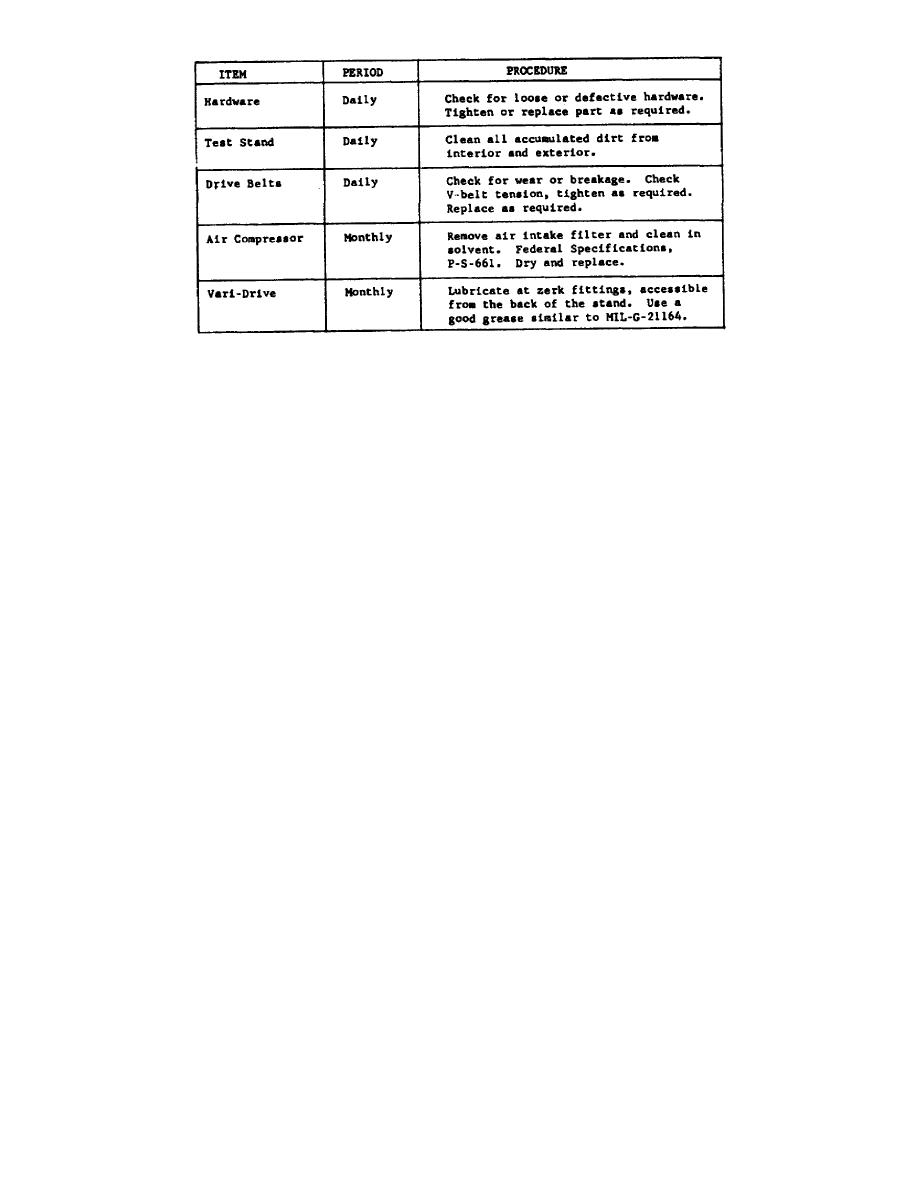

Figure 5.

Maintenance and lubrication schedule.

c. Organizational maintenance is provided the repair parts, tools, and

equipment necessary to accomplish most repairs on the distributor tester. Figure 9

details their preventive maintenance and troubleshooting responsibilities. Except

for the vacuum pump piston and valve, all moving parts of the tester are lifetime

lubricated. Lubrication of the pump is accomplished by applying six drops of OAI

instrument oil (9150-257-5449) through the vacuum hose while the pump is running.

Under normal conditions this should be done every 60 days.

7.

HEATER TEST STAND MAINTENANCE.

a. Several models of personnel and engine heaters can be performance tested

using the heater test set (FSN 4910-671-6613). The test set (fig 10) may be

operated from a 120-volt, 60-Hz, single-phase, AC power source or from a storage

battery power source. The test set is equipped with complete controls and

accessories for operating the heater under test. The test set incorporates a

cradle for mounting the heater being tested. Fuel tank, fuel filter, and electric

and voltage being supplied to the heater. An air pressure gage measures the

combustion and ventilating air blower output. A fuel flowmeter determines the rate

of fuel flow through the heater fuel control valve.

b. A circuit analyzer (fig 11) is one of the accessories of the neater test

stand. It can be used during all phases of operation to check heater electrical

circuits. The analyzer can be used with the heater installed in the vehicle or

with it mounted on the test set. Its voltage selector switch makes the analyzer

adaptable for use with 6-, 12-, and 24-volt heater units. Maintenance men can

easily check the electrical circuits of a heater by properly connecting the circuit

analyzer and observing its indicator lights as they follow the checkout procedure.

c. Operator preventive maintenance is confined to the

inspection of gages,

switches, fuel lines and fittings, exhaust duct, air pressure

lines, and electrical

wiring cables and connections. Organizational maintenance is

responsible for

periodic service and testing of the test set. Organizational

preventive

maintenance checks and services are shown in figure 12.

OS 010, 8-P9

Previous Page

Previous Page