PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

(j) Gage

blocks

are

commonly

used

in

setting

adjustable

instruments and indicating gages and verifying inspection gages.

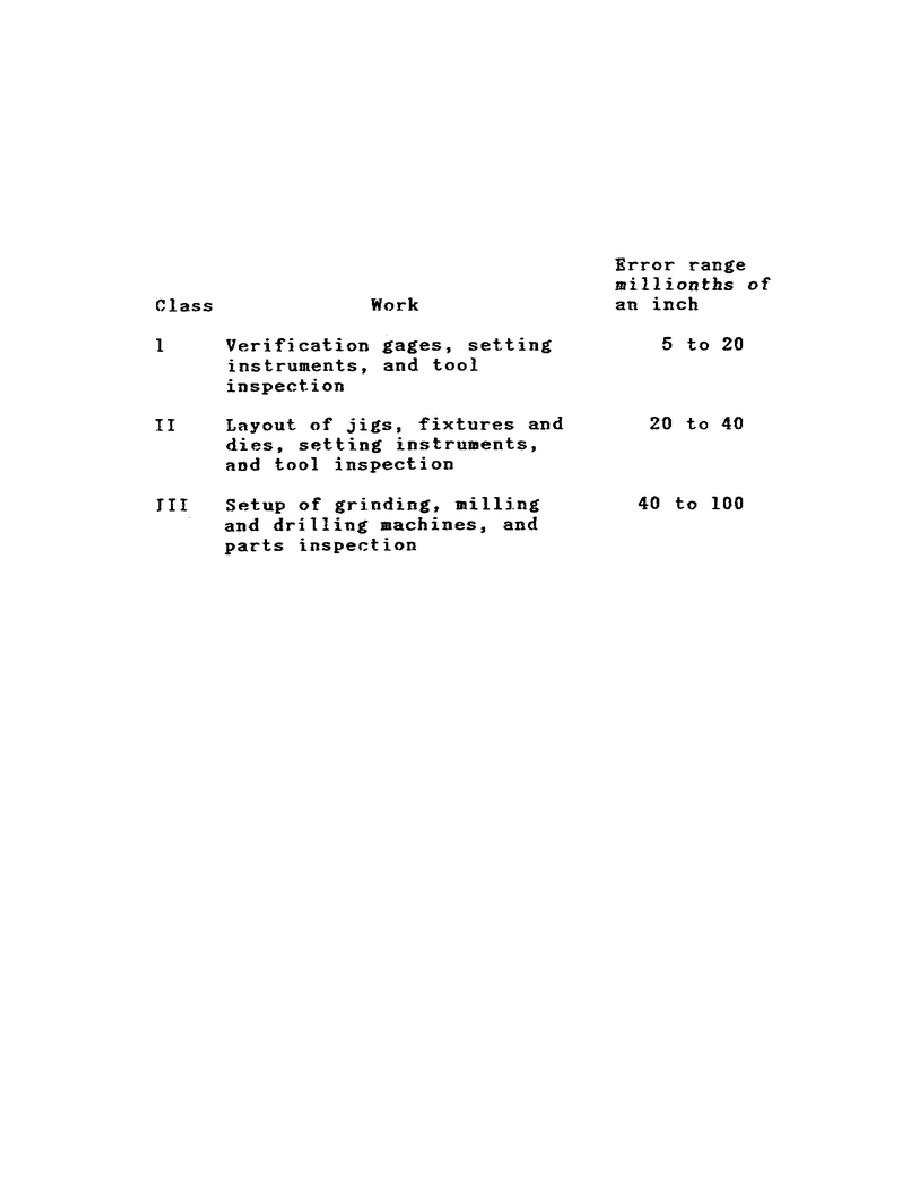

Gage

blocks are used to verify the accuracy of ring and snap gages and many other

special-purpose gages. The classification of blocks depends largely on the

accuracy required. Typical classification is as follows:

(14) Care.

The following steps should be followed when caring for

precision gage blocks:

Step 1. Observe particular care when using gage blocks to measure hardened

work. The danger of scratching is increased when the work is as hard as the

block, or harder.

Step 2.

Never touch the measuring surfaces of the blocks any more than

necessary.

The moisture from one's hands contains acid which, if not

removed, will eventually stain the blocks.

Step 3. Before using the gage blocks, ensure that there is no grease, oil,

dirt, or other foreign substances on the block.

Step 4. Every time a set of blocks is used, all of the blocks which have

been cleaned for use must be covered with a light film of acid-free oil,

such as boiled petroleum, before they are put away. Wipe them with an oiled

chamois as the blocks are returned back to their places in the case.

47

Previous Page

Previous Page