USE/CARE OF HANDTOOLS & MEASURING TOOLS - OD1621 - LESSON 3/TASK 1

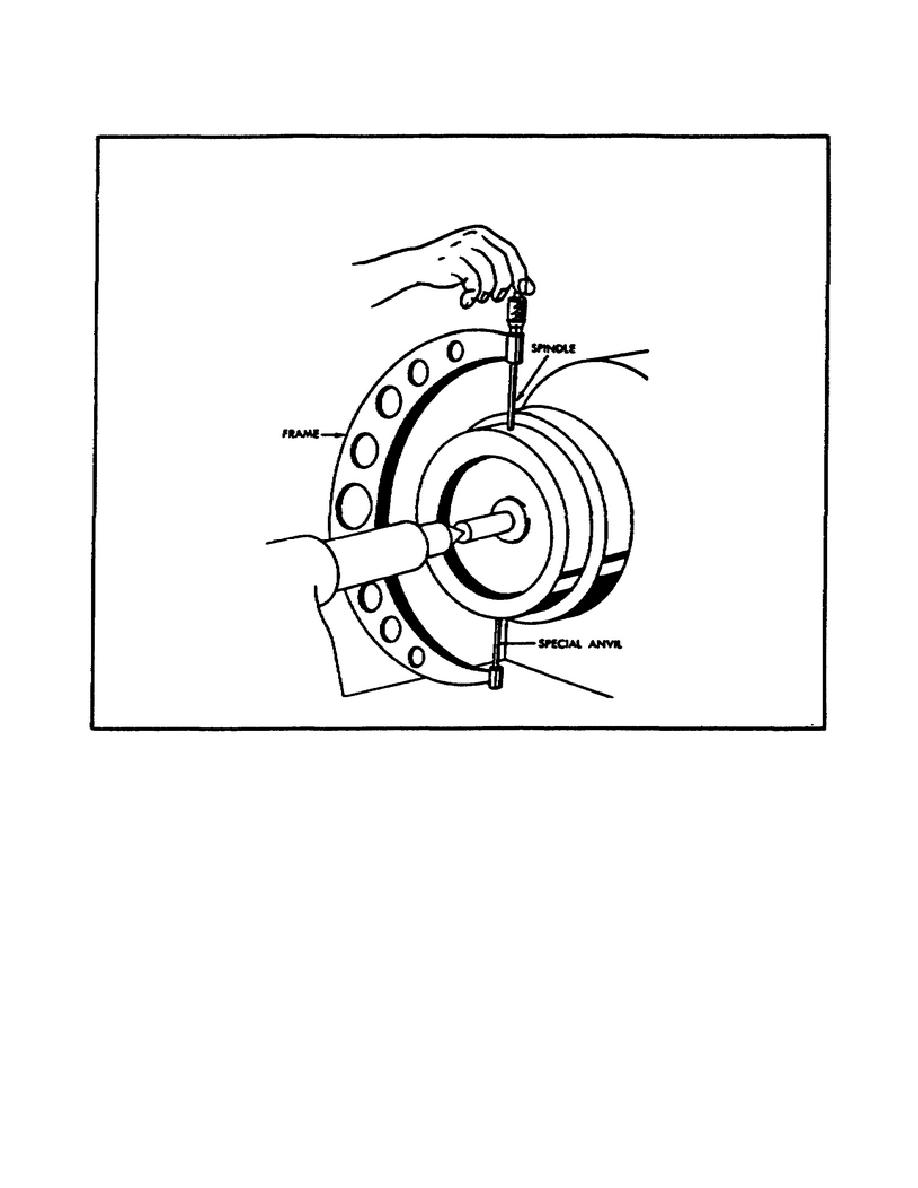

FIGURE 194.

CHECKING DIAMETER OF PULLEY.

(4) Using Inside Micrometer.

The normal procedure when using an

inside micrometer is to set it across a diameter or between the inside

surfaces, remove it, and then read the dimension.

For this reason, the

thimble on an inside micrometer is much stiffer than on a micrometer

caliper--it holds the dimension well.

It is good practice to verify the

reading of an inside micrometer by measuring it with a micrometer caliper.

(a) Figure 195 on the following page shows an inside micrometer

with extension rod being used to check the diameter of a bored hole. Note

the arrows which indicate the directions of movement as the operator feels

for the largest dimension horizontally and the smallest dimension

vertically. Inside micrometers have spherical contact points which require

more practice to "feel" the full diametrical measurement. One contact point

is

248

Previous Page

Previous Page