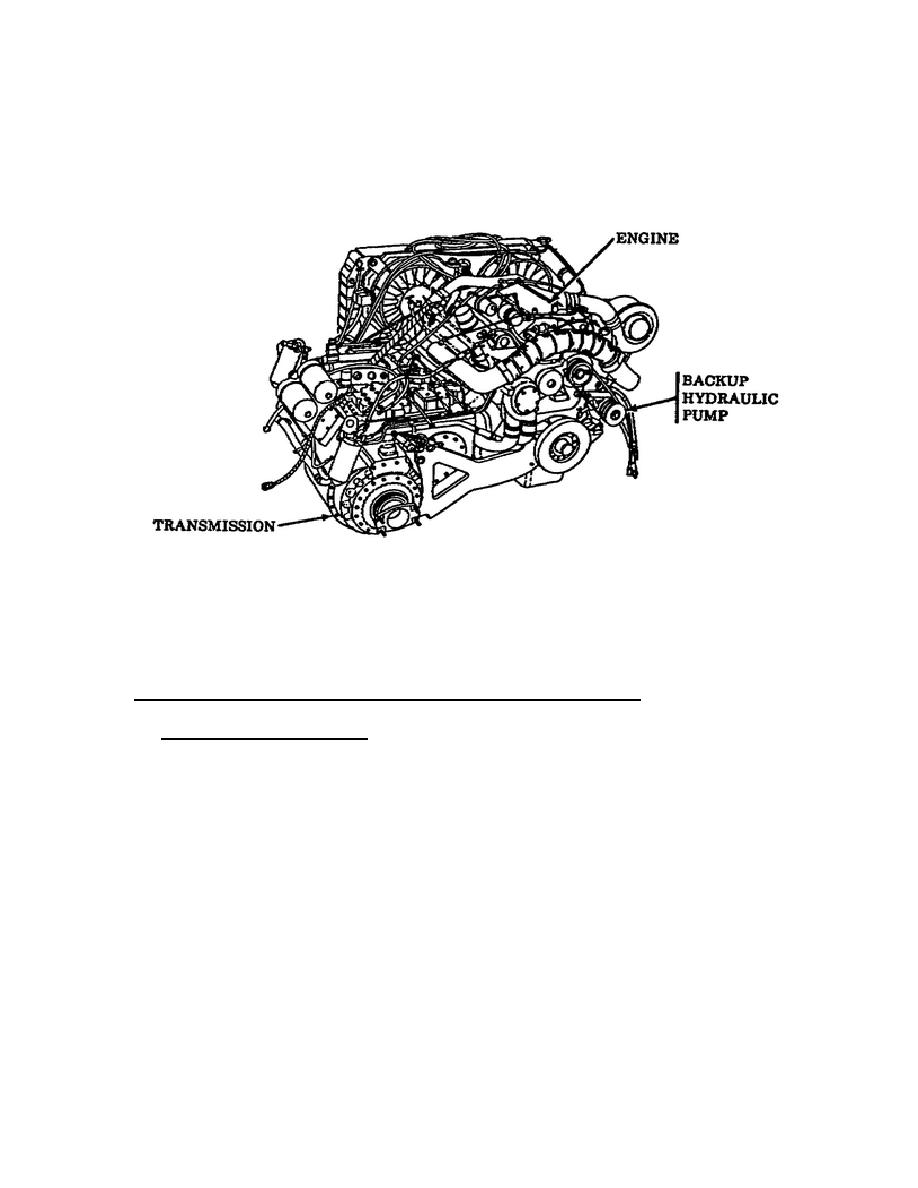

maximum (Fig. 3F). This pressure, held by a check valve, engages

the backup system clutch, which activates the belt-driven backup

pump mounted on the main engine (Fig. 4).

The engine-mounted

hydraulic backup pump delivers 7.1 gpm of flow at a system

pressure of 1550 psi with the engine operating at 1100

revolutions per minute (rpm).

Figure 4.

Backup Hydraulic Pump.

To disengage the backup hydraulic system pump, open the pressure

release check valve to release hydraulic fluid pressure, and push

the selector valve in.

This will allow the primary hydraulic

pump to provide the hydraulic fluid for system operation.

3.

Subsystems of the Primary/Backup Hydraulic System.

o The Conveyor System.

The conveyor is a hydraulically powered

system that can be operated in either the forward or reverse

direction (Fig. 5F). Use two stationary dead-end sections, one

at each end, as staging areas for ammunition transfer.

The

powered or moving parts of the conveyor are: drive end, center,

and take-up end sections.

A three position switch, located in the hydraulic control panel,

actuates the solenoids attached to the conveyor directional

control valve which allows the conveyor motor to operate in

either forward or reverse. A drive sprocket coupled to the motor

shaft moves the conveyor chain.

An override safety (ON/OFF)

switch, located at

6

OD1703

Previous Page

Previous Page