connectors and their locations; a loose connector could cause the

symptom you have to troubleshoot.

For this lesson, when you

inspected the 2W105-9/P4 connector, you found it loose.

Following

the note in the block, you immediately go to block 6.

Block 6. Block 6 instructs you to perform a connector inspection and

asks the question, "Are any connector parts faulty?" after you have

completed the inspection. Each time you find a loose connector, you

must perform a connector inspection using the following steps:

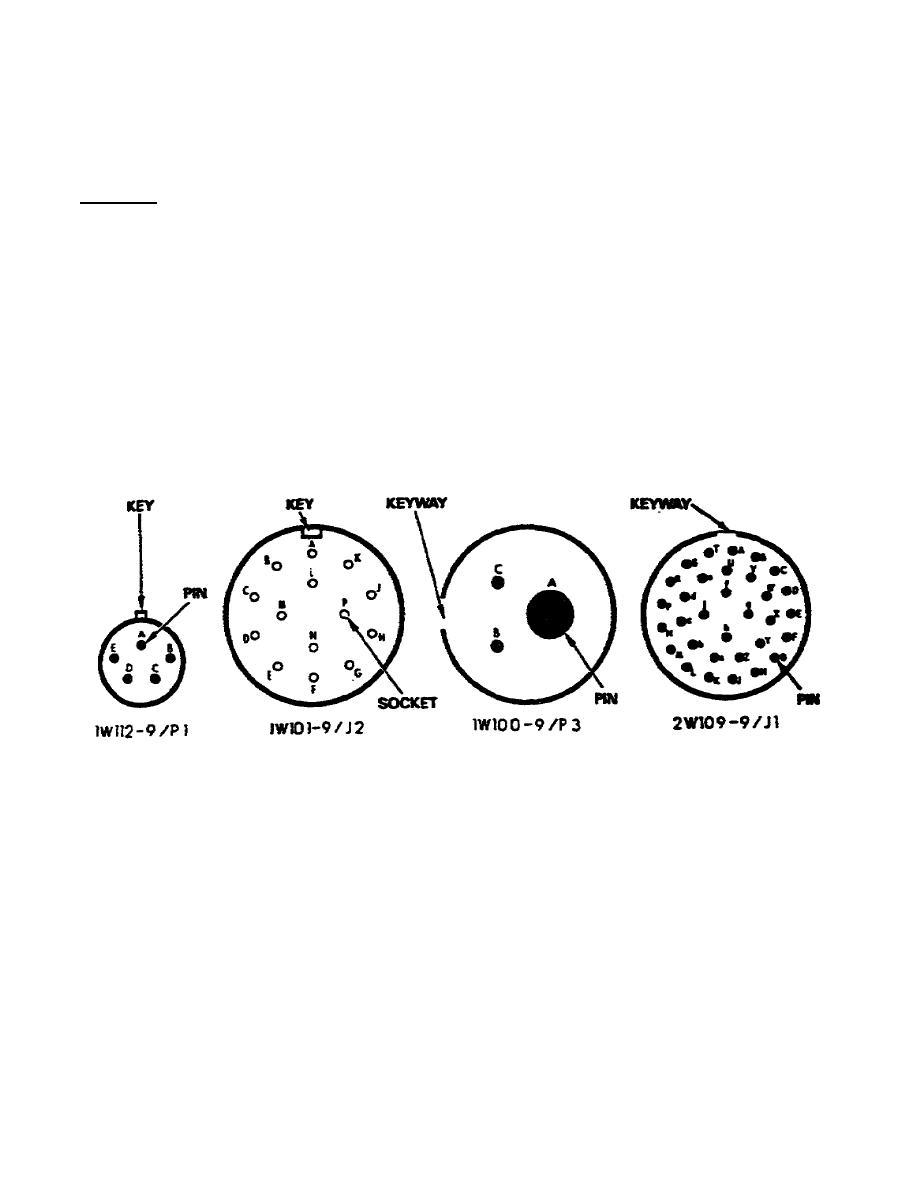

Connector identification.

The troubleshooting illustrations

have connector diagrams giving the location of each pin or

socket in relation to the main key or keyway on the connector.

Figure 1-13 shows typical connectors with views of mating

faces rotated, when necessary, to show all lettering in an

upright position.

The connectors you work with may look

different; however, they have similar parts.

To identify

specific connectors using the wiring harness number, refer to

TM 9-2350-264 -20-1.

Figure 1-13.

Typical Connectors.

Connector inspection. Begin the connector inspection process

by checking the pins (1) and sockets (2) for dirt and

corrosion (fig. 1-14). If you find dirt or corrosion, clean

the connector using the general maintenance instructions found

in TM 9-2350-264-20-1.

Then, check the connector body (3),

insert (4), adapter (5), and shell (6) for dents or breaks.

Additionally, inspect the insert for missing sockets (2) and

the connector body for missing, bent or broken pins (1)(fig.

1-14).

If you find faulty connector parts, notify your

supervisor.

If you do not find faulty parts, continue

troubleshooting.

21

OD1711

Previous Page

Previous Page