PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

shaft-shaped bar that has a precisely ground diameter for checking inside

diameters or bores.

(12) Micrometer Standards.

Micrometer standards are either disk or

tubular shaped gages that are used to check outside micrometers for

accuracy. Standards are made in sizes so that any size micrometer can be

checked. They should be used on a micrometer on a regular basis to ensure

continued accuracy.

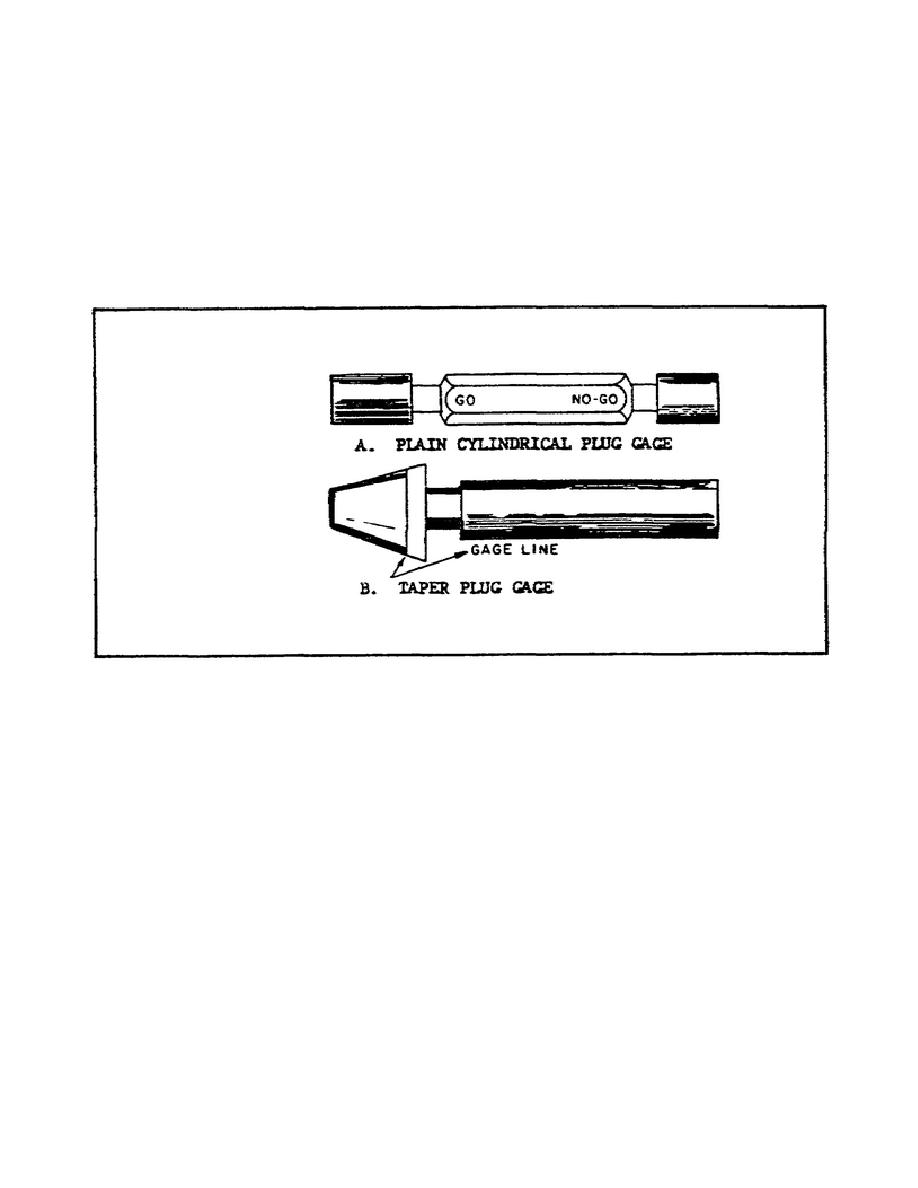

FIGURE 29.

PLUG GAGES.

(13) Gage Blocks.

(a) Gage blocks (figure 30 on the following page) are available in

sets from 5 to 85 blocks of different dimensions. Precision gage blocks are

made from a special alloy steel.

They are hardened, ground, and then

stabilized over a period of time to reduce subsequent waxing.

They are

rectangular in shape with measuring surfaces on opposite sides.

The

measuring surfaces are lapped and polished to an optical flat surface and

the distance between them is the measuring dimension.

The dimension may

range from 0.010 of an inch up to 20 inches.

(b) Gage blocks are used as master gages to set and check other

gages and instruments. They are accurate from eight millionths (0.000008)

of an inch to two millionths (0.000002) of an inch, depending on the grade

of the set. To visualize this minute amount, consider that the thickness of

42

Previous Page

Previous Page