There are some preliminary troubleshooting procedures that you must accomplish

prior to troubleshooting the conveyor assembly:

o Ensure the vehicle MASTER switch is in the ON position.

o Ensure the APU is operating the primary hydraulic pump and the hydraulic

system selector valve is pushed IN, or the main engine is operating the

backup hydraulic pump and the hydraulic system selector valve is pulled OUT.

WARNING

Test components must be capable of withstanding a working

pressure of 2000 psi. Also, NEVER tighten hydraulic lines

or fittings while the hydraulic system is pressurized.

Damage to tubes and fitting could result in personal

injury.

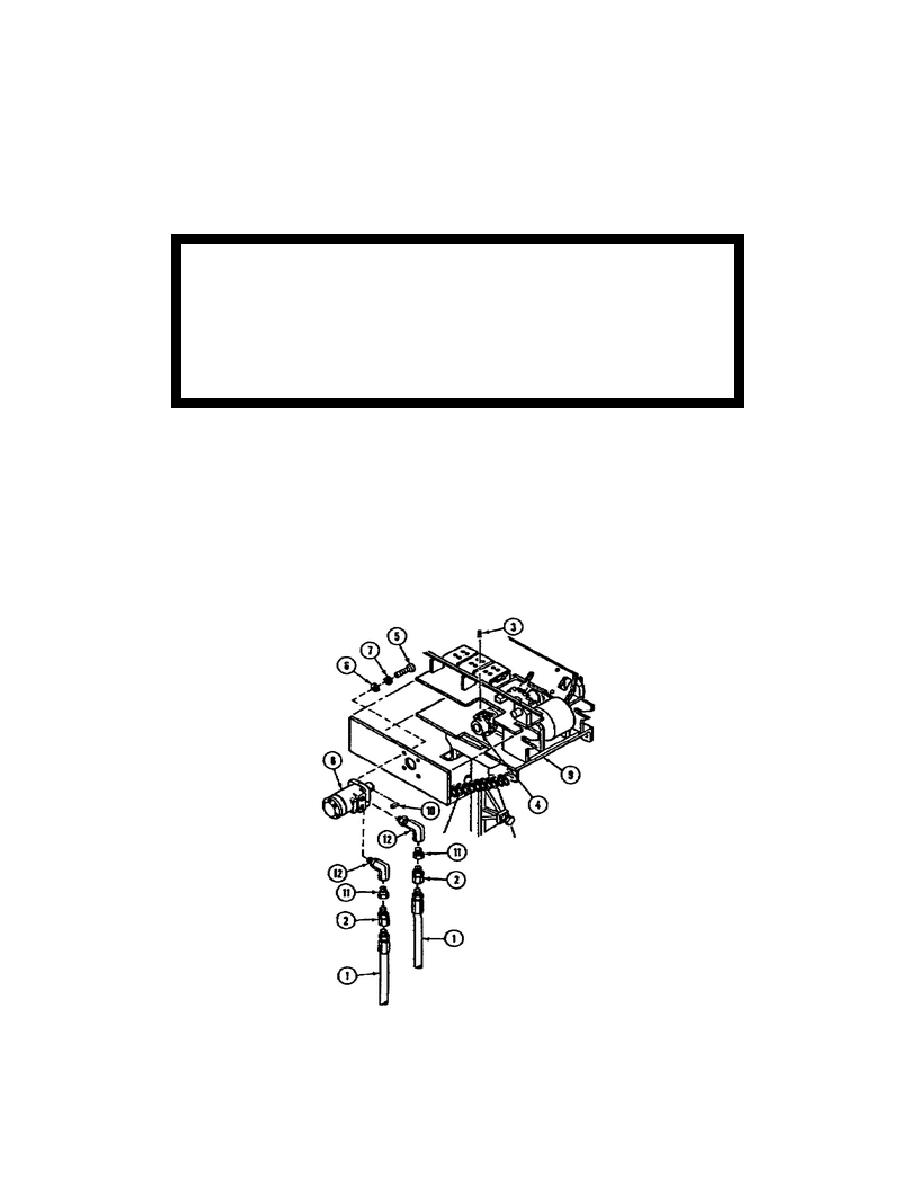

o Check the hydraulic panel pressure gage.

The gage should indicate between

100 and 300 psi (Fig. 27). If the pressure gage is not in the correct range,

you must troubleshoot the primary hydraulic system.

o Ensure the conveyor is fully deployed (TM 9-2350-267-10).

o Ensure the conveyor override safety switch is in the ON position.

o Check the flow control valve. If the flow control valve is closed, open the

valve and adjust the conveyor speed (Fig. 27).

Figure 27.

Hydraulic Control Panel.

34

OD1737

Previous Page

Previous Page