o Shift lever housing.

o Solenoid plunger.

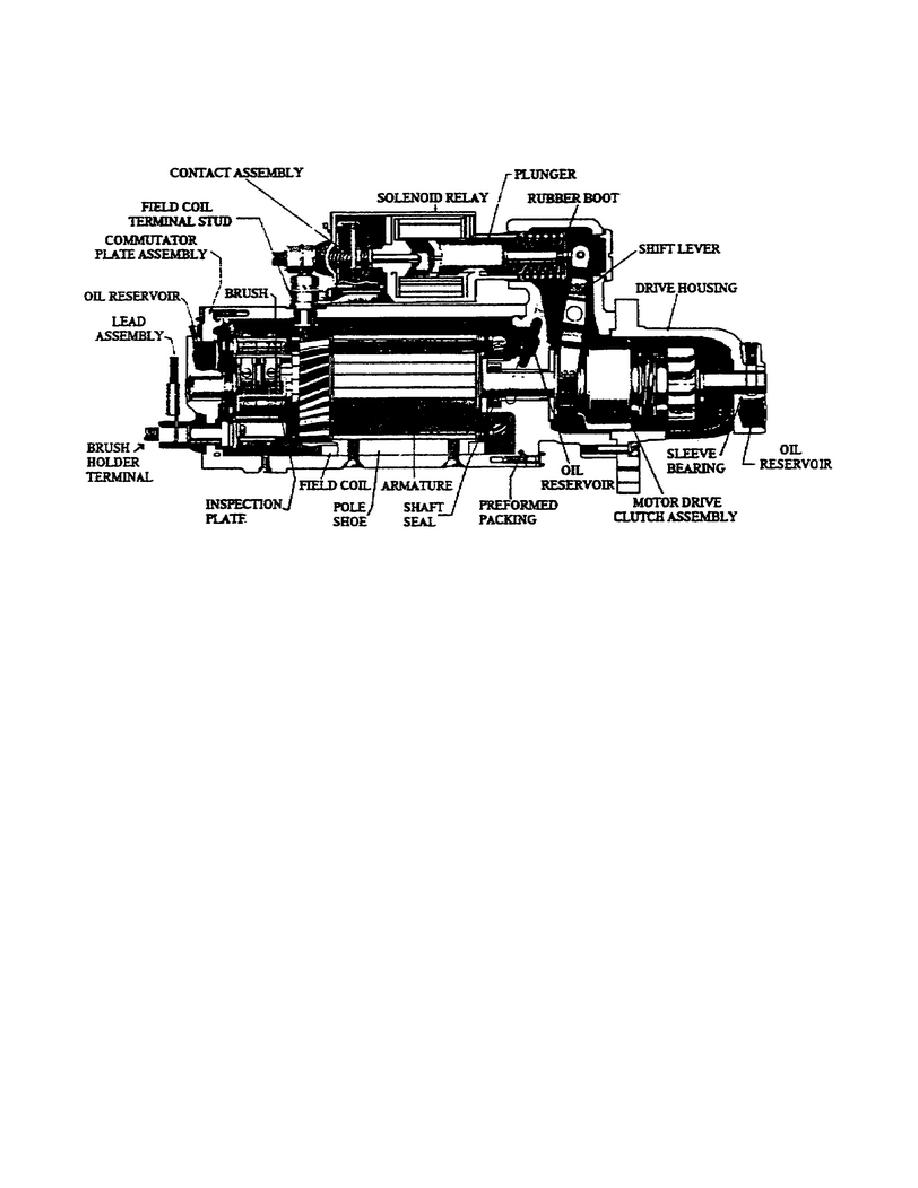

Figure 16.

Starter Motor.

u. The Blower Assembly (Fig. 17).

The blower assembly bolts on

the cylinder block and supplies fresh air for the engine to use

during scavenging, intake, and compression.

Basically it is an air

pump; two hollow double lobe rotors revolve in a housing, providing a

continuous and uniform flow of air into the engine air box.

This engine uses a bypass blower and bypass relief valve. The spring

loaded bypass valve is at the rear of the blower end plate.

The

valve is closed at engine start-up, during low rpm, and during light

load conditions. As engine speed and rpm increase, the turbocharger

speed increases causing an increase in the air box pressure for

scavenging the engine cylinders.

At 10" Hg air box pressure, the

bypass valve begins to open; it is fully open at 13" Hg.

With the

valve in the open position, this allows incoming air to flow through

the blower lobes and end plate to the airbox. The blower continues

to operate with the valve open, but requires less engine power

because the pressure rise across the blower is greatly reduced,

resulting in increased fuel economy.

Viewed externally, the bypass valve is a small hose and tube through

the blower end plate.

A very small amount of air bleeds past the

valve and passes through the hose to help keep the

21

OD1713

Previous Page

Previous Page