MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 1

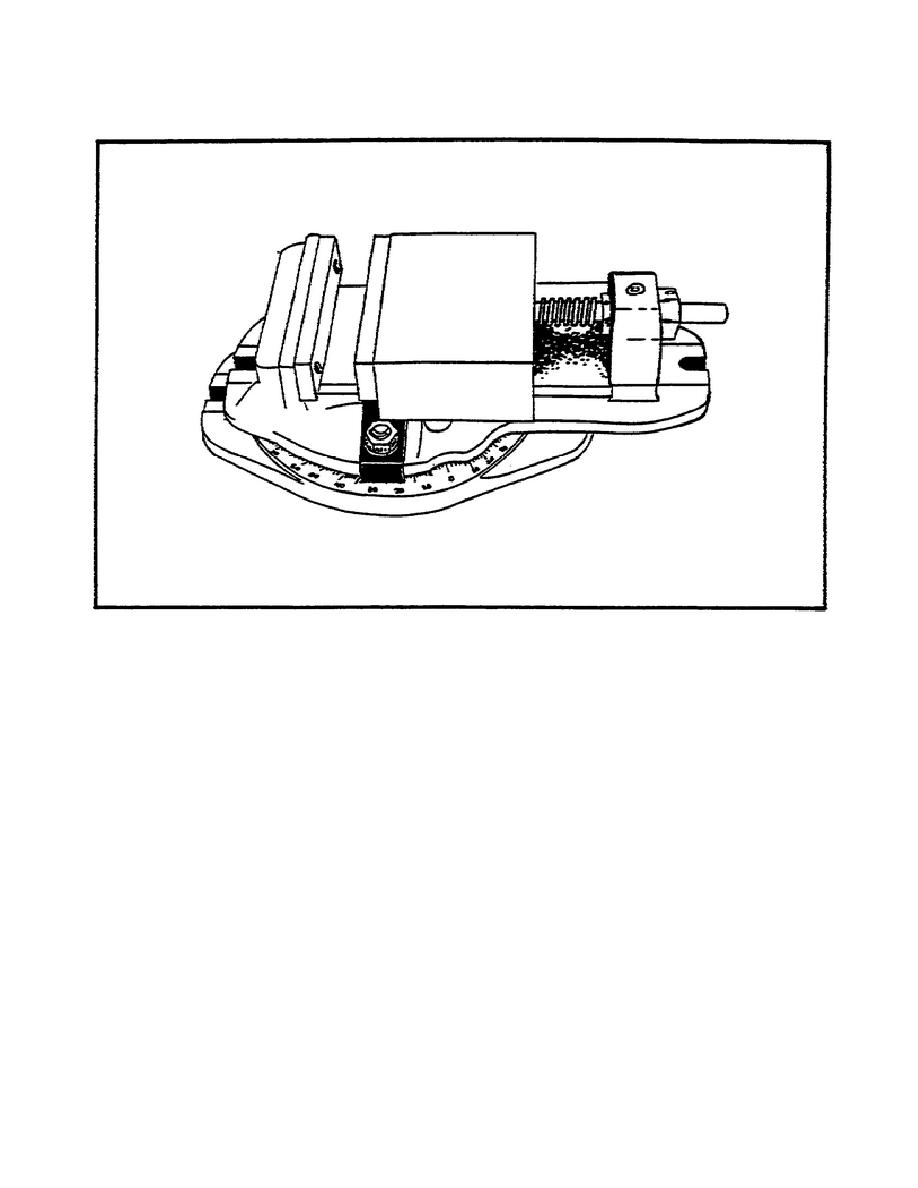

FIGURE 7.

UNIVERSAL VISE.

This tapping should be continued until the parallels cannot be moved by

hand.

After once set, additional tightening has a tendency to raise the

work off the parallels.

(f)

If the workpiece is so thin that it is impossible to let it extend

over the top of the vise, holddown straps, such as those illustrated in

figure 9 on page 22, are generally used. These straps are hardened pieces

of steel, having one vertical side tapered to form an angle of about 92

degrees with the bottom side and the other vertical side tapered to a narrow

edge. By means of these tapered surfaces, the workpiece is forced downward

onto the parallels, holding them firmly and leaving the top surface of the

workpiece fully exposed to the milling cutter.

(g)

Whenever possible, the workpiece should be clamped in the center of

the vise Jaws (see figure 8 on the following page); however, when necessary

to mill a short workpiece which must be held at the end of the vise, a

spacing block of the same thickness as the piece (see figure 8) should be

placed at the opposite ends of the jaws.

This will avoid strain on the

movable jaw and prevent the piece from slipping.

20

Previous Page

Previous Page