PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

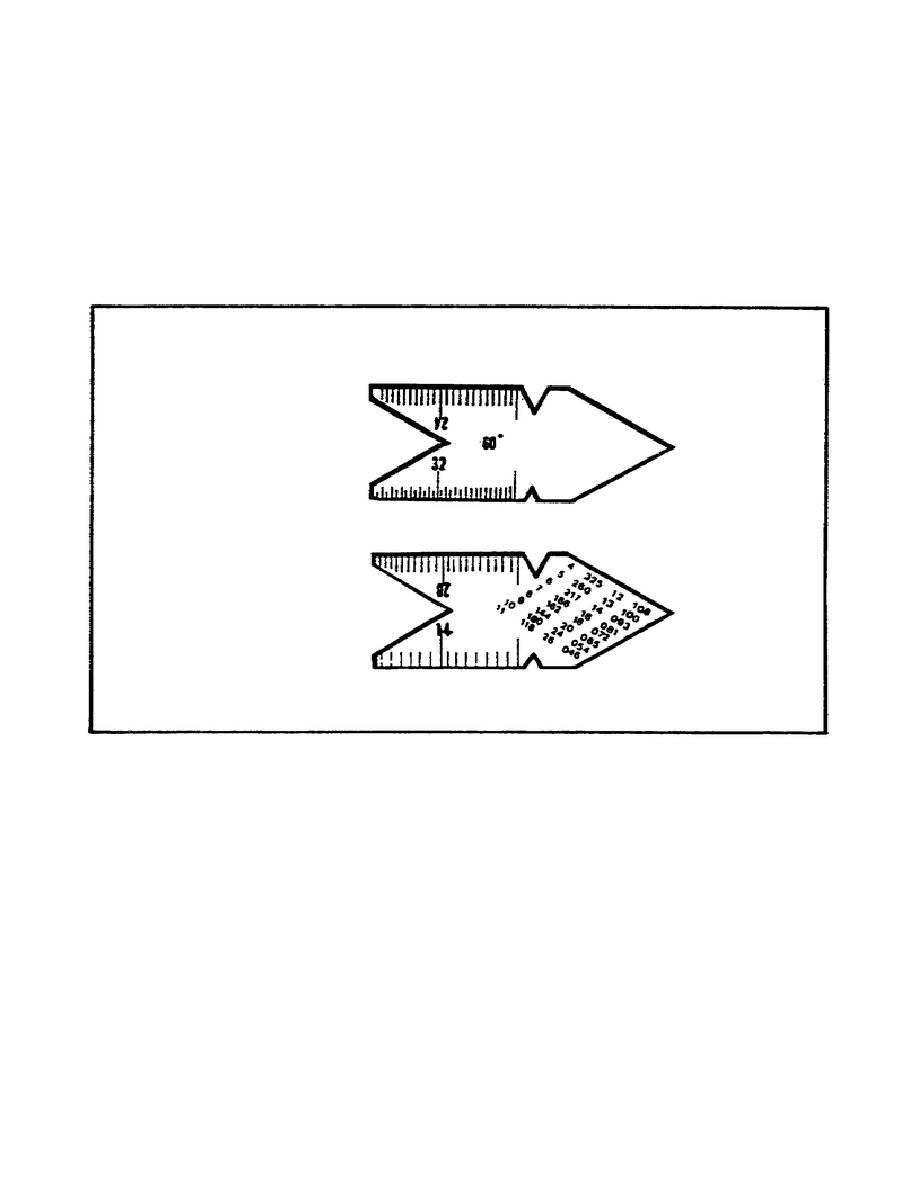

the gage are used for checking Unified and American threads, as well as

older American National or U.S. Standard threads, and for checking thread

cutting tools.

The center gage is also used to check the angle of lathe

centers. The edges are graduated into 1/4, 1/24, 1/32, and 1/64 of an inch

for ease in determining the pitch of threads on screws.

The back of the

center gage has a table giving the double depth of the threads in

thousandths of inch for each pitch.

This information is also useful in

determining the size of tap drills.

FIGURE 20.

CENTER GAGE.

(5) Thickness (Feeler) Gages.

(a) Thickness (feeler) gages (figure 21 on the following page) are

used to determine distances between two mating parts. The gages are made in

various shapes and sizes; usually 2 to 26 blades are grouped into one tool

and graduated in thousandths of an inch.

(b) Most thickness blades are straight, while others are bent at

the end at 45 degree and 90 degree angles. Some thickness gages are grouped

so that there are several short and several long blades together. Thickness

gages are also available in single blades and in strip form for specific

measurements.

32

Previous Page

Previous Page