(3) Hoses are provided with connections at each end so that they may be

connected to their respective regulator outlet and torch inlet connections. To

prevent a dangerous interchange of acetylene and oxygen hoses, all threaded

fittings used for the acetylene hookup are left hand and all threaded fittings for

the oxygen hookup are right hand.

(4) Welding and cutting hose is obtainable as a single hose for each gas or

with the hoses bonded together along their length under a common outer rubber

jacket. This type prevents the hose from kinking or becoming entangled during the

welding operation.

e. Oxyacetylene welding torch.

(1) The oxyacetylene welding torch is used to mix oxygen and acetylene in

definite proportions and to control the volume of these gases burning at the

welding tip. The torch has two needle-type valves: one for adjusting the flow of

oxygen and one for adjusting the flow of acetylene. In addition, there are two

tubes, one for oxygen, the other for acetylene; a mixing head; inlet nipples for

the attachment of hoses; a tip; and a handle. The tubes and handle are of seamless

hard brass, copper nickel alloy, stainless steel, or other noncorrosive metal of

adequate strength.

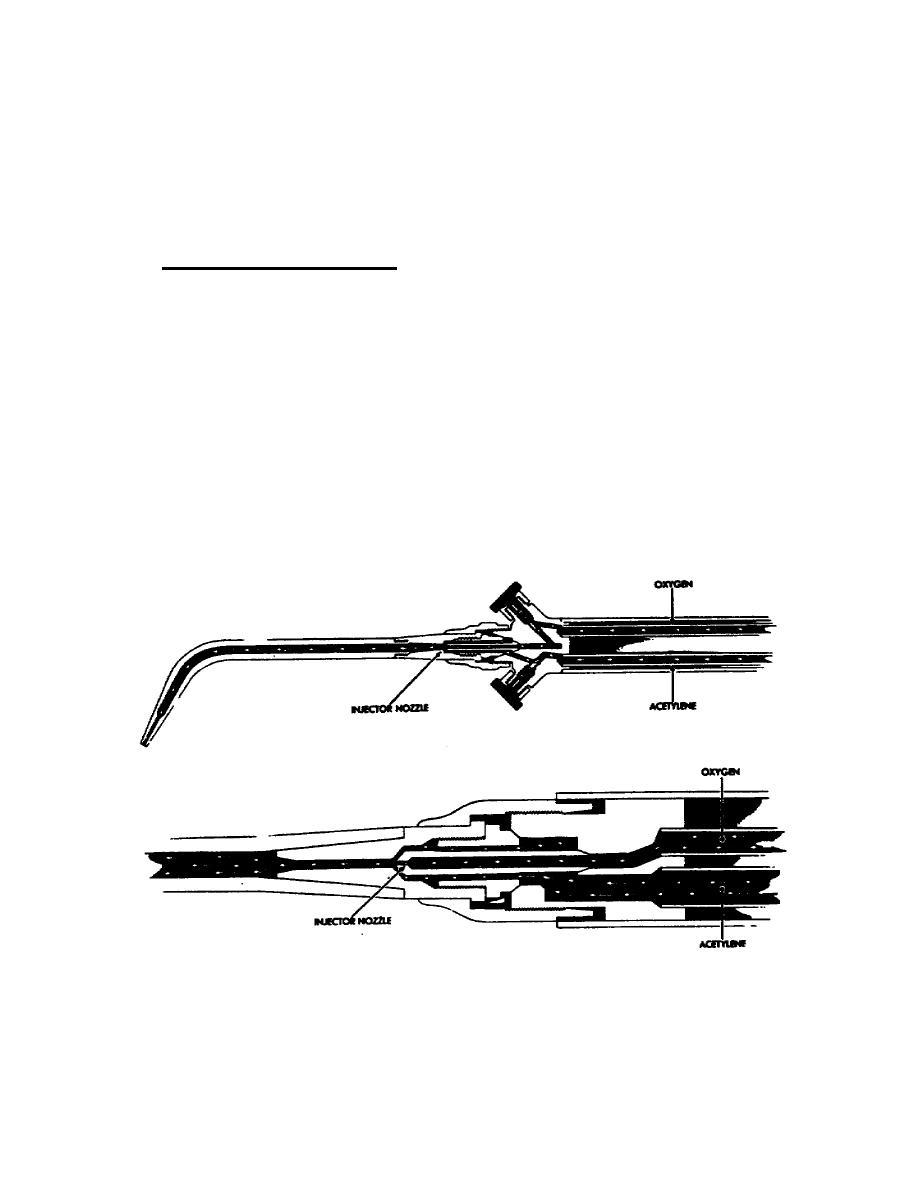

(2) There are two general types of welding torches: the low-pressure or

injector type and equal pressure type.

(a) In the low-pressure or injector type (fig 6) the acetylene pressure

is less than 1 PSI. A jet of high-pressure oxygen is used to produce a suction

effect to draw in the required amount of acetylene. This is accomplished by

designing the mixer in the torch to operate on the injector principle. The welding

tips may or may not have separate injectors designed integrally with each tip.

Figure 6.

Mixing head for injector type welding torch.

111

Previous Page

Previous Page