f. Attaching the hose. Both oxygen and acetylene hose lines are now attached

to regulator outlet nipples. The oxygen hose (green) has right-hand threads and

acetylene hose (red) has left-hand threads on their respective connecting nipples.

This prevents their being interchanged with each other. Both are clearly marked to

eliminate confusion.

g. Blowing out the hose. No dirt or grit should be allowed to remain in the

hose which could be blown into the torch where it could obstruct the flow of gases.

Therefore, before attaching the torch, each hose should be blown out after being

attached to the regulator. Keep open flame away while this operation is being

performed. The ideal way to do this would be to blow the hoses out with compressed

air before attaching the hoses to either the regulator or torch. In the absence of

a compressed air supply, the above should be followed, observing. caution to avoid

accidental ignition of the gases.

h. Attaching the torch handle. The hoses are then screwed onto the torch

handle inlet connections. Make certain they are tight. The oxygen hose is

attached to right-hand threaded nipple (often marked OX) and the acetylene hose is

attached to the left-hand threaded nipple (often marked AC).

i. Blowing out the torch handle. Turn both adjusting screws to the right

until gas flows into the hoses. Open one valve on the torch at a time, blowing out

any dirt or grit that might have accumulated in the torch handle. Close the valves

quickly to prevent further escaping of the gases.

j. Attaching the tip. Select the proper size tip for the operation to be

performed and secure it in place in the torch handle.

k. Testing for leaks. When the equipment is completely set up and the

regulator adjusting screws are set for the correct operating pressures, it must be

certain that all gas connections are "GASTIGHT". This is assured by testing each

joint with a brush and soapy water. Any escaping gas will immediately produce a

soap bubble.

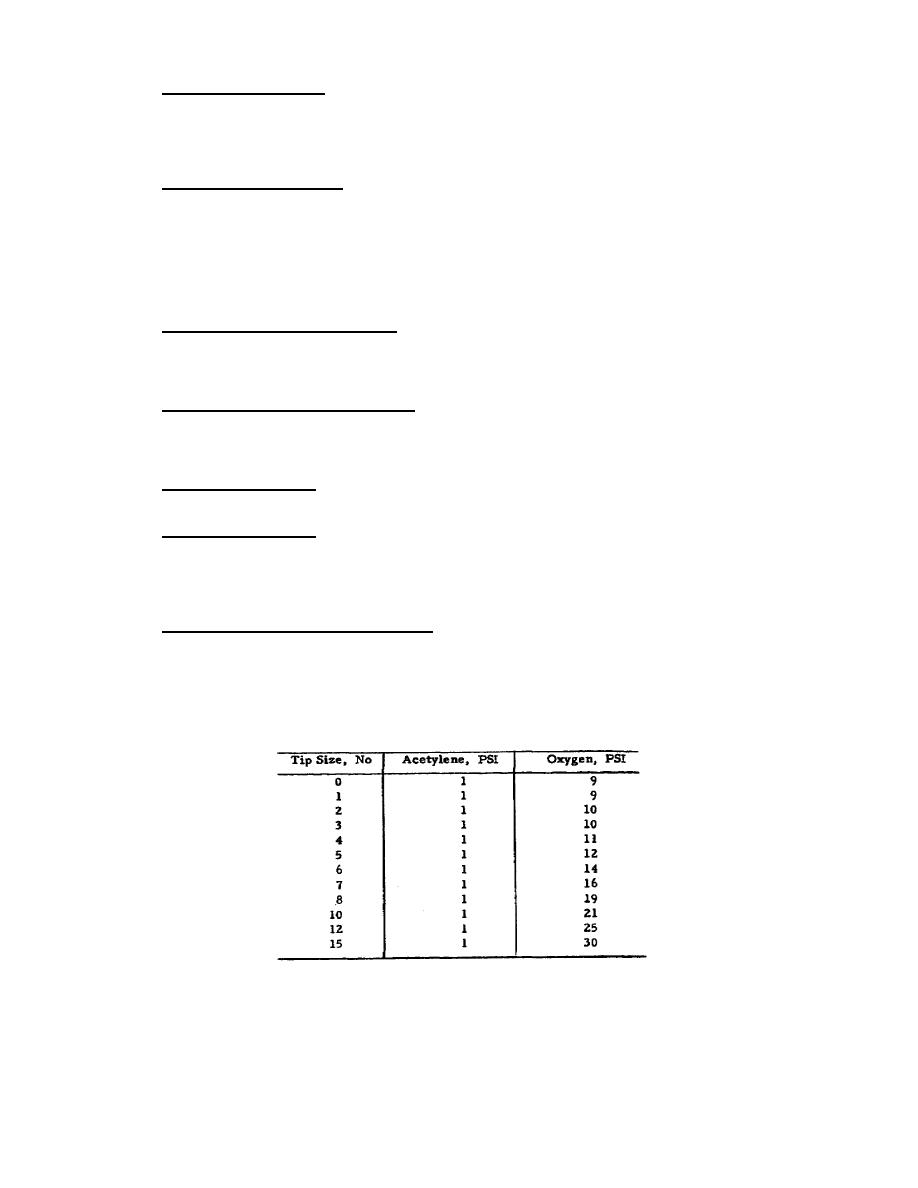

l. Adjustment of working pressure. Adjust the acetylene working pressure by

opening the acetylene needle valve in the torch and turning the regulator screw to

the right; then adjust the acetylene regulator to the required pressure for the tip

size to be used. Figures 9 and 10 provide pressure settings for a low-pressure or

injector type torch and a balanced pressure type torch. Close the needle valve.

Adjust the oxygen working pressure in the same manner.

Figure 9.

Low pressure or injector type torch.

114

Previous Page

Previous Page