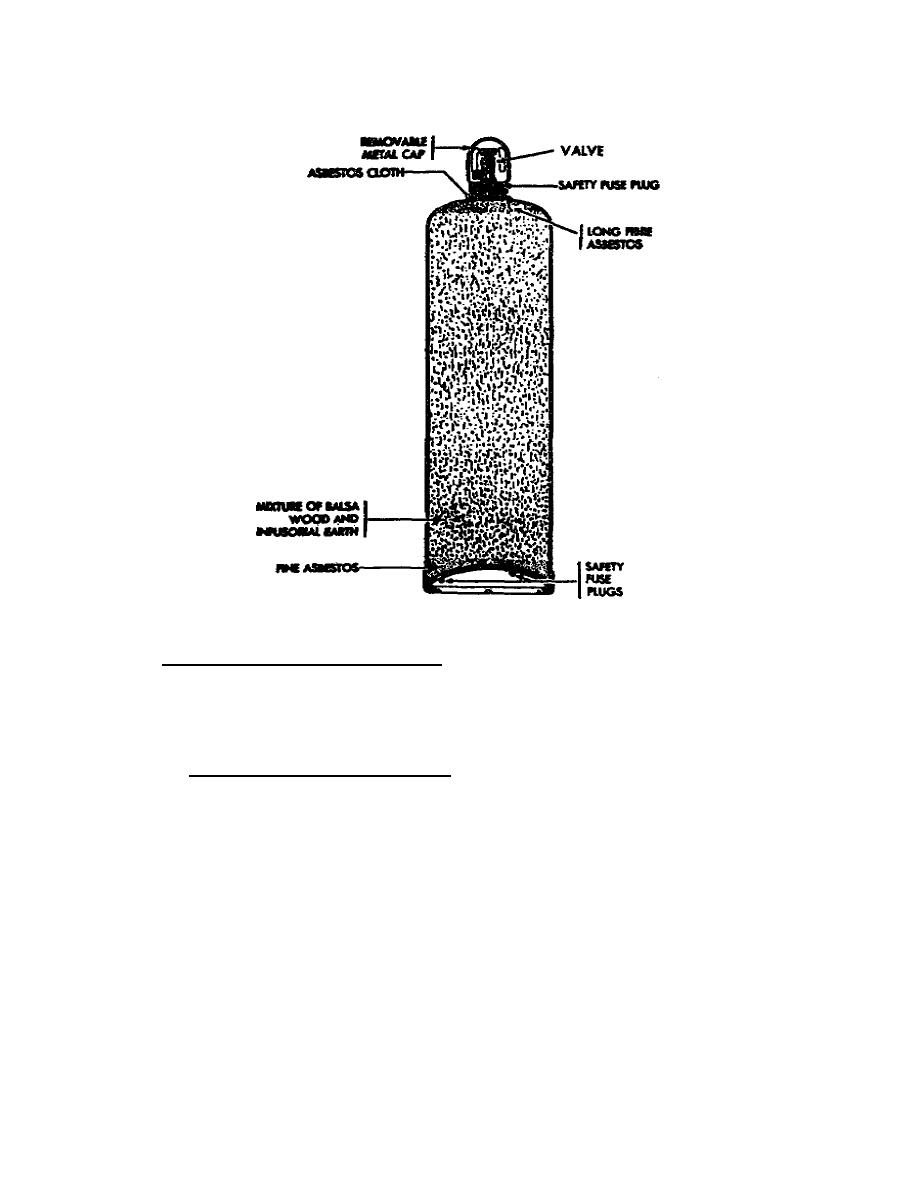

Figure 4.

Acetylene cylinder construction.

c. Oxygen and acetylene regulators. The gases compressed in oxygen and

acetylene cylinders are at pressures too high for oxyacetylene welding. Regulators

are necessary to reduce pressure and control the flow of gases from the cylinders.

Most regulators in use are either the single-stage or the two-stage type. Check

valves should be installed between the torch hoses and regulator to prevent

backflash through the regulator.

(1) Single-stage oxygen regulator. The mechanism of a single-stage

regulator (fig 5) has a nozzle through which the high-pressure gas passes, a valve

seat to close off the nozzle, and balancing springs. Some types have a relief

valve and an inlet filter to exclude dust and dirt. Pressure gages are provided to

show the pressure in the cylinder or pipeline and the working pressure. In

operation, the working pressure falls as the cylinder pressure falls; for this

reason, the working pressure must be adjusted at intervals during welding

operations. The oxygen regulator controls and reduces the oxygen pressure from any

standard commercial oxygen cylinder containing pressures up to 3,000 PSI. The

high-pressure gage, which is on the inlet side of the regulator, is graduated from

0 to 3,000 PSI. The low-pressure gage, which is on the outlet side of the

regulator, is graduated from 0 to 500 PSI.

108

Previous Page

Previous Page