b. Either type of stator winding may be checked for grounds by connecting

an ohmmeter or test light from either terminal to the stator frame. The windings

are grounded if the ohmmeter reads low or if the lamp lights.

c. If all checks are satisfactory, including the diode tests listed below,

but the generator fails to provide rated output, a shorted Y -or delta stator

winding or an open delta winding can be suspected.

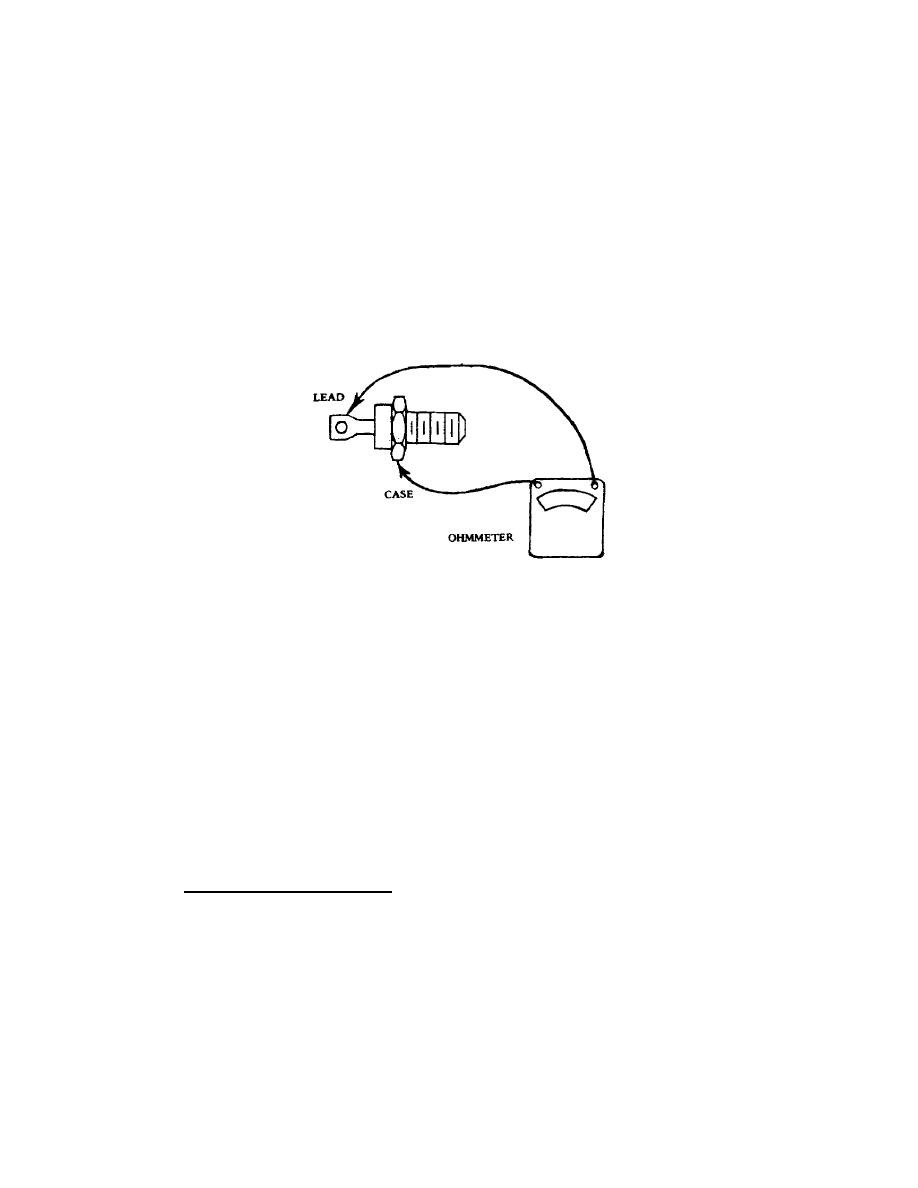

6. DIODE CHECKS. Diodes when disconnected from the stator can be checked for

defects with an ohmmeter having a 1-1/2-volt cell. Using the lowest range scale,

connect the ohmmeter leads to the diode case and the diode stem and then reverse

the connections (fig 5). On push-in type diodes, if both readings are very low,

the diode is shorted. If both readings are very high, the diode is open. On

threaded-type diodes, if both readings are below 300 ohms or if both readings are

above 300 ohms, the diode is defective. The 300-ohm value should be near midscale

for accuracy. A good diode will give one very low and one very high reading.

CAUTION: Do not use high voltage such as a 110-volt test light to check diodes.

Figure 5.

Diode checks.

SECTION III.

DISASSEMBLY, TESTING, AND ASSEMBLY OF THE 40/60-AMPERE

AC GENERATOR.

7.

DISASSEMBLY.

a.

Remove pulley nut and washer.

b.

Remove pulley using puller (fig 6).

c.

Remove woodruff key from shaft.

d.

Remove six socket-head screws from drive end housing (fig 7).

e.

Remove drive end housing (using puller)(fig 8).

8.

RECTIFIER TEST.

a.

Positive heat sink test.

(1) Select low ohmmeter range.

(2) Zero the ohmmeter.

(3) Connect one ohmmeter lead to checkpoint 2 (fig 9) and the other

ohmmeter lead to splice 1, then 2 and 3 (fig 10), while observing the meter. Note

the readings obtained.

OS 010, 2-P5

Previous Page

Previous Page