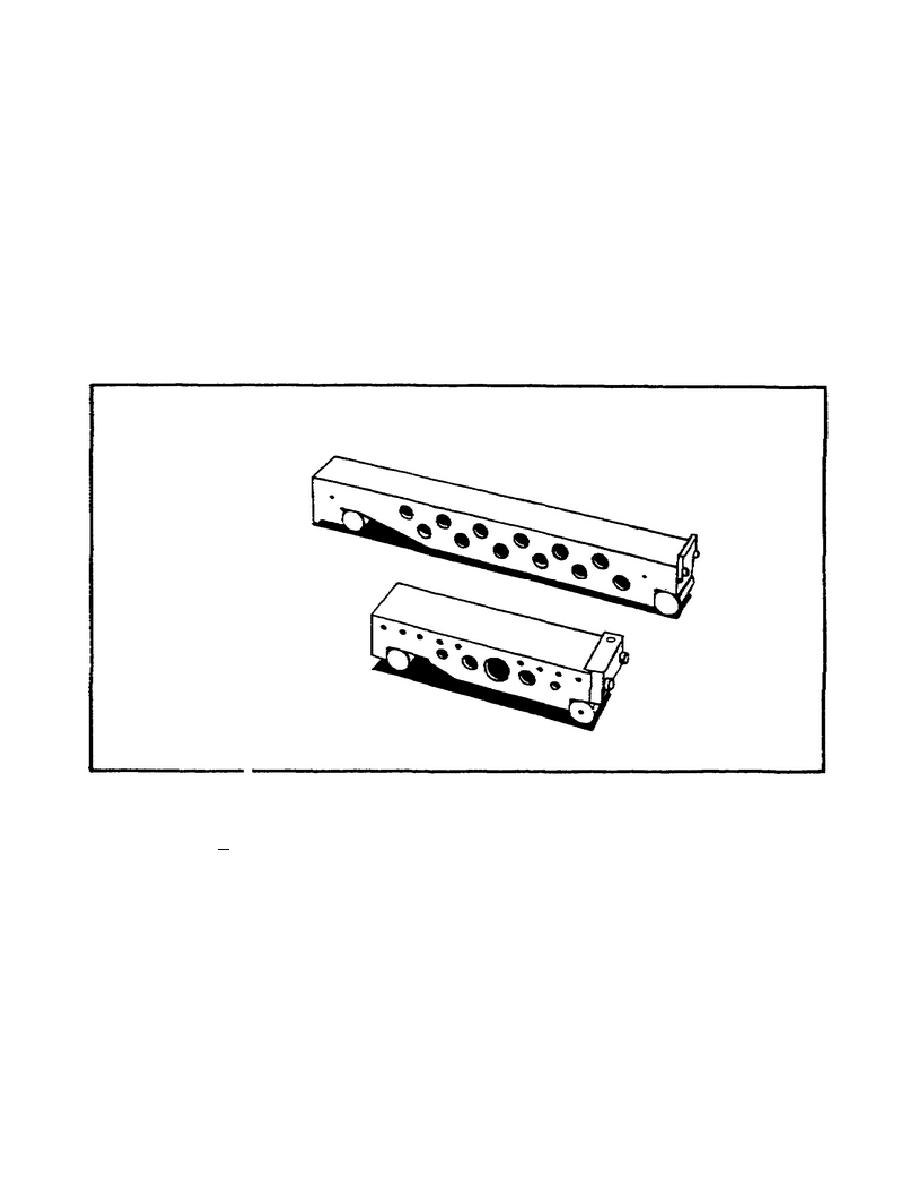

(a) General. A sine bar (figure 24) is a precision tool used to

establish angles which require extremely close accuracy.

When used in

conjunction with a surface plate and gage blocks, angles are accurate to

within 1 minute (1/60). The sine bar may be used to measure angles on a

workpiece and to lay out an angle on the workpiece that is to be machined.

Work may be mounted directly to the sine bar for machining. The cylindrical

rolls and the parallel bar, which make up the sine bar, are all precision

ground and accurately positioned to permit such close measurements.

Any

scratches, nicks, or other damage should be repaired before the sine bar is

used, and care must be exercised in using and storing the sine bar.

FIGURE 24.

SINE BARS.

(b) Use.

1 A sine bar is a precisely machined tool steel bar used in

conjunction with two steel cylinders. In the type shown in figure 25 on the

following page, the cylinders establish a precise distance of either 5

inches or 10 inches from the center of one to the center of the other,

depending upon the model used.

The bar itself has accurately machined

parallel sides. The axes of the two

36

Previous Page

Previous Page