BANDSAW OPERATIONS - OD1646 - LESSON 1/TASK 1

rolls of 50 to 500 feet for use on machines that have butt welders for

forming their own blade bands.

Bandsaw blades are also supplied in

continuous welded bands in standard sizes for machines having no provisions

for welding blade bands. All three models discussed in this subcourse have

provisions for welding blade bands.

(a) Characteristics of Blades.

Bandsaw blades are made from special

alloy steel.

The blades are made flexible by annealing the body of the

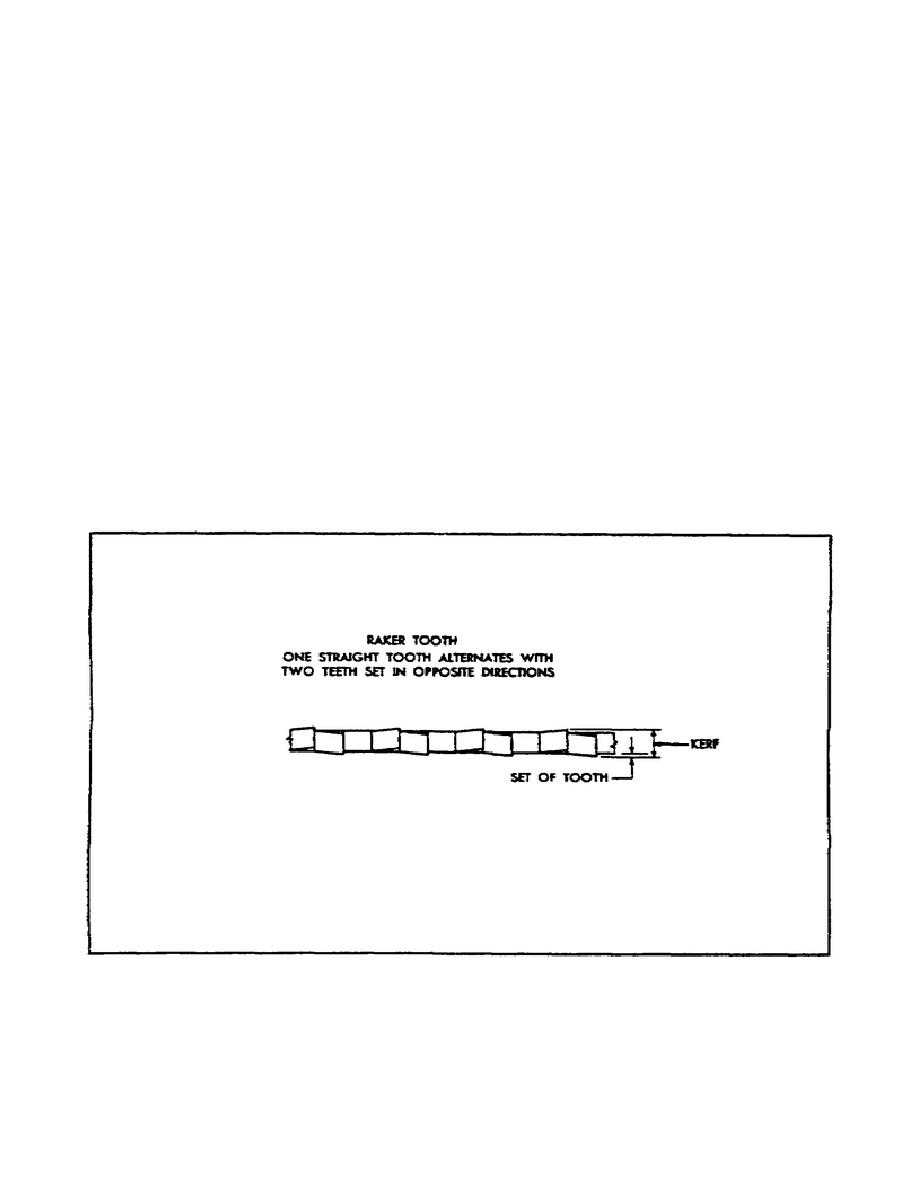

blade and hardening only the teeth. Metal cutting bandsaw blades have their

teeth set to produce a kerf, or cut, slightly wider than the thickness of

the blade to prevent the blade from being pinched by the stock. The setting

of the teeth for most bandsaw blades is called the raker setting.

Raker

tooth blades have one tooth bent to the right, the next tooth bent to the

left, and the third tooth set straight (figure 7).

The pitch of bandsaw

blade teeth is the number of teeth per linear inch of the blade (figure 8 on

the following page). For example, if a blade has 14 teeth per inch (tpi),

it has a pitch of 14, or it may be referred to as a 14-pitch blade. Metal

cutting bandsaw blades range from 6 to 32 teeth per inch. The finer tooth

blades are used for sawing thin stock; the coarse tooth blades are used for

sawing large stock and soft metal.

FIGURE 7.

RAKER TOOTH SETTING.

10

Previous Page

Previous Page