BANDSAW OPERATIONS - OD1646 - LESSON 1/TASK 1

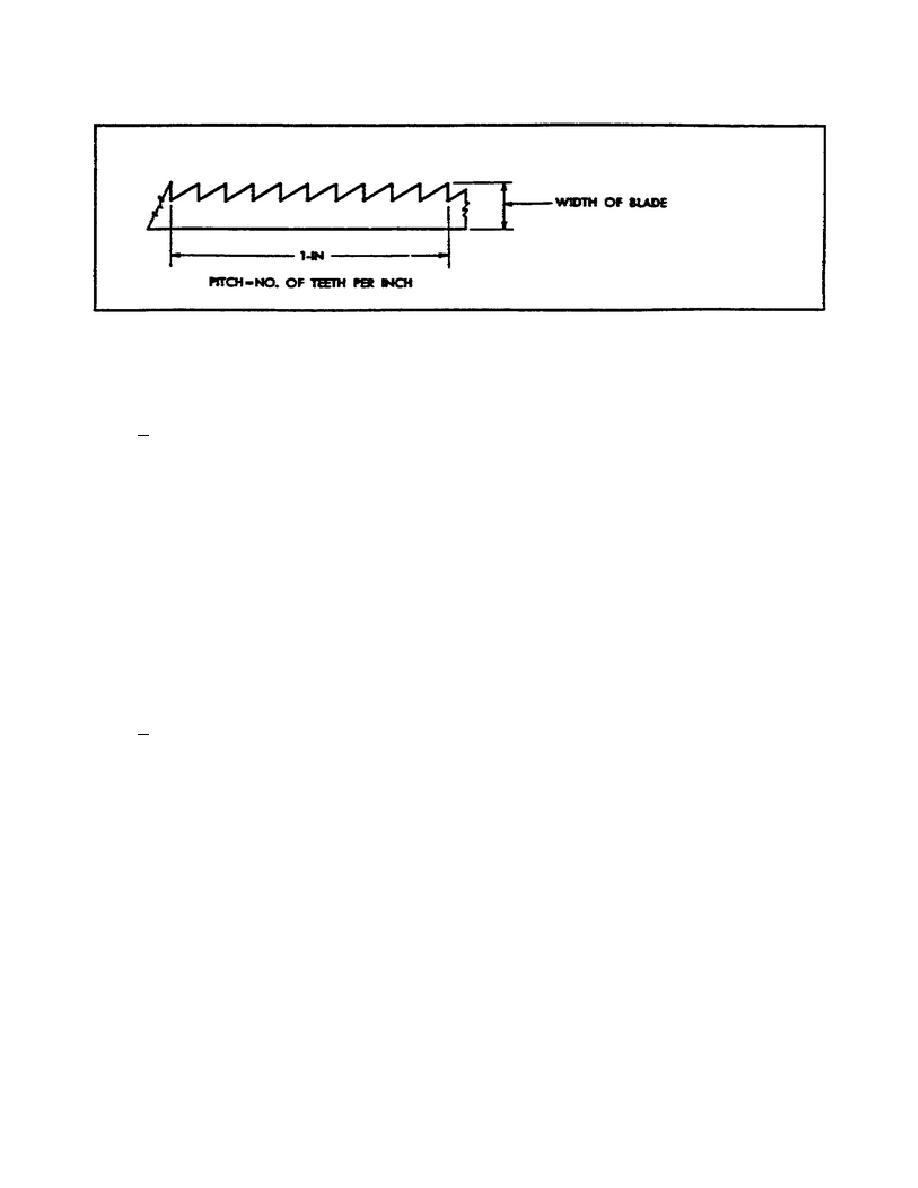

FIGURE 8.

PITCH OF TEETH.

(b) Selecting the Proper Blade. Bandsaw blades are selected according

to the type of material to be cut, the thickness of the material to be cut,

and the sawing operation to be performed.

1 Blade Pitch. Soft or gummy materials and thick stock require coarse

tooth blades to provide adequate chip clearance. Hard materials generally

require finer tooth blades. Fine tooth blades are also necessary if a good

finish is desired. Since two or three teeth of the bandsaw blade must be in

contact with the workpiece at all times to prevent chatter and shearing of

teeth, fine tooth blades are used to cut sheet metal and tubing. If sheet

metal is too thin to meet this requirement with the finest tooth blade

available, the metal should first be mounted on plywood, fiber, or thicker

metal to stiffen it. Table 1, on the following page, may be used as a guide

in selecting the proper pitch bandsaw blade for different metals and metal

thicknesses. If the stock is exceptionally large, coarser tooth blades than

those recommended for solid stock may be used. Remember, two or more teeth

must contact the workpiece at all times to prevent shearing of the blade

teeth.

If the recommended pitch for solid stock fails to meet this

requirement, a blade with finer pitch must be selected.

2 Blade Width.

When straight sawing, the widest blade available of

the proper pitch should be used.

Thinner blades are required for contour

sawing to prevent the body of the blade from rubbing the sides of the cut

when cutting sharp curves.

When curves or radii are to be cut on the

bandsaw machine, the widest blade adaptable to the sharpest radius to be cut

should be used. Narrow blades are more easily broken than wide blades and

should be used only where necessary.

11

Previous Page

Previous Page