PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

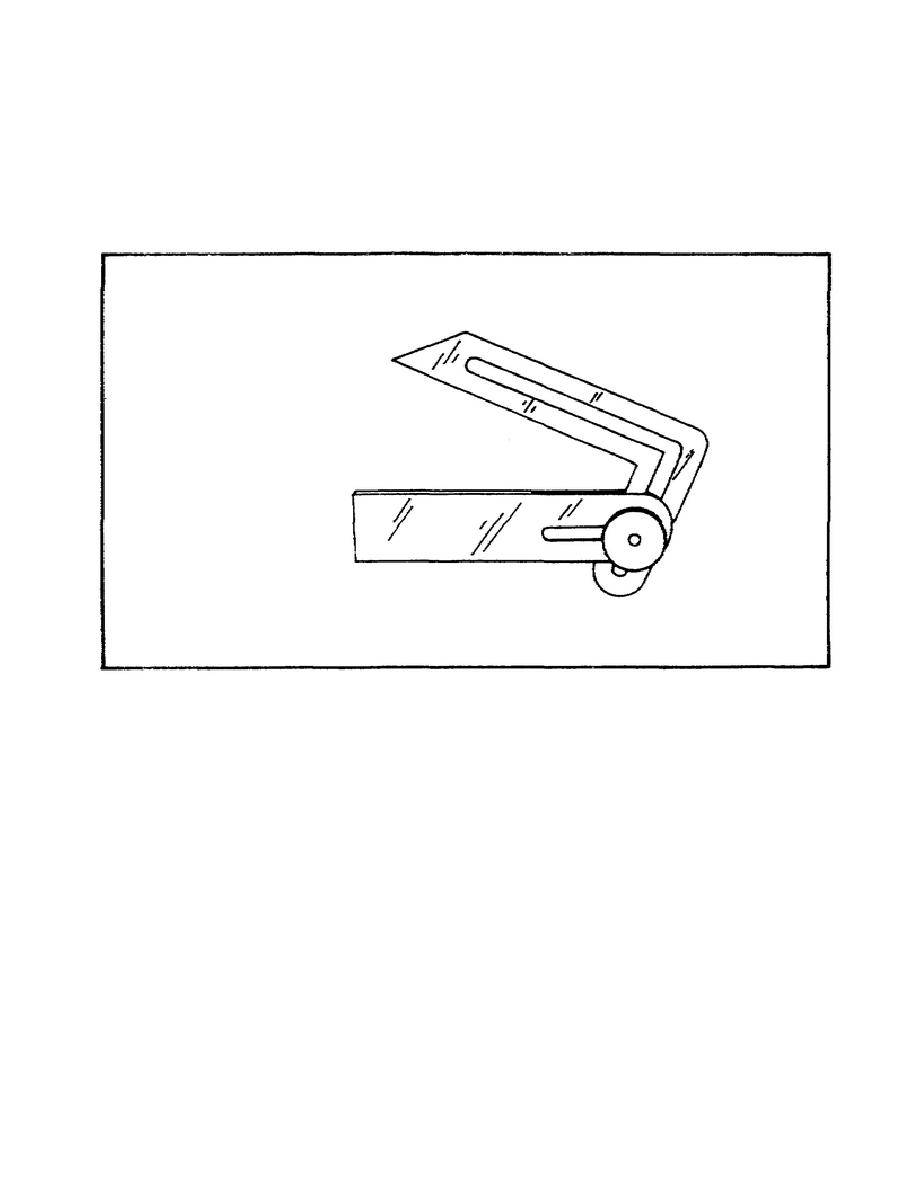

(8) Universal Bevel. The universal bevel (figure 7), because of the

offset in the blade, is very useful for bevel gear work and for checking

angles on lathe workpieces which cannot be reached with an ordinary bevel.

The universal bevel must be set and checked with a protractor, or another

suitable angle-measuring device, to obtain the desired angle.

FIGURE 7.

UNIVERSAL BEVEL.

(9) Cutter Clearance Gage.

The cutter clearance gage (figure 8 on

the following page) is one of the simplest gages to use, yet it is suitable

for gaging clearance on all styles of plain milling cutters which have more

than 8 teeth and a diameter range from 1/2 inch to 8 inches.

To gage a

tooth with the instrument, bring the surfaces of the "V" into contact with

the cutter and lower the gage blade upon the tooth to be gaged. Rotate the

cutter sufficiently to bring the tooth face into contact with the gage

blade.

If the angle of clearance on the tooth is correct, it will

correspond with the angle of the gage blade.

Cutter clearance gages that

have an adjustable gage blade for checking clearance angles of 0ƒ-30ƒ on

most common cutter styles are also available.

18

Previous Page

Previous Page