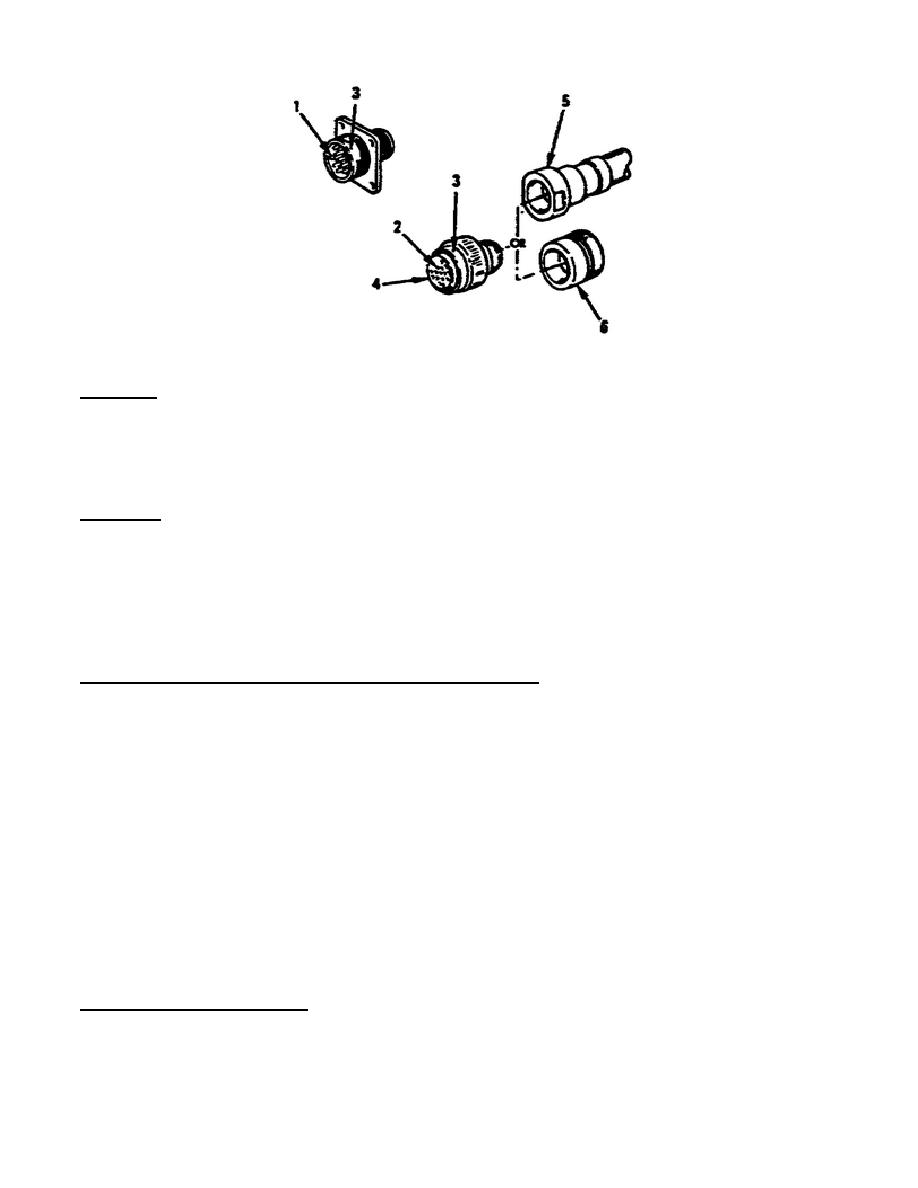

Figure 1-14.

Connector Inspection.

Block 9. Since you have found no faulty connector parts, go to block

9.

Following the instructions in this block, you connect the loose

connector and test the tank again.

If the transmission operates

correctly, you have found and corrected the problem with the

transmission, a loose connector.

Block 8.

If you find faulty connector parts, follow the YES flow

line of the fault isolation chart to block 8.

Following the

instructions in this block, you replace the faulty wire harness, or

in the case of the wire harness you inspected for this lesson (2W105-

9), notify support maintenance, and test the tank again. If the wire

harness was the only fault, you have found and corrected the problem

with the transmission.

Troubleshooting Using the STE Test Set.

For this lesson, you

continue to troubleshoot the transmission.

Look at block 5 of the

fault isolation chart again. The final question asks if a connector

is loose.

This time, you follow the NO flow line of the fault

isolation chart to block 7, which then directs you to block 18, "get

STE test set." Since you have ruled out any loose connectors, you are

ready to troubleshoot using the STE.

Also look at block 9 again. This block asks if the tank moved when

you tested it.

This time you follow the NO flow line to block 10,

which also directs you to block 18, "get STE test set." Since you

have replaced any wire harnesses containing faulty connectors and

tightened any loose connectors, and the tank still does not pivot,

you are ready to troubleshoot using the STE.

Thus blocks 7 and 10

bring you to the same troubleshooting step (block 18).

Block 18 to Block 20.

Block 18 asks if you have the STE test set.

For this part of the lesson, follow the YES flow line to block 20,

and continue to troubleshoot using the STE test

22

OD1711

Previous Page

Previous Page