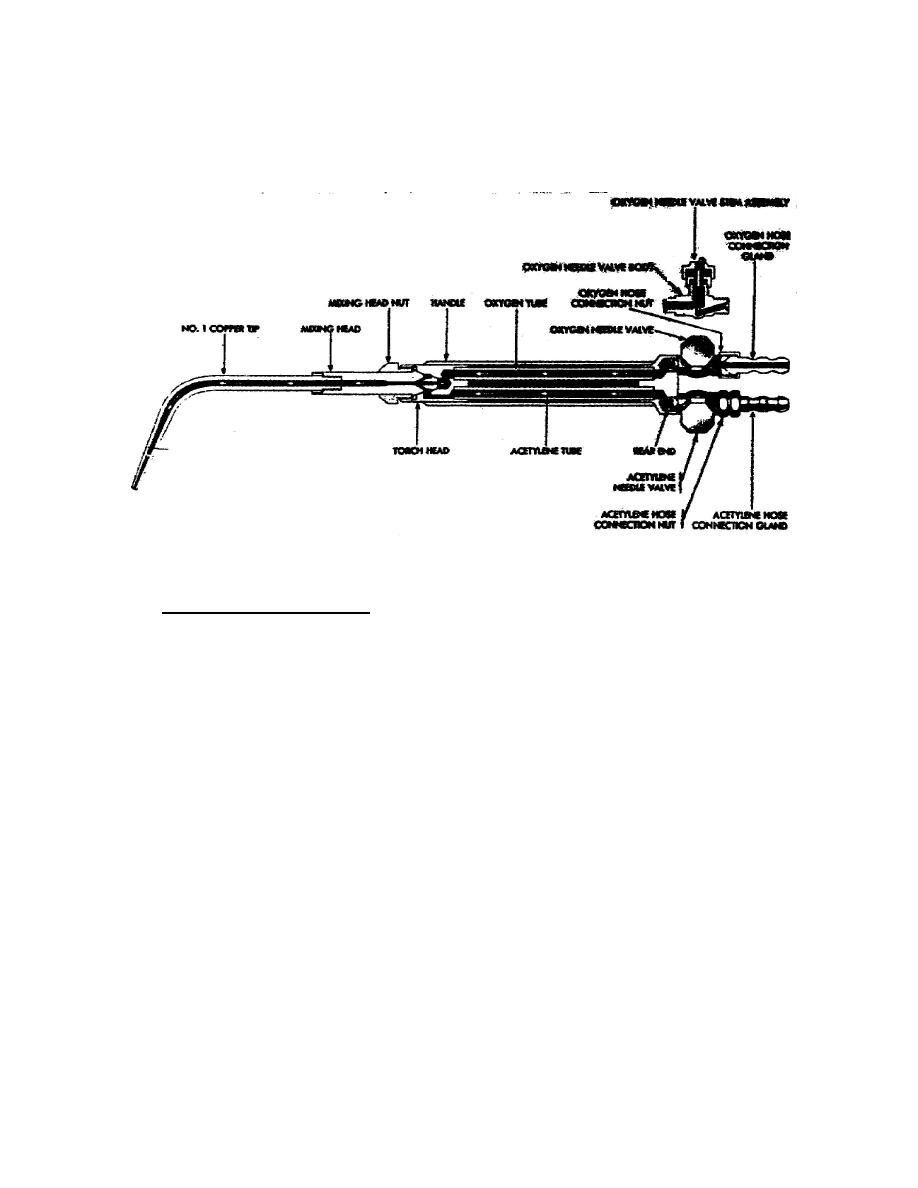

(b) The equal pressure torch (fig 7) is designed to operate with equal

pressures for the oxygen and acetylene. The pressure ranges from 1 to 15 PSI.

This torch has certain advantages over the low-pressure type in that the flame

desired can be more readily adjusted and, since equal pressures are used for each

gas, the torch is less susceptible to flashbacks.

Figure 7.

Equal pressure type, general purpose welding torch.

f. Welding tips and mixers.

(1) The welding tips (fig 6 and 7) are made of hard drawn electrolytic

copper or 95 percent copper and 5 percent tellurium. They are made in various

styles and types, some having a one-piece tip either with a single orifice or a

number of orifices, and others with two or more tips attached to one mixing head.

The diameters of the tip orifices differ in order to control the quantity of heat

and type of flame. These tip sizes are designated by numbers which are arranged

according to the individual manufacturer's system. In general, the smaller the

number, the smaller the tip orifice.

(2) Mixers (fig 7) are frequently provided in tip mixer assemblies which

assure the correct flow of mixed gases for each size tip. In this tip mixer

assembly the mixer is assembled with the tip for which it has been drilled and then

screwed onto the torch head. The universal type mixer is a separate unit which can

be used with tips of various sizes.

12. SETTING UP WELDING EQUIPMENT. When setting up welding equipment it is

important that all operations be performed systematically in order to avoid

mistakes and possible trouble. The setting up procedures given below will assure

safety to operator and the equipment.

112

Previous Page

Previous Page