PART C - OPERATION OF THE HYDRAULIC

SYSTEM UNDER EMERGENCY CONDITIONS

1.

Hydraulic Power Loss (Primary Hydraulic Pump Failure).

If the primary hydraulic pump fails, switch to the backup hydraulic pump

using the following procedures, and notify organizational maintenance.

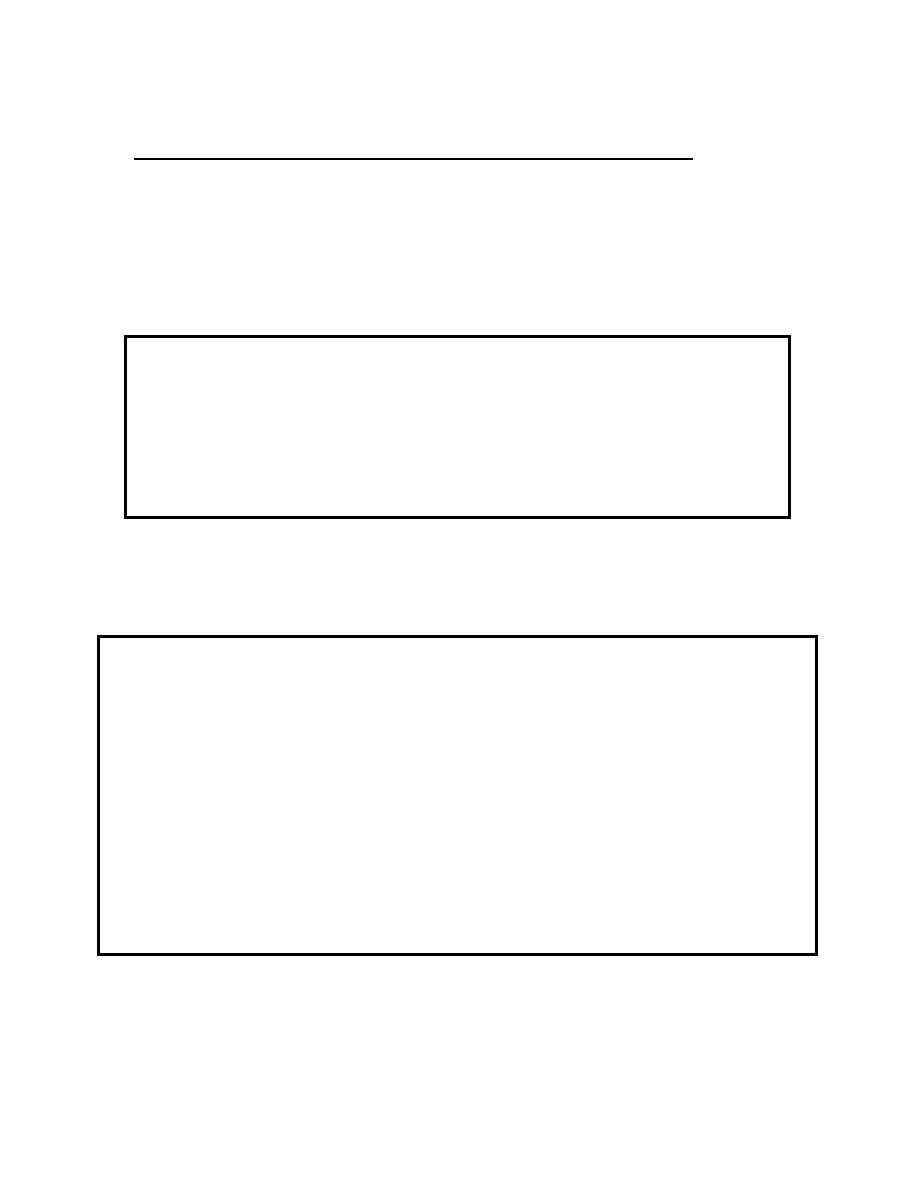

o Pull the hydraulic system selector valve handle out (Fig. 3F).

o Close the backup system

dump

valve

by

turning

the

handle

clockwise (Fig. 3F).

CAUTION

Do not allow hand pump pressure to exceed 150 psi. Excessive

pressure will damage hydraulic components.

If pressure

exceeds 150 psi, IMMEDIATELY open dump valve (by turning

handle counterclockwise) until the reading drops below 150

psi. Then close dump valve by turning handle fully clockwise.

o Manually operate the handle of the manual hydraulic pump until

the hand pump pressure gage indicates pressure is between 125 and

150 psi. This will engage the backup hydraulic pump to the main

engine (Fig. 3F).

CAUTION

o Be sure that the hydraulic ball valve is OPEN before starting

the main engine with the backup pump engaged.

o Serious damage to the hydraulic components will result if you

do not take this action.

o Do not move the vehicle with the backup pump engaged; damage

to the backup pump will result.

o When operating the backup hydraulic pump, do no allow the main

engine to exceed 1100 RPM; damage to the backup pump will

result.

13

OD1703

Previous Page

Previous Page