MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 1

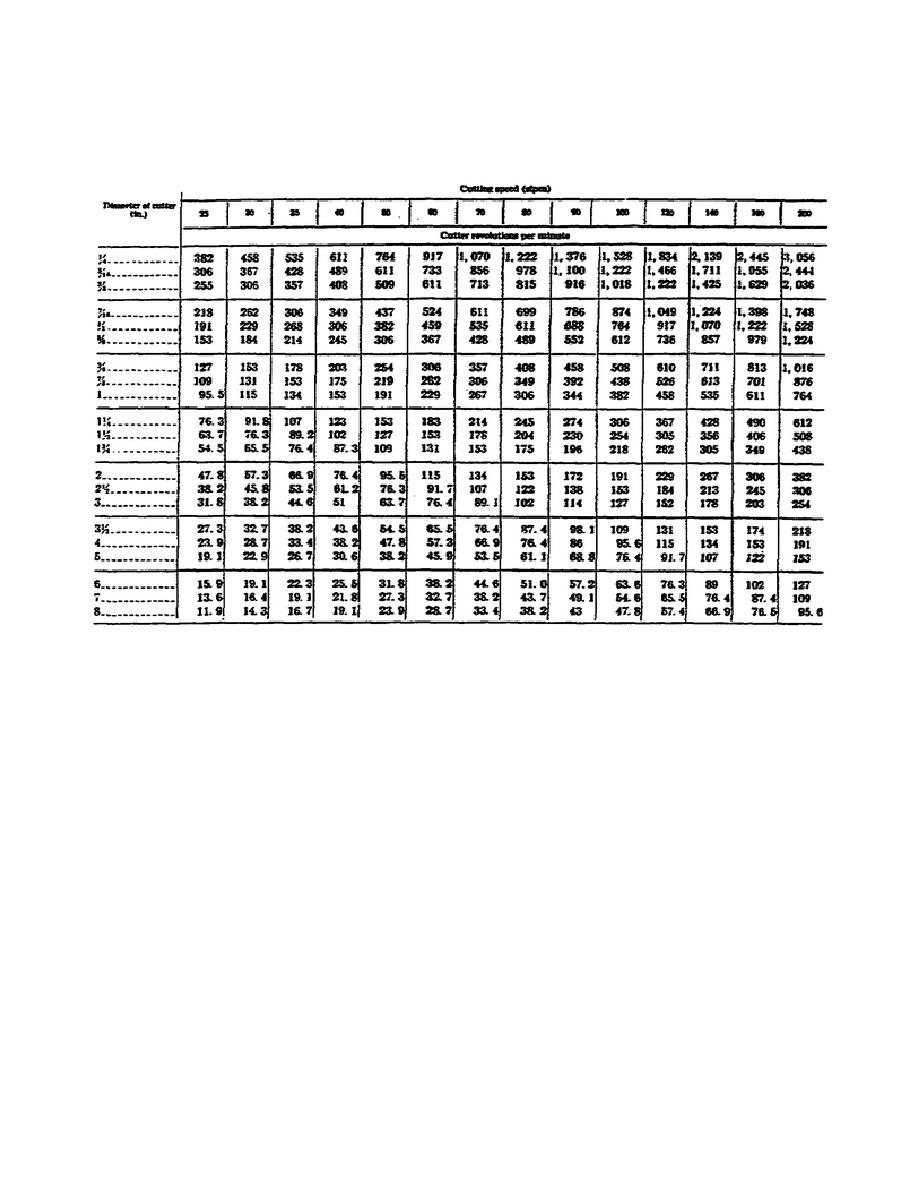

TABLE 2.

MILLING CUTTER ROTATIONAL SPEEDS.

cutter.

Coarse cutters with strong cutting teeth can be fed at a faster

rate because the chips may be washed out more easily by the cutting oil.

(c)

Coarse feeds and deep cuts should not be used on a frail workpiece,

or on a piece that is mounted in such a way that its holding device is not

able to prevent springing or bending.

(d)

The degree of finish required often determines the amount of feed.

Using a coarse feed, the metal is removed more rapidly but the appearance

and accuracy of the surface produced may not reach the standard desired for

the finished product. Because of this, finer feeds and increased speeds are

used for finer, more accurate finishes.

Most mistakes are made through

overspeeding, underspeeding, and overfeeding. Overspeeding may be detected

by the occurrence of a squeaking, scraping sound. If vibration (referred to

as "chattering") occurs in the milling machine during the cutting process,

the speed should be

32

Previous Page

Previous Page