PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

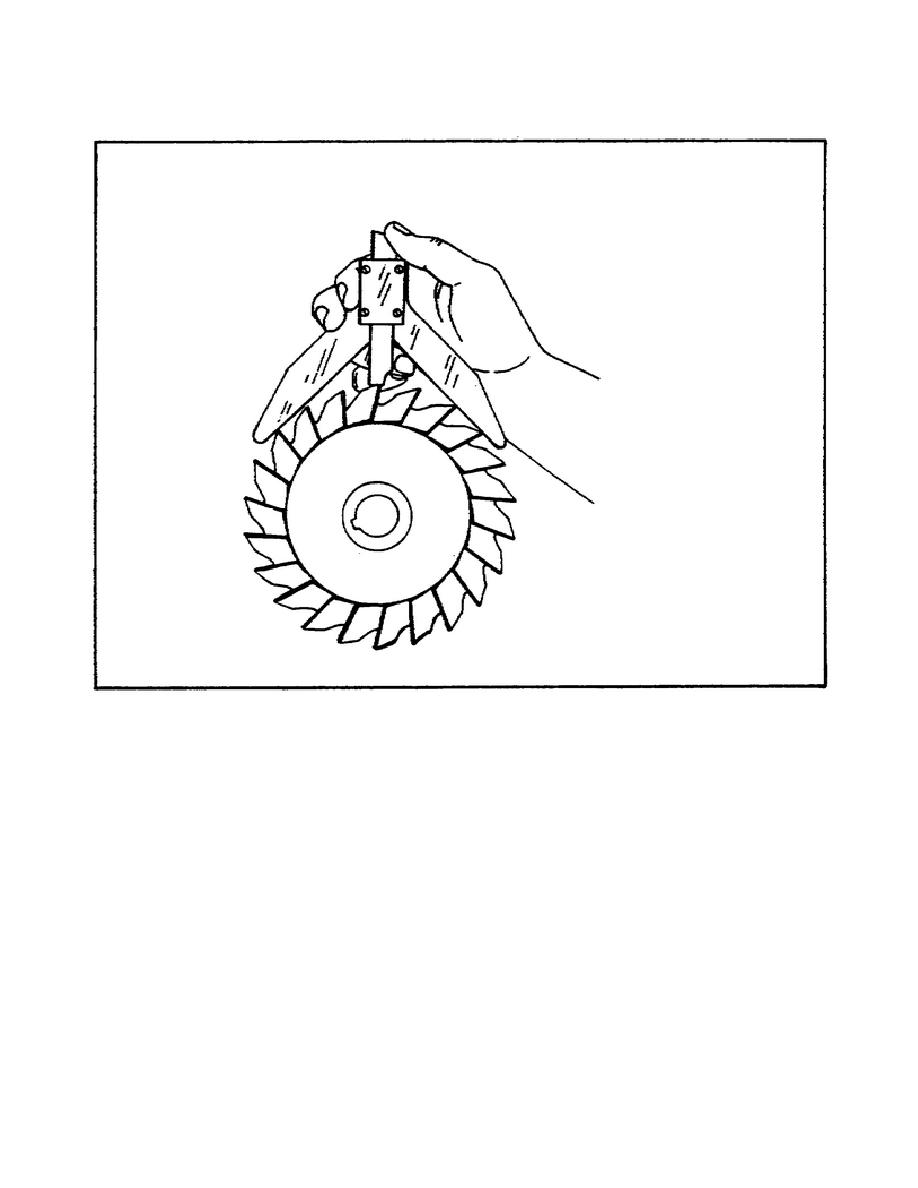

FIGURE 8.

CUTTER CLEARANCE GAGE.

(10) Adjustable Parallel.

The adjustable parallel (figure 9 on the

following page) consists of two wedges connected on their inclined surfaces

by a sliding dovetail.

The distance between the two outside parallel

surfaces is varied by moving the mating parts together or apart.

The

distance is then measured with a micrometer. An adjustable parallel can be

locked at any height between the maximum and the minimum limits.

This

instrument, constructed to about the same accuracy of dimensions as parallel

blocks, is very useful in leveling and positioning setups in a milling

machine or in a shaper vise. Adjustable parallels are available in various

sizes depending on the nature of the work.

(11) Surface Gage. A surface gage (figure 10 on page 21) is used to

measure or gage an object and to indicate the parallelism of surfaces. It

is used primarily in layout and alignment of the work. The surface gage is

commonly used with a surface plate and a scriber to transfer dimensions and

layout lines to the work. In some cases, a dial

19

Previous Page

Previous Page