BANDSAW OPERATIONS - OD1646 - LESSON 2/TASK 1

replaced, when required.

The bearings are sealed and packed for life with a

special lubricant.

e.

Drive Belts.

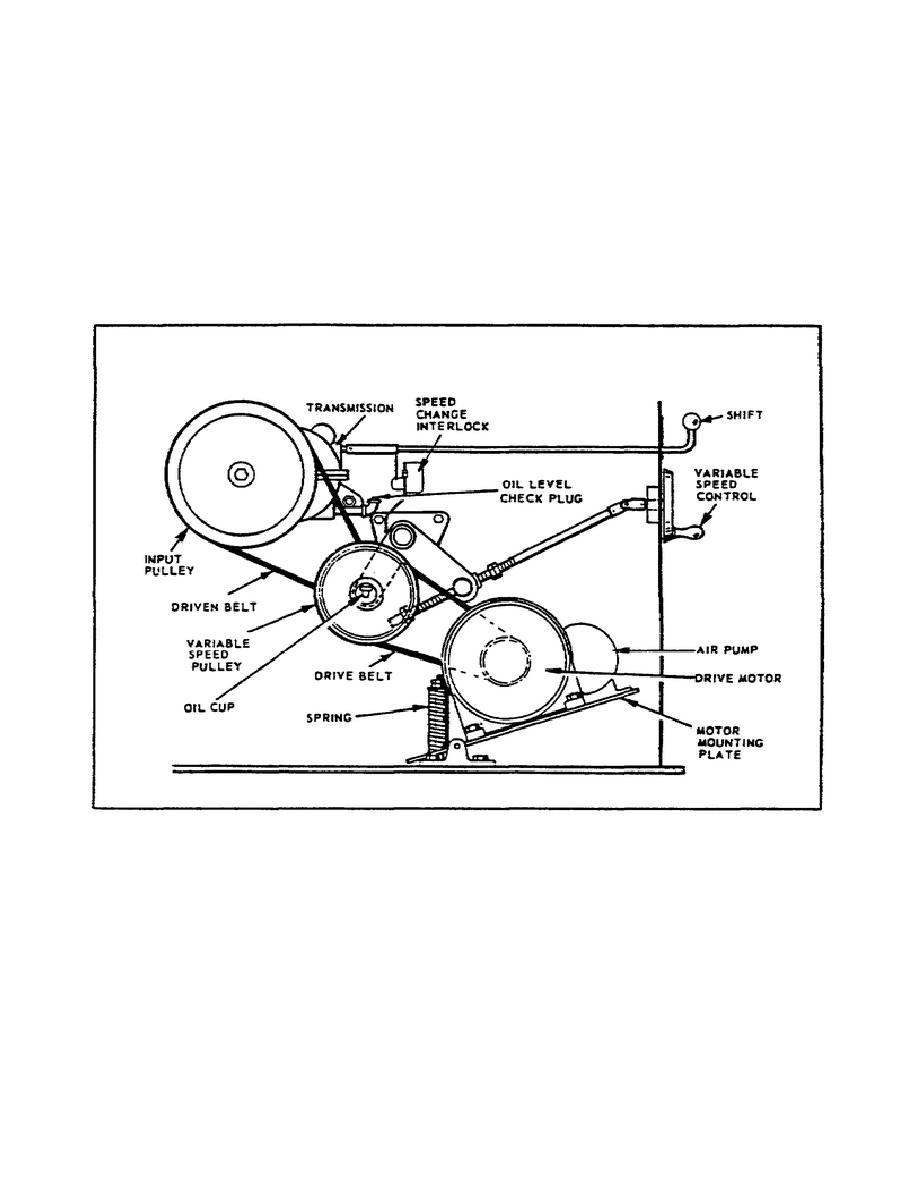

The belts driving the variable pulley and input sheave

will stretch slightly after initial use.

The stretch of the belts is

automatically taken up by the counterbalancing weight of the drive motor on

its mounting plate (figure 40).

The motor is mounted on a pivoted plate.

The large spring to the left of the pivot is adjusted to counterbalance the

weight of the motor on the drive belts.

FIGURE 40.

BELT DRIVE SYSTEM - MODEL 2612-1M.

(1) Adjusting the Belts.

To adjust the belts, adjust the nuts on the

counterbalance spring so that there is enough tension on the drive belts to

prevent slippage.

If the motor is insufficiently counterbalanced,

unnecessary wear on the variable pulley sheaves, bearings, and shaft will

result. Too much counterbalance will cause the motor to "climb the belt" or

"hop" excessively.

(2) Changing the Belts.

To change the belts on the model 2612-1M

bandsaw machine, perform these steps:

60

Previous Page

Previous Page