PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

them, the pitch diameter of the threads can be determined.

Sets are

available that contain all the more common sizes. Detailed information on

computing and using the wire method is covered in most machinist and

technical manuals.

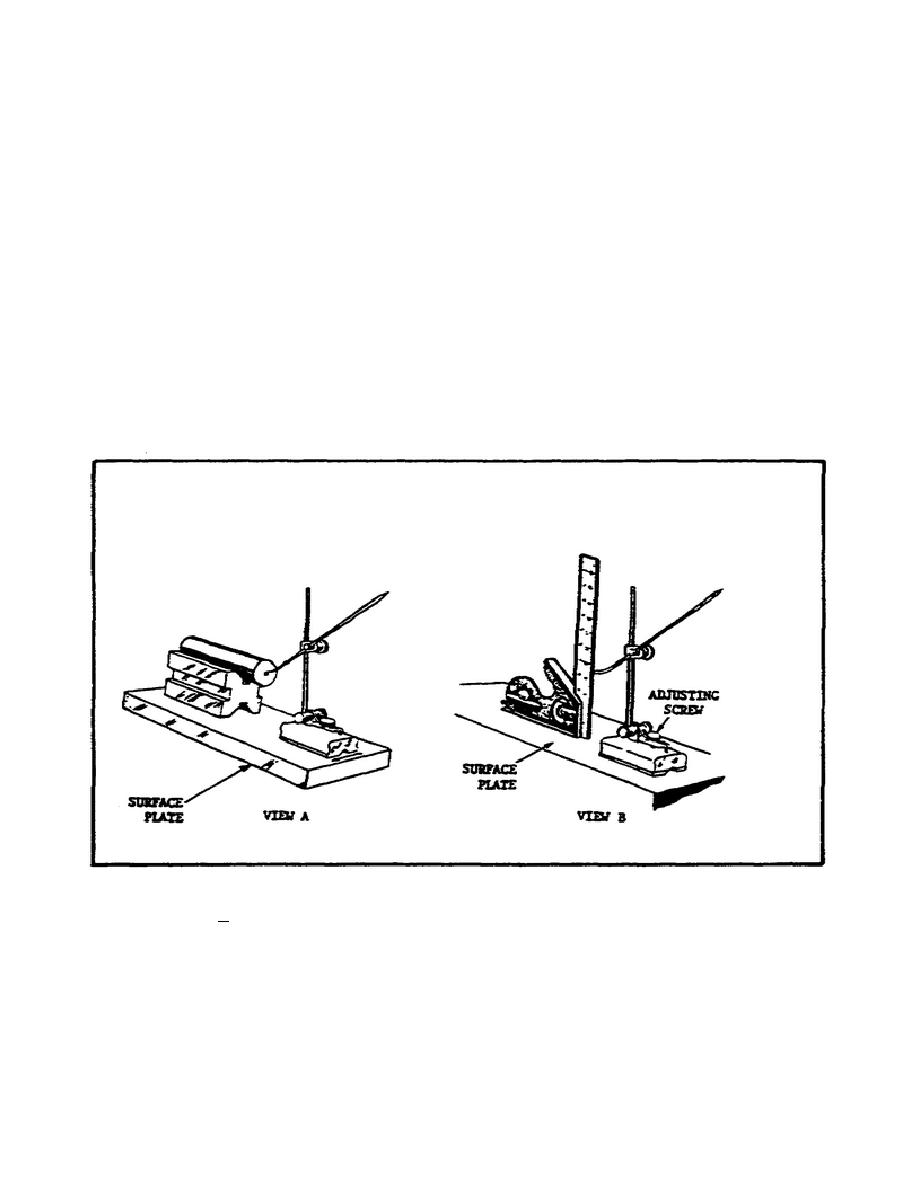

(17) Surface Plate.

(a) General. A surface plate (figure 32) provides a true, smooth,

plane surface.

It is often used as a level base for surface and height

gages from which to make accurate measurements. Surface plates are usually

made of close grain cast iron, are rectangular in shape, and come in a

variety of sizes.

(b) Uses. The surface plate is used with such tools as parallels,

squares, surface gages, angle plates, and sine bar in making layout lines.

Angle plates are used to mount work at an angle on the surface plate.

FIGURE 32.

SETTING A SURFACE GAGE ON THE SURFACE PLATE.

1 View A of figure 32 shows a surface gage and a V-block

combination used in laying out a piece of stock. To set the surface gage

for height, first clean the top of the surface plate and the bottom of the

surface gage.

Then, place the squaring head of a combination square is

shown in view B of figure 32. The scale is secured in

49

Previous Page

Previous Page