MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 2

without changing the width of the slot that will be machined. After each

sharpening, a washer is placed between the two cutters to compensate for the

ground-off metal.

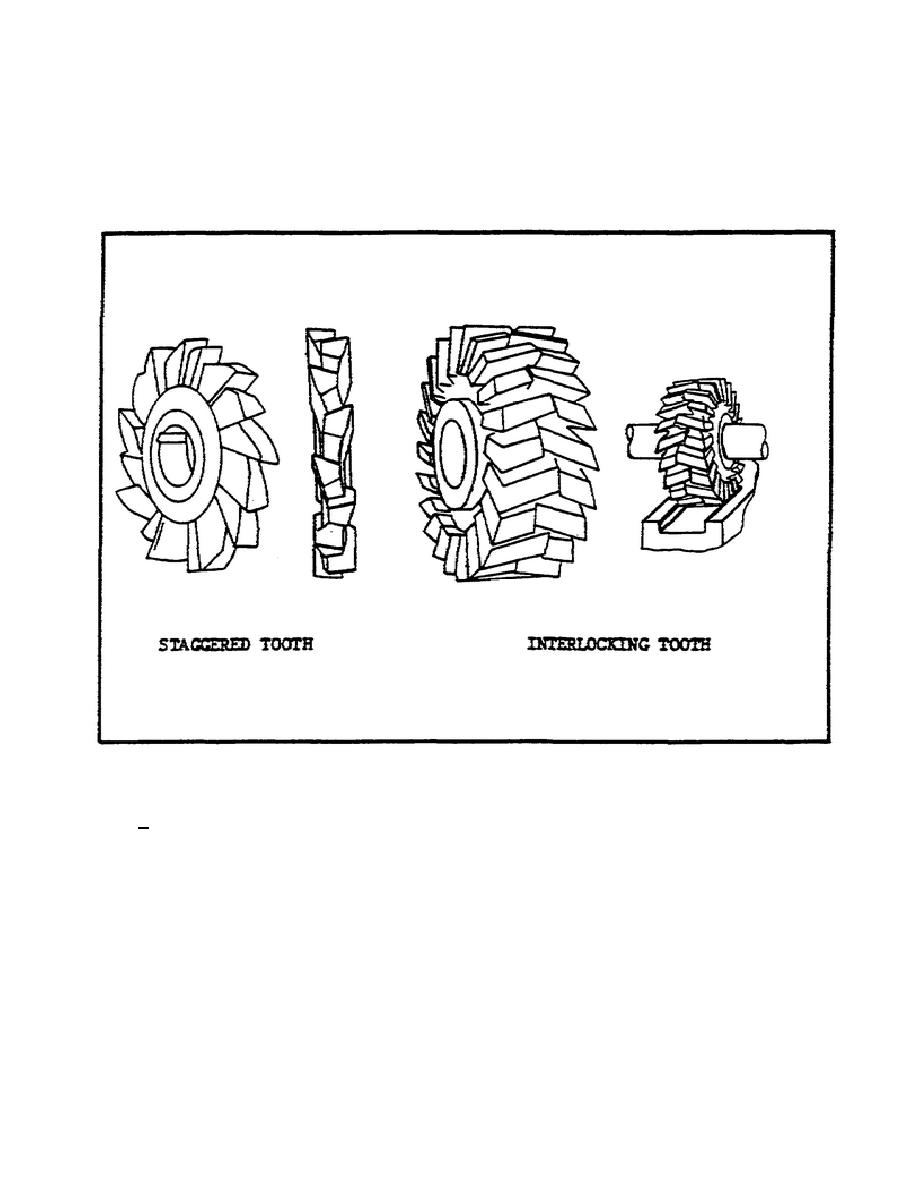

The staggered tooth cutter is the most efficient type

used for milling slots where the depth exceeds the width.

FIGURE 26.

SIDE MILLING CUTTERS.

(d)

End Milling Cutters.

1

End milling cutters, also called end mills, have teeth on the end

as well as the periphery (figure 27 on the following page). The smaller end

milling cutters have shanks for chuck mounting or direct spindle mounting.

Larger end milling cutters (over 2 inches in diameter) are called shell end

milling cutters and are mounted on arbors like plain milling cutters. End

milling cutters are employed in the production of slots, keyways, recesses,

and tangs. They are also used for milling angles, shoulders, and the edges

of workpieces.

61

Previous Page

Previous Page