MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 1

cs

=

cutting speed of milling cutter

(in surface feet per minute)

D

=

diameter of milling cutter (in inches).

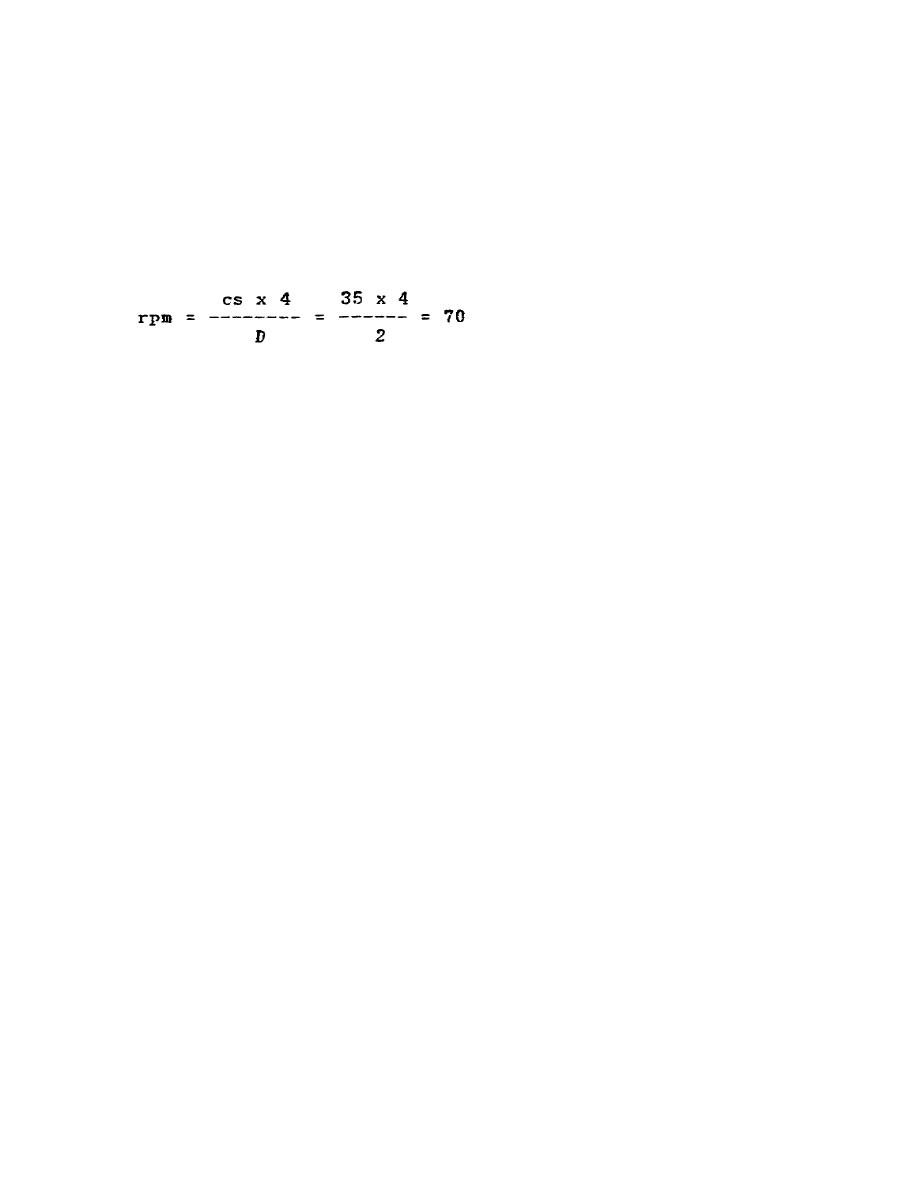

For example, the spindle speed for machining a piece of steel at a speed of

35 rpm with a cutter 2 inches in diameter is calculated as follows:

Therefore, the milling machine spindle would be set for as near 70 rpm as

possible.

If the calculated rpm cannot be obtained, the next lower

selection should be made.

(b)

Table 2 on page 32 is provide to facilitate spindle speed

computations for standard cutting speeds and standard milling cutters.

d.

Feeds For Milling.

(1)

General.

The rate of feed, or the speed at which the workpiece

passes the cutter, determines the time required for cutting a job.

In

selecting the feed, there are several factors which should be considered.

These factors are:

(a)

Forces are exerted against the workpiece, the cutter, and their

holding devices during the cutting process.

The force exerted varies

directly with the amount of metal removed and can be regulated by the feed

and the depth of cut.

Therefore, the correct amount of feed and depth of cut are interrelated, and

in turn are dependent upon the rigidity and power of the machine. Milling

machines are limited by the power that they can develop to turn the cutter

and the amount of vibration they can resist when using coarse feeds and deep

cuts.

(b)

The feed and depth of cut also depend upon the type of milling

cutter being used.

For example, deep cuts or coarse feeds should not be

attempted when using a small diameter end milling cutter, as such an attempt

would spring or break the

31

Previous Page

Previous Page