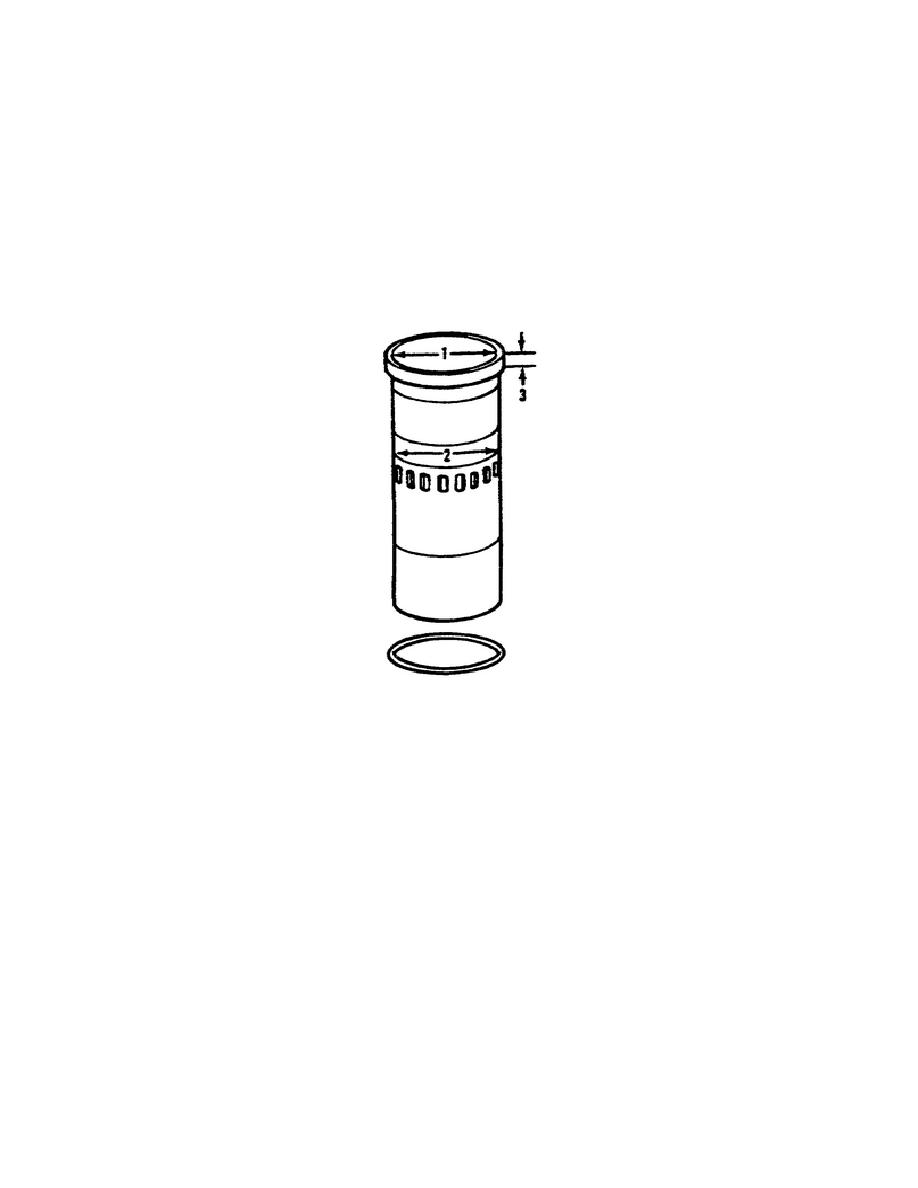

ring, recessed in the cylinder block bore between

the

liner

and

block, prevents water from leaking into the air box.

The liner's upper portion receives cooling from the water surrounding

it.

The center section of the liner receives cooling from the

scavenging air entering the cylinder through the 18 equally spaced

ports in the liner. The water inside the cylinder block water jacket

surrounds the liner's lower portion, thereby cooling it.

The angle

of the inlet ports, in the cylinder liner, creates a uniform swirling

motion with the intake air as it enters the cylinder.

This motion

persists throughout the compression stroke and facilitates scavenging

and combustion.

Figure 6.

Cylinder Liner.

c. The Crankshaft (Fig. 7).

The crankshaft is one-piece, heat

treated, and steel forged with all main and connecting rod bearing

journals and oil seal surfaces induction-hardened.

Counterweights,

incorporated in the crankshaft, ensure complete static and dynamic

balance.

Thrust washers, at the rear main bearing cap, control the

end thrust of the crankshaft.

All connecting rod and main bearings

receive lubrication, under pressure, through drilled passages in the

crankshaft and block. A press-fit timing gear is on the rear of the

crankshaft, and a press fit oil pump drive gear is on the front of

the crankshaft.

d. The Flywheel and Adapter Plate (Fig. 7). Attached to the rear

of the crankshaft is the flywheel.

Six bolts and a scuff plate,

between the flywheel and bolt heads to prevent the bolts from

damaging the flywheel, secure the flywheel to the

10

OD1713

Previous Page

Previous Page