PRECISION MEASURING AND GAGING - OD1642 - LESSON 1/TASK 2

rod from left to right and in and out of the hole.

The micrometer is

adjusted to a slightly larger measurement after each series of rocking

movements until no rocking from left to right is possible and a very slight

drag is felt on the in and out rocking movement.

There are no specific

guidelines on the number of positions within a hole that should be measured.

When checking for a taper, the measurements should be made as far apart as

possible within the hole. When checking for roundness or concentricity of a

hole, several measurements should be taken at different angular positions in

the same area of the hole. A reading can be taken directly from the inside

micrometer head, or an outside micrometer may be used to measure the inside

micrometer.

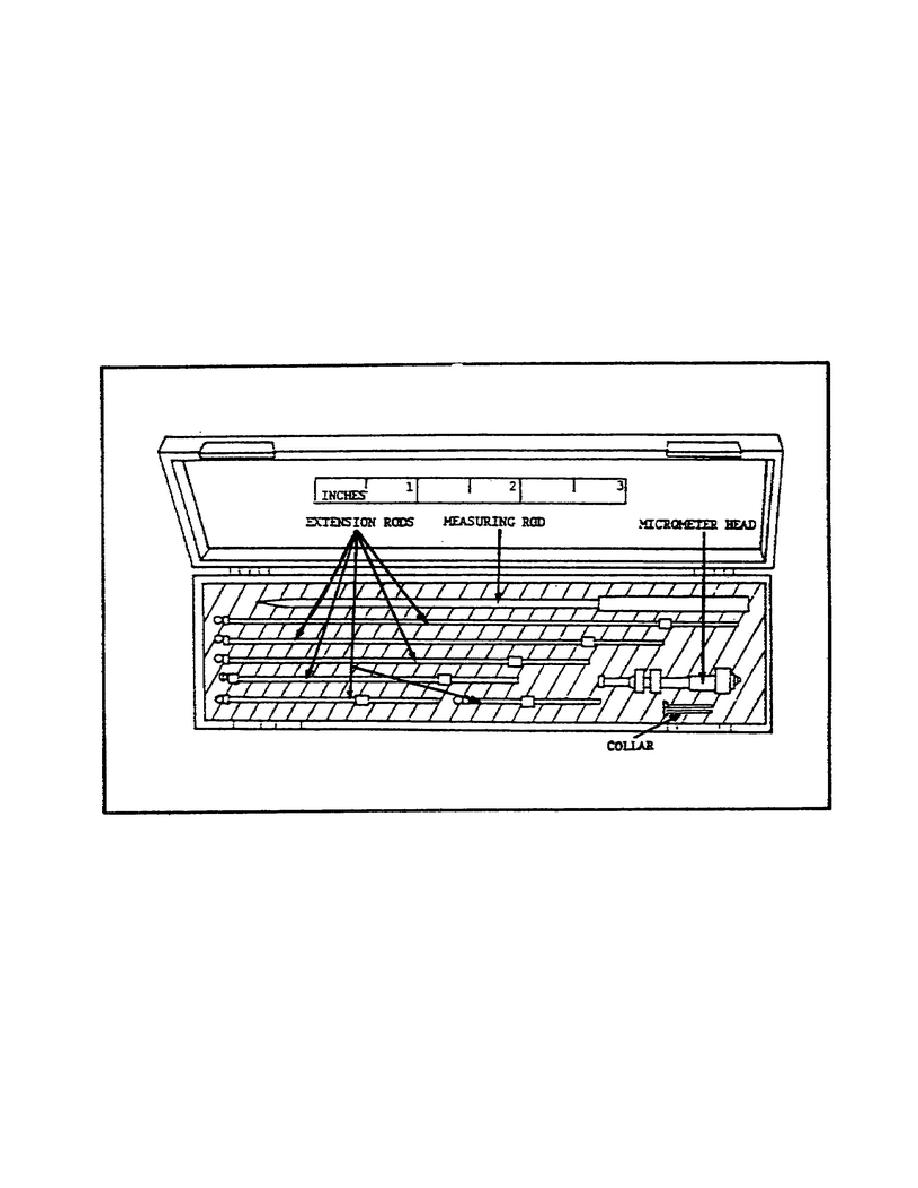

FIGURE 42.

INSIDE MICROMETER SET.

(b) The normal procedure in using an inside micrometer is to set

it across a diameter or between the inside surfaces, remove it, then read

the dimension. For this reason, the thimble on an inside micrometer is much

stiffer than the one used on an outside micrometer and it holds the

dimensions well.

It helps at times to verify the reading of an inside

micrometer by measuring it with an outside micrometer.

64

Previous Page

Previous Page