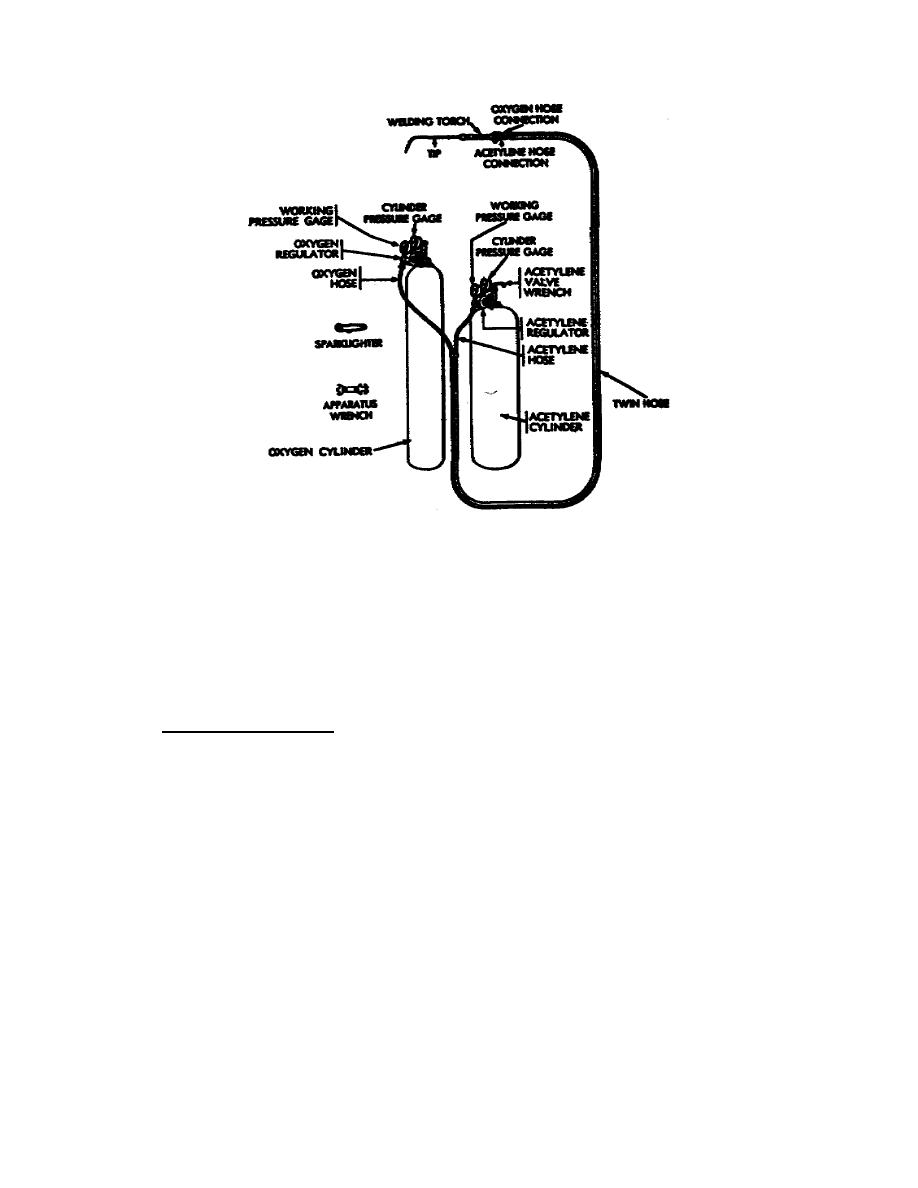

Figure 2,.

Portable oxyacetylene welding equipment,

(4) The oxygen cylinder valve is made of tobin bronze which is a soft

metal. A steel cap threaded to the top of the cylinder covers this valve and

protects it during transportation and storage. The valve has a double seat; the

second seat serving to prevent leakage around the valve stem when the valve is

fully opened. A bursting disk, held in place by a nut, is supported in the nut by

fusible metal that will melt at approximately 212F to 220F. This disk will

burst, releasing the gas, to prevent development of abnormal pressure in case of

fire. Valves have a handwheel on the stem and when in use the valve should be

opened as far as it will go. An oxygen cylinder is shown in figure 3.

(1) Acetylene, when not obtained from an acetylene generator, is provided

for welding purposes in steel cylinders with capacities of 10, 40, 125, and 225

cubic feet.

(2) Acetylene stored in a free state under pressure greater than 15 PSI can

be made to break down by heat or shock and possibly explode. Under pressure of

29.4 PSI acetylene becomes self-explosive and a slight shock will cause it to

explode spontaneously. However, when dissolved in acetone it can be compressed

into cylinders at pressures up to 250 PSI. The acetylene cylinder is filled with

porous materials such as balsa wood, charcoal, shredded asbestos, corn pith, or

portland cement in order to decrease the size of the open spaces in the cylinder.

Acetone, a colorless, flammable liquid, is added until about 40 percent of the

porous material is filled. The filler acts as a large sponge which absorbs the

acetone, which, in turn, absorbs the acetylene. In this process the volume of the

acetone increases as it absorbs the acetylene; while acetylene, being a gas,

decreases in volume.

106

Previous Page

Previous Page