MILLING MACHINE OPERATIONS - OD1644 - LESSON 1/TASK 2

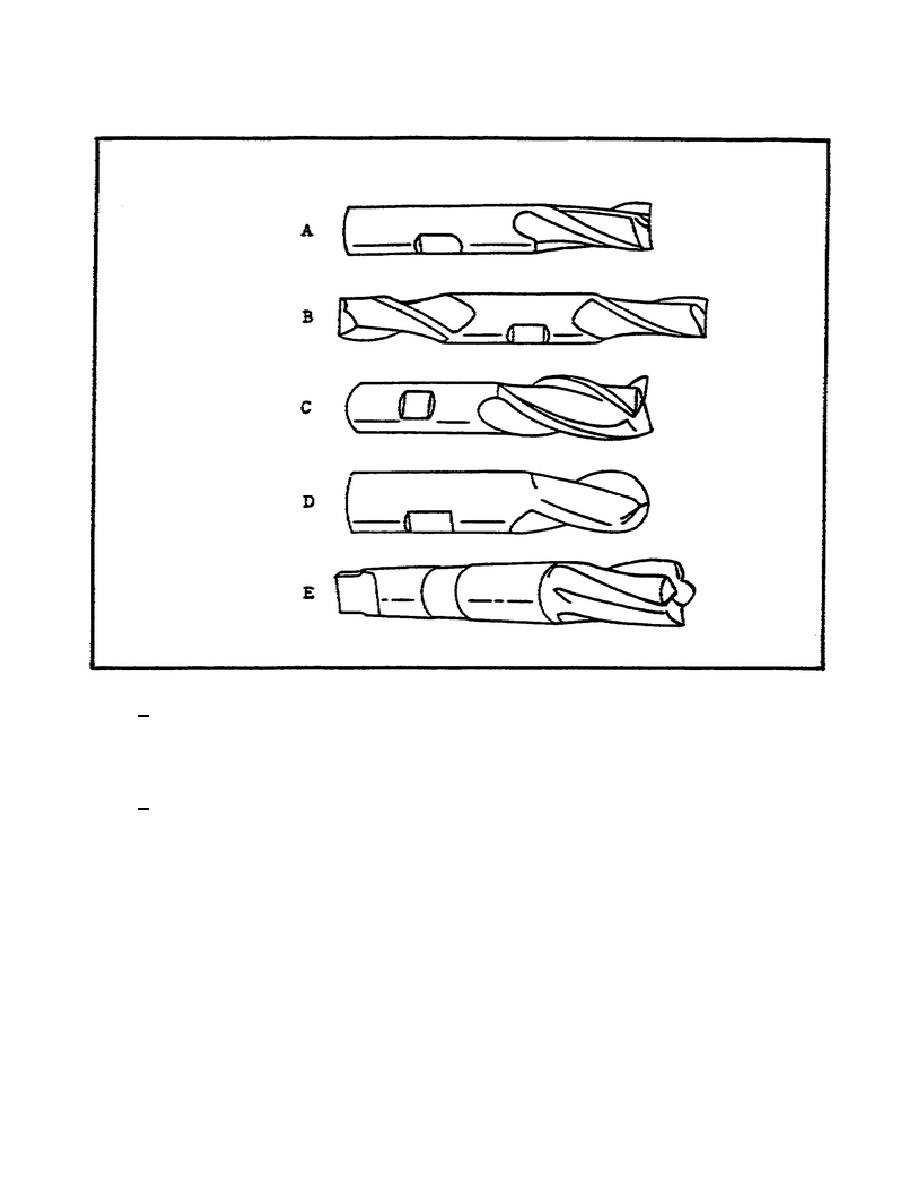

FIGURE 27.

END MILLING CUTTERS.

2

End milling cutters may have straight or spiral flutes.

Spiral

flute end milling cutters are classified as left-hand or right-hand cutters,

depending on the direction of rotation of the flutes.

If they are small

cutters, they may have either a straight or tapered shank.

3

Several common types of end milling cutters are illustrated in

figure 27.

The most common end milling cutter is the spiral flute end

milling cutter, which contains four flutes. Two fluted end milling cutters

are used for milling slots and keyways where no drilled hole is provided for

starting the cut. These cutters drill their own starting holes. Straight

flute end milling cutters are generally used for milling soft or tough

materials, while spiral flute cutters are used mostly for cutting steel.

(e)

Face Milling Cutter.

Face milling cutters are cutters of large

diameter having no shanks.

They are fastened directly to the milling

machine spindle with adapters. Face milling machine cutters are generally

made with inserted teeth of

62

Previous Page

Previous Page