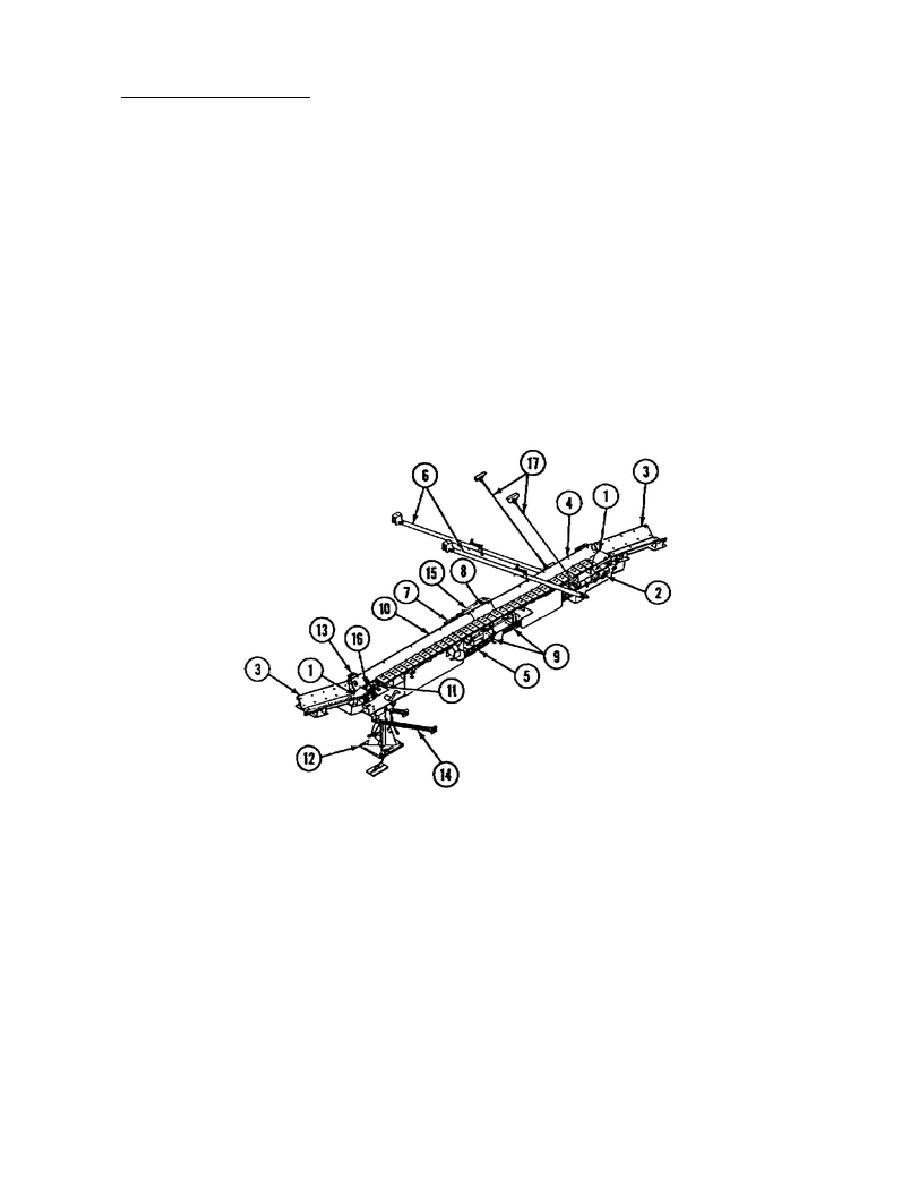

2.

The Conveyor Assembly.

The conveyor is a hydraulically powered assembly that can be operated in either the

forward or reverse directions. Two stationary dead end sections, one at each end,

are used as staging areas for ammunition transfer.

The powered parts of the

conveyor are the drive end, center, and take-up end sections.

A three position

switch located on the hydraulic control panel actuates the solenoids attached to

the conveyor directional control valve. This allows the conveyor motor to operate

in either forward or reverse. An override safety (ON/OFF) switch, located at the

take-up end section, provides a shut-off capability outside of the vehicle.

A

drive sprocket coupled to the motor shaft moves the conveyor chain.

The chain runs taut across the top of the conveyor and loose across the bottom. A

chain adjustment device allows chain tension to be adjusted by moving the idler

sprocket forward or backward.

Telescoping support arms serve to adjust and lock

the conveyor in several operating positions.

Two cable assemblies support the

conveyor while it is being deployed.

They are removed and stowed when it is in

operation. A handcrank, for manual operation, is provided in case of a hydraulic

system malfunction. The conveyor can be folded and stowed inside the vehicle when

not in use (Fig. 1).

Figure 1.

Conveyor Assembly.

You have completed the introduction to the M992 Ammunition Carrier and the

description of the conveyor assembly. The next part of this lesson describes the

maintenance procedures for the components of the conveyor assembly.

3

OD1737

Previous Page

Previous Page