MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 1

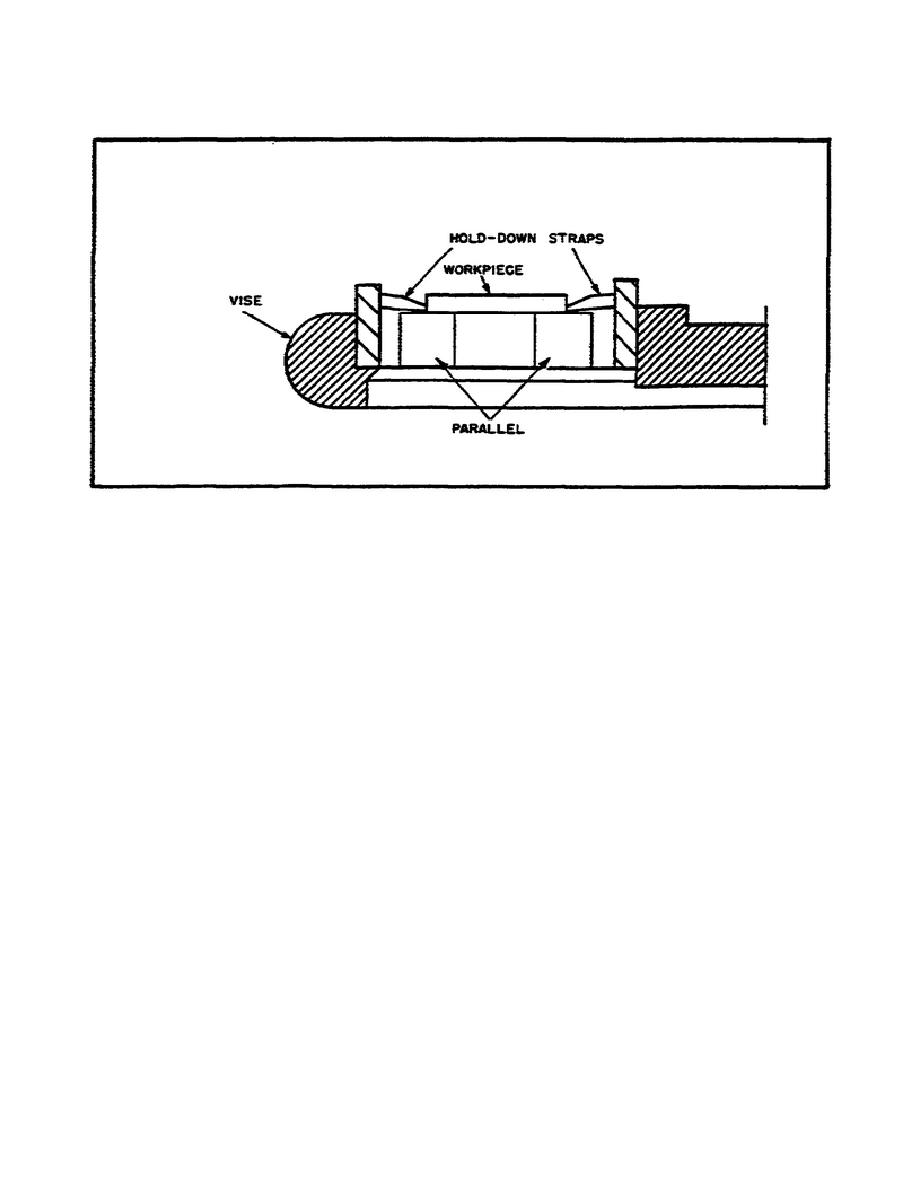

FIGURE 9.

APPLICATION OF HOLDDOWN STRAPS.

(2)

Index Head.

The bead of the indexing fixture contains an indexing

mechanism, used to control the rotation of the index head spindle in order

to space or divide a workpiece accurately. A simple indexing mechanism is

illustrated in figure 10 on the following page. It consists of a 40-tooth

worm wheel fastened to the index head spindle, a single-cut worm, a crank

for turning the wormshaft, and an index plate and sector. Since there are

40 teeth in the worm wheel, one turn of the index crank causes the worm

wheel, and consequently the index head spindle to, make one-fortieth of a

turn; so 40 turns of the index crank revolves the spindle one full turn.

(3)

Plain Indexing.

The following principles apply to basic indexing of

workpieces:

(a)

Suppose it is desired to mill a spur gear with 8 equally spaced

teeth.

Since 40 turns of the index crank will turn the spindle one full

turn, one-eighth of 40, or 5 turns of the crank after each cut, will space

the gear for 8 teeth.

(b)

The same principle applies whether or not the divisions required

divide evenly into 40.

For example, if it is desired to index for 6

divisions, 6 divided into 40 equals 6 2/3 turns; similarly, to index for 14

spaces, 14 divided into 40 equals 2 6/7 turns.

Therefore, the following

rule can be derived: to determine the number of turns of the index crank

needed to obtain one division of any number of equal divisions on the

workpiece, divide

22

Previous Page

Previous Page